M4557 - Model 9210 Nitriding Controller

SSi Manual SERIES 9210-M4557-Nitriding Page 48 of 48

Chapter 6 - APPLICATIONS INFORMATION

Standard Event Assignments

To simplify operation and maintain consistency, SSI has adopted the following event assignments.

Event 0 Nitrogen Addition

Event 1 Ammonia Addition

Event 2 Disassociated Ammonia Addition

Event 3 Hydrogen Addition

Event 4 Spare

Event 5 Spare

Event 6 Spare

Event 7 Sample Cell Enable

Event 8 Spare

Event 9 Spare

Event 10 Spare

Event 11 Spare

Event 12 Spare

Event 13 Spare

Event 14 Spare

Event 15 Spare

Typical Nitriding Instrument Designations

Instrument 7 – Nitrogen

Instrument 8 – Ammonia

Instrument 9 – Disassociated Ammonia

Nitriding Recipes/Programs

Nitriding Recipes can be broken down into three stages, Startup, Nitriding and Shutdown

In the Startup phase of the recipe, the furnace starts to heat up and is purged with Nitrogen. As a general

rule to assure safe operation of the furnace, the furnace should be purged with Nitrogen long enough to

allow for 5 to 7 volume changes. This ensures that it will be safe to add Ammonia and/or Dissociated

Ammonia when required. This purge time is determined by calculating the furnaces volume and dividing by

the Nitrogen Flow. The startup phase can also start adding ammonia once the desired purge time and

temperature has been achieved.

In the Nitriding process stage of the recipe, the temperature and %Dissociation/Kn setpoints are set and

the Soak times are set as well. This phase will also enable the Trim enable feature for ammonia to allow

for control of the furnace atmosphere to setpoint.

After the Nitriding process stage, the shutdown routine will run. This typically involves, shutting off the

Ammonia and Dissociated Ammonia, turning on Nitrogen and lowering the temperature setpoint to allow

the furnace to cool. This stage will also sound an alarm indicating the process is complete.

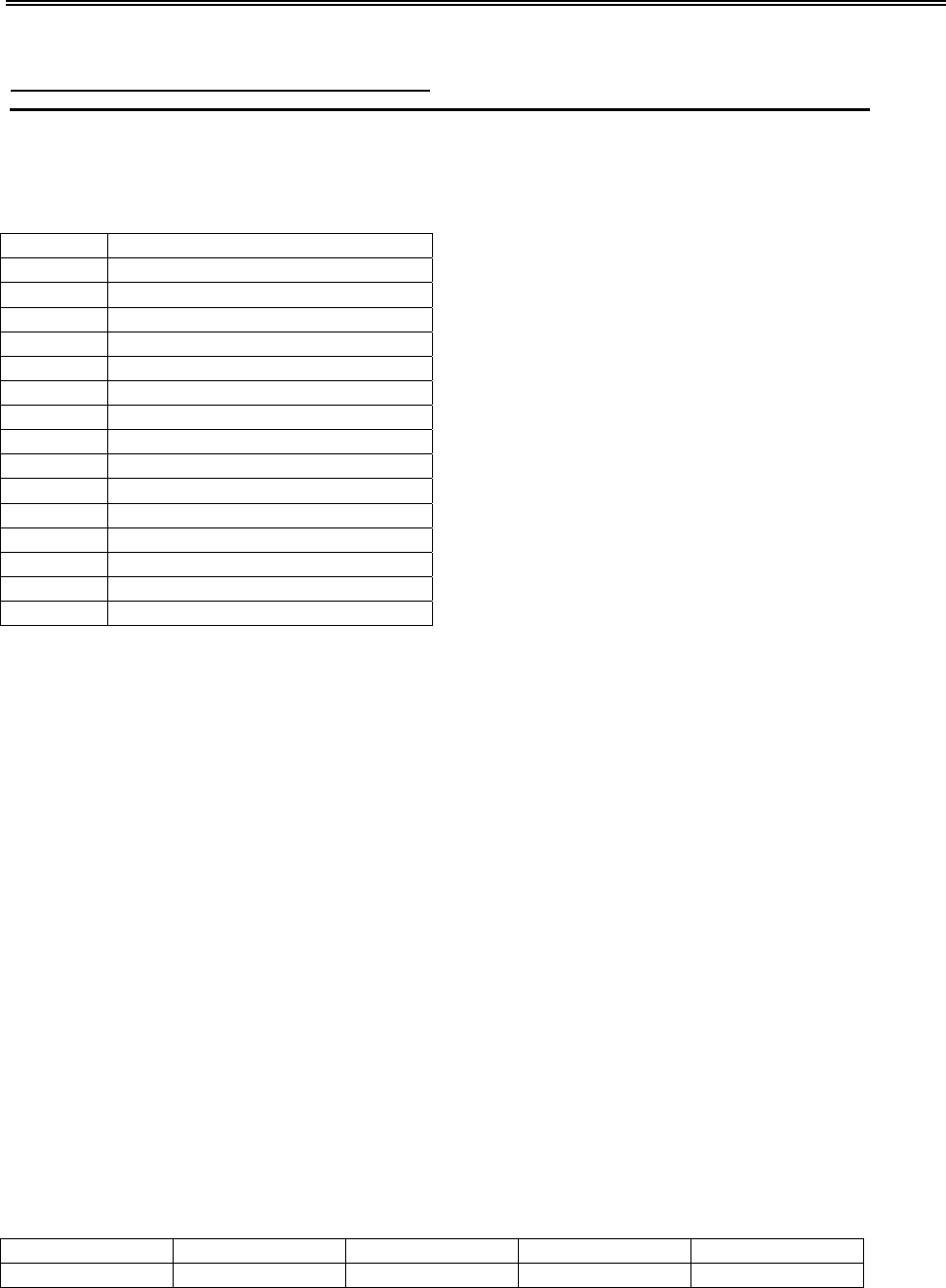

SAMPLE RECIPES

Recipe 1

Step OpCode Temp ATM Options

S1 Go-Sub 50