6-10

TEST #2 Log Valve

This test checks the electrical connections to

the valves, and the valves themselves.

1. Check the relays and electrical connec-

tions to the valves by performing the steps

under Diagnostic: Manual, then Manual:

Water Valves. Each step in the test ac

-

tivates a group of valves. The following

steps assumes one (or more) valve(s)

failed to turn on.

2. For the valve(s) in question check the in-

dividual solenoid valves:

Unplug washer or disconnect power.

Disconnect connector P1 and P2 from

the machine/motor control.See Figure

4, page 6-16.

Check harness connection to solenoid

valves.

3. Check resistance of valve coils at con-

tacts P1 and P2 shown in the Wiring Dia

-

gram on page 7-1. Resistance values

should match those shown.

If resistance readings are tens of ohms

outside of range, replace the entire log

valve assembly.

If resistance readings are within range,

replace the machine/motor control as

-

sembly.

4. Reconnect connectors P1 and P2 to the

machine/motor control.

TEST #3 Motor Circuit

This test checks the wiring to the motor and

rotor position sensor; and the motor and rotor

position sensor themselves.

NOTE: Drain water from tub.

1. See Activation of Manual Diagnostic Test

Mode, and check the motor and electrical

connections by performing the Spin test

under Manual: Motor. The following steps

assumes that this step failed.

2. Unplug washer or disconnect power.

•

•

•

•

•

3. Check to see if basket will turn freely.

If basket turns freely, go to step 4.

If basket does not turn freely, deter

-

mine what is causing the mechanical

friction or lock up.

4. Remove the console to access the ma

-

chine/motor control assembly. See Ac

-

cessing & Removing the Electronic As

-

semblies.

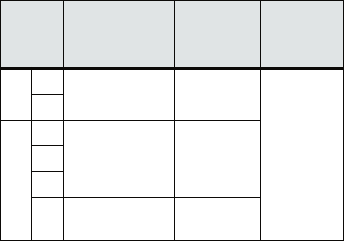

5. Visually check that the P5 and P10 con-

nectors are inserted all the way into the

machine/motor control.

If visual checks pass, go to step 6.

If visual checks fail, reconnect P5 and

P10 and repeat step 1.

6. Visually check that the P5 and P10 con-

nectors are inserted all the way into the

machine/motor control.

With an ohmmeter, verify resistance

values as shown below:

•

•

•

•

•

7. Tilt machine forward to access the bottom

of the machine and the drive motor area.

See Figure 1 on page 6-13. Remove the

motor bolt, then the motor cover to ac

-

cess the motor connections. See Figure

2 on page 6-13.

8. Visually check the mounting bracket and

electrical connections to the motor and

rotor position sensor board.

If visual check passes, go to step 9.

If visual check fails, reconnect the elec

-

trical connections, reassemble stator

and motor cover and repeat step 1.

•

•

Check

betwee

n

connector

pins

Resistance values

should be:

Go to

step 7 i

f

values are:

Go to

step 12 if

:

P5

1-5

31 Ω ± 5 Ω

Much higher

than 31Ω

Resistances

at all

connectors

are correct

1-3

P10

6-5

15 k

Ω ± 100 Ω

Much higher

or muc

h

lower than

15 k

Ω

6-4

6-3

1-7

600 Ω t

o

21.2 k

Ω

Out of range