K400 Issue No. 1 43

4 SERIAL COMMUNICATION

Using the standard digital RS232 interface, the calibrator can be controlled from a

remote computer. By sending commands via the RS232 interface, the calibrator

automatically retrieves temperature readings or modifies any parameter settings

(temperature set-point, temperature reference selection, ramp/step/preset

generation etc.).

4.1 DBC Series - Serial Commands Protocol

ABBREVIATIONS:

aa:

Two digit DBC address in ASCII format. (i.e.. 01).

Send 00 to overwrite every other address.

par:

Parameter. Command depending format.

R/W:

Read and Write command

R:

Read Only command

n.a.:

Not Applicable

[ ]:

Every parameter enclosed in square bracket are optional

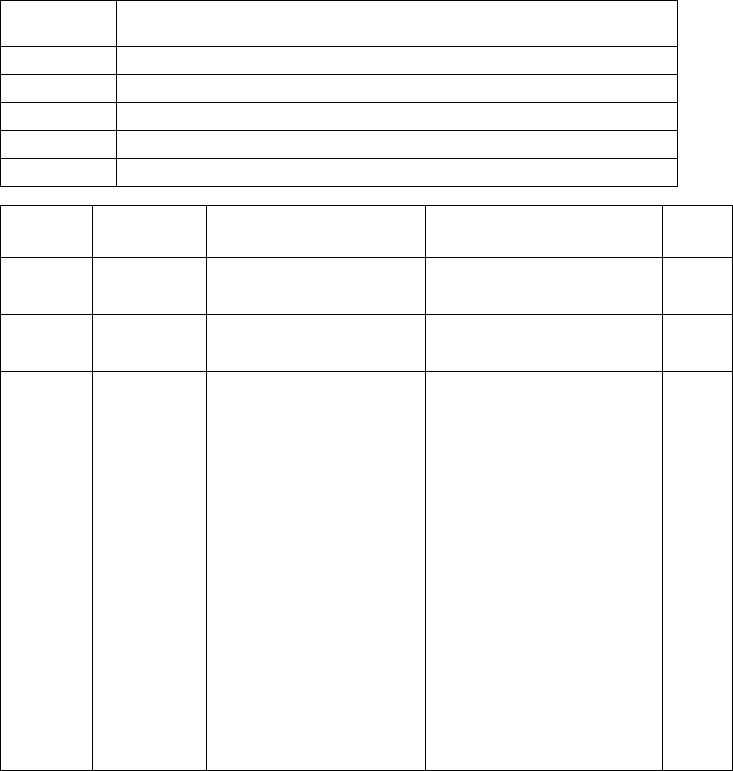

Command

Flow

Command Parameters Description

Model

(TS/TC)

Write

Read

Query

*aaEM=par

*aaEM?

!aaEM=par

Par = 0 Absolute error °C

1% of span

2% of readings

R/W - Error Computation Mode

(MM command to set CAL mode)

TC

TC

TC

Write

Read

Query

n.a.

*aaER?

!aaER=par

Par = floating point R – Get Error Value

(Mode selected by EM command)

TC

Write

Read

Query

*aaICc=par

*aaICc?

!aaICc=par

c =1 Regulator (optional)

2 Measure

par = 0 NONE

1 n.a.

2 T/C +CJ

3 T/C no CJ

4 RTD 3 Wires

5 RTD 4 Wires

6 RES 3 Wires

7 RES 4 Wires

8 mV

9 n.a.

10 n.a.

11 n.a.

12 mA

13 n.a.

14 Switch

15 n.a.

16 n.a.

17 Reference RTD 4 wires

18 V

R/W –Input Channel

No measure

Thermocouple + Cold Junction

Thermocouple without Cold Junct.

Thermoresistors 3 wires

Thermoresistors 4 wires

Resistors up to 400 Ω 3 wires

Resistors up to 400 Ω 4 wires

mV input

mA input

Switch mode

User Thermoresistors 4 wires

Volt Input

TS

TC

TS

TC

TC

TS/TC

TS/TC

TC

TC

TC

TC

TS/TC

TS/TC

TS/TC

TC