Allen-Bradley 1336-Series AC Drives

F232120

88

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

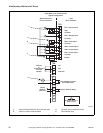

Control Terminal Blocks Description and

Control Logic

Control terminal functions are unique to each Allen-

Bradley Drive. Each drive’s control terminal is

addressed independently.

Control Terminal (TB2/TB3) Function

NOTE: Do not connect drive common terminals

(TB2 or TB3) to ground. There must be no ground

potential difference between source and drive.

Input Mode Parameter

The control terminal functions are determined in part

by the Input Mode parameter #21. Changing this

parameter affects the function of some terminals. All

machines equipped with A-B 1336 drives use Input

Mode “12”.

NOTE: If the Input Mode is changed, power must

be cycled to the drive for the change to take effect.

Speed Selection

Motor speeds are controlled by solid state or

mechanical switch closure inputs to SW1, SW2, and

SW3 in conjunction with STR and STF (direction)

inputs. Refer to Figure 50 and Table 50.

Table 50 designates the preset speed selection based

on the inputs to the control terminals. A disconnected

control terminal will seek the high control voltage

condition (approx. 5 Volts DC). To activate a control

input (i.e., SW1, SW2, etc.), the terminal is connected

to a common terminal (TB3-21, TB3-25, or TB3-29)

to lower the control voltage to a low condition (less

than 1 Volt DC).

The Input Status’ display of 1s and 0s represents the

drive’s display of parameter #55. These inputs can be

viewed in the status display with a Human Interface

Module (HIM or parameter unit). Parameter #55

displays the Input Status. When voltage is high

(inactive) for an input, the status display will read “0”

(Logic 0). When voltage is low (active) for an input,

the status display will read “1” (Logic 1).

Table 50 contains the correct display value for each

function. The sixth display digit from the left in Input

Status parameter does not correspond to a control

input function. Refer to Table 50.

NOTE: The Preset Speed logic is specific to the

type of computer the machine is equipped with (i.e.,

WE-6 or V-Computer).

Balance Output

The AC drive Balance Output is transmitted to the

machine controller by the closure of an on-board

normally open mechanical relay shown in Figure 50.

This action occurs at distribution speed connecting

TB3-16 and TB3-17 when the drive detects an

acceptable balance condition.

Stop Input (Door Interlock /Out-of-Balance

Switch)

The Stop Input function is machine dependent. The

input is used in some machines to disable the drive in

case of an excessive out-of-balance condition; in

others, the input is used to disable the drive when the

door is open. Refer to the applicable electrical

schematic to see the correct wiring of this input. The

control inputs must be removed and reapplied to the

drive for motion after a STOP input has been

interrupted.

Jumpered Inputs

Carefully review electrical schematics when replacing

a drive. Some machine models jumper the STOP,

Motor Temp Input, and/or ENABLE inputs to the

drive (refer to Figure 50).

NOTE: Wire or metal clip jumpers may be used

and can be easily overlooked during a replacement.

WARNING

To reduce risk of electric shock, severe

injury or death, allow machine power to

remain off for three minutes minimum prior

to working in and around AC drive. Proceed

with caution.

W662

WARNING

The controller is supplied with an internal 5V

supply. Dry contacts or open collectors are

required for discrete control inputs. If an

external voltage is applied, component

failure could occur.

W670

CAUTION

MACHINE DAMAGE AND/OR PERSONAL

INJURY. Balance output terminals TB2-16

and TB2-17 should never be jumpered. This

action will force machine beyond designed

tolerances.

W666