Operation Manual Section 4: Removing a transducer assembly

3-9000-744 Rev F September 2013

Steps to remove a transducer assembly from a meter while the meter is under line pressure 23

b. Loosen all four of the lubricator chamber cap screws (Z) on the lubricator

chamber assembly (M) flange from the extractor tool valve assembly (H) flange.

Minimize the rotation of the extractor tool assembly during screw removal.

Remove the three short lubricator chamber cap screws (Z), but do not remove

the one long lubricator chamber cap screw located at the 90

o

position. Loosen

this screw so the end of the screw is flush with the back side of the extractor tool

valve assembly (H) flange.

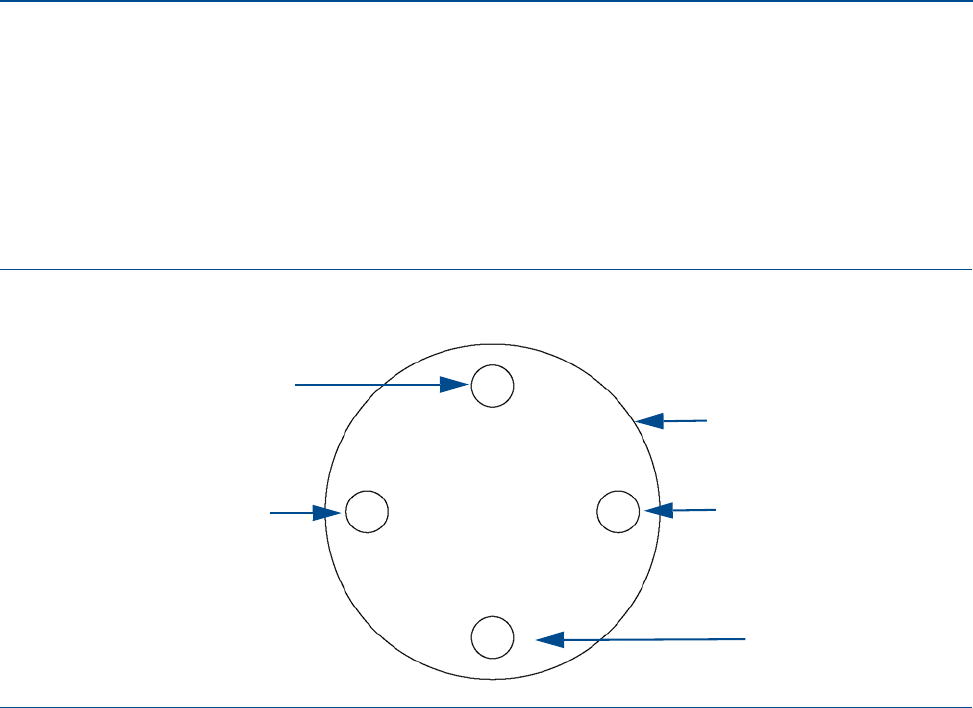

Figure 4-3 Lubricator chamber assembly flange screws

c. Pull on the lubricator chamber assembly (M) to disconnect the lubricator

chamber assembly (M) flange from the extractor tool valve assembly (H) flange.

Pivot the lubricator chamber on the remaining long cap screw.

d. Reinstall a short cap screw at either the 0

o

or the 180

o

position

(see Figure 4-3) and rest the lubricator chamber flange on the reinstalled short

cap screw. This is to leave the lubricator chamber assembly (M) bore exposed.

e. Push on the lubricator chamber extractor rod (N) exposing the transducer

assembly (J), transducer stalk assembly (D) [if fitted], transducer holder (K), and

the end of the extension (L) from the end of the lubricator chamber

assembly (M).

f. Grasp the transducer holder (K) and disconnect the T-slot in the end of the

transducer holder (K) from the extension (L) T end.

90

o

position

270

o

position

Valve assembly flange

0

o

position180

o

position