2 K400 Issue No. 1

reference) and a possible electrical feedback from a device under test (i. e.

temperature probes, temperature transmitters). An error calculation, with scaling

function, allows the user to check immediately the accuracy specification of the unit

under test. A 24 V auxiliary excitation provides power for temperature transmitters

under test.

1.1 Automatic Calibration

An RS232 computer interface enables a Calibration Management Software to

provide automatic calibration procedures, typically with the following capabilities:

• Creation of instrument details

• Creation of test procedures and work orders

• Analysis of devices due for calibration

• Printing of calibration reports

• Export functions

Refer to section 4 SERIAL COMMUNICATION for remote control of this instrument.

1.2 Parts Identification

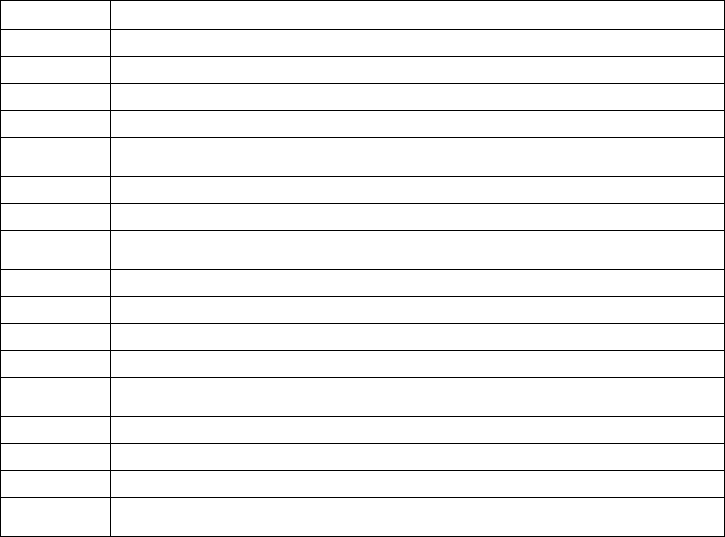

Key to Figure 1-1

Fig no. Description

1

Dry well with insert

2

Protection grid

3

Carrying handle

4

4 mm socket for T/C, RTD and ohm connection, with CJ compensation

5

Tactile key-pad for direct selection of all the operating function (ramps, steps, preset

values, switch test, help, set-up) and to set temperature values

6

Cooling fan

7

Support feet (4)

8

Protection fuse (115 Vac 2x12.5 AT and 230 Vac 2x6.3 AT for DBC 650

(115 Vac 2x1.6 AT and 230 Vac 2x3.15 AT for DBC 150)

9

Main power selector 100 - 120 Vac and 220 - 240 Vac, 50/60 Hz

10

Power supply on/off switch

11

Main power socket: to connect the standard power cable

12

RS232 serial communications interface

13

Cursor (arrow) keys to select operating functions from the main menu and to move the

selection cursor through the menus

14

Digital display with Multi-language user interface

15

Switch test connection, suitable to connect test leads supplied as standard

16

4 mm socket for voltage and current input with 24V dc auxiliary excitation

17

Lemo connection for external reference probe: suitable for connecting PT 100 probes

with 3 or 4 wires, supplied with standard mating connector ( B1, B2 and B3 options)