M4557 - Model 9210 Nitriding Controller

SSi Manual SERIES 9210-M4557-Nitriding Page 33 of 33

numeric keypad that can range from 0 to 100. The “Auto Valve Event” selection will allow the user to

either turn the valve event on or off with a running program using the

Set Valve

opcode. This can be

either On or Off.

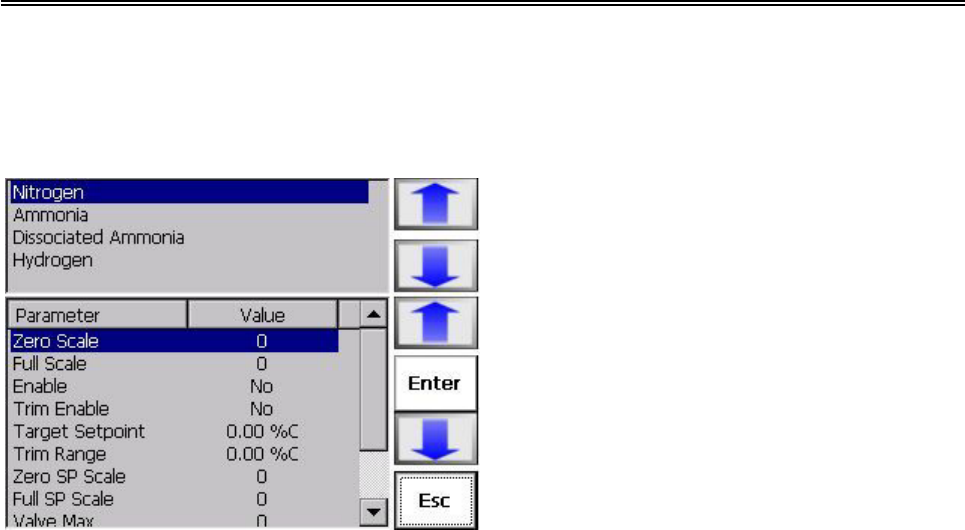

Valve Setup

This screen is used to setup the 9210 based on how

the flow meter boards are setup. This allows the

9210 to know how display each individual gas flow.

There are four gases to select: Nitrogen,

Ammonia, Dissociated Ammonia, and

Hydrogen. Once a gas flow has been selected,

the values for that flow will be displayed in the

lower level. The “Zero Scale” selection will allow

the user to set the zero scale for the flow. This will

display a numeric keypad that can range from 0 to

30,000. The “Full Scale” selection will allow the

user to set the full scale for the flow. This will

display a numeric keypad that can range from 0 to

30,000. Selecting the “Enable” selection will allow

the user to enable the flow. This will cycle between

Yes and No. Selecting the “Trim Enable” selection

will allow the user to enable the trim flow. This will cycle between Yes and No. The “Target Setpoint”

selection will allow the user to set the target setpoint for the flow. This will display a numeric keypad that

can range from 0 to 2000. The “Trim Range” selection will allow the user to set the trim range for the

flow. This will display a numeric keypad that can range from 0 to 2000. The “Zero SP Scale” selection will

allow the user to set the zero scale for the setpoint for the flow. This will display a numeric keypad that

can range from 0 to 30,000. The “Full SP Scale” selection will allow the user to set the full scale for the

setpoint for the flow. This will display a numeric keypad that can range from 0 to 30,000. The “Valve

Max” selection will allow the user to set the valve maximum for the flow. This will display a numeric

keypad that can range from 0 to 30,000. The “Flow deviation setpoint” selection will allow the user to set

the setpoint for the flow deviation alarm. This will display a numeric keypad that will range from 0 to

30,000. A setpoint of 0 will disable the deviation alarm for the valve. The “Dev. Alarm delay (sec)”

selection will allow the user to set the number of seconds before the deviation alarm will sound. This will

display a numeric keypad that will range from 0 to 30,000.

Note: The deviation alarm delay is entered in

1/10 minutes (6 seconds), so a 2 entered will be displayed as 12 seconds

.

User Calibration

The user will need a thermocouple calibrator capable of outputting a thermocouple signal to calibrate the

zero, span or cold junction value of the 9210 instrument. The user will need to connect the calibrator to

one of the inputs on the instrument that will be calibrated. It is recommended to let everything (calibrator

and instrument) sit for approximately thirty minutes to allow the temperature to achieve equilibrium. Set

up the calibrator for the specific thermocouple type of the thermocouples in the 9210 instrument, i.e. type

K, type J, etc. Then, source a specific temperature, like 1000 °F, or millivolt to the connected input. It is

recommended that the actual temperature used be similar to an appropriate process temperature. For

example, if your equipment normally operates at 1700 °F, then perform the cold junction calibration using a

1700 °F signal. It is important to note that when performing a zero or span calibration,

do not use

regular

thermocouple wiring. Instead, use any kind of regular sensor wire, or even regular copper wire. To

perform the calibrations, the user will need a calibrator that is capable of outputting volts, millivolts, and

temperature.

Note: The buttons on the screen always have the same functionality. The ÅBack button will display the

previous screen, if any. The Skip button will skip the current screen and display the next screen, if any.

The Next → button will display the next screen, if any. The Done button will close out the

User