450260-1 www.amdry.com 15

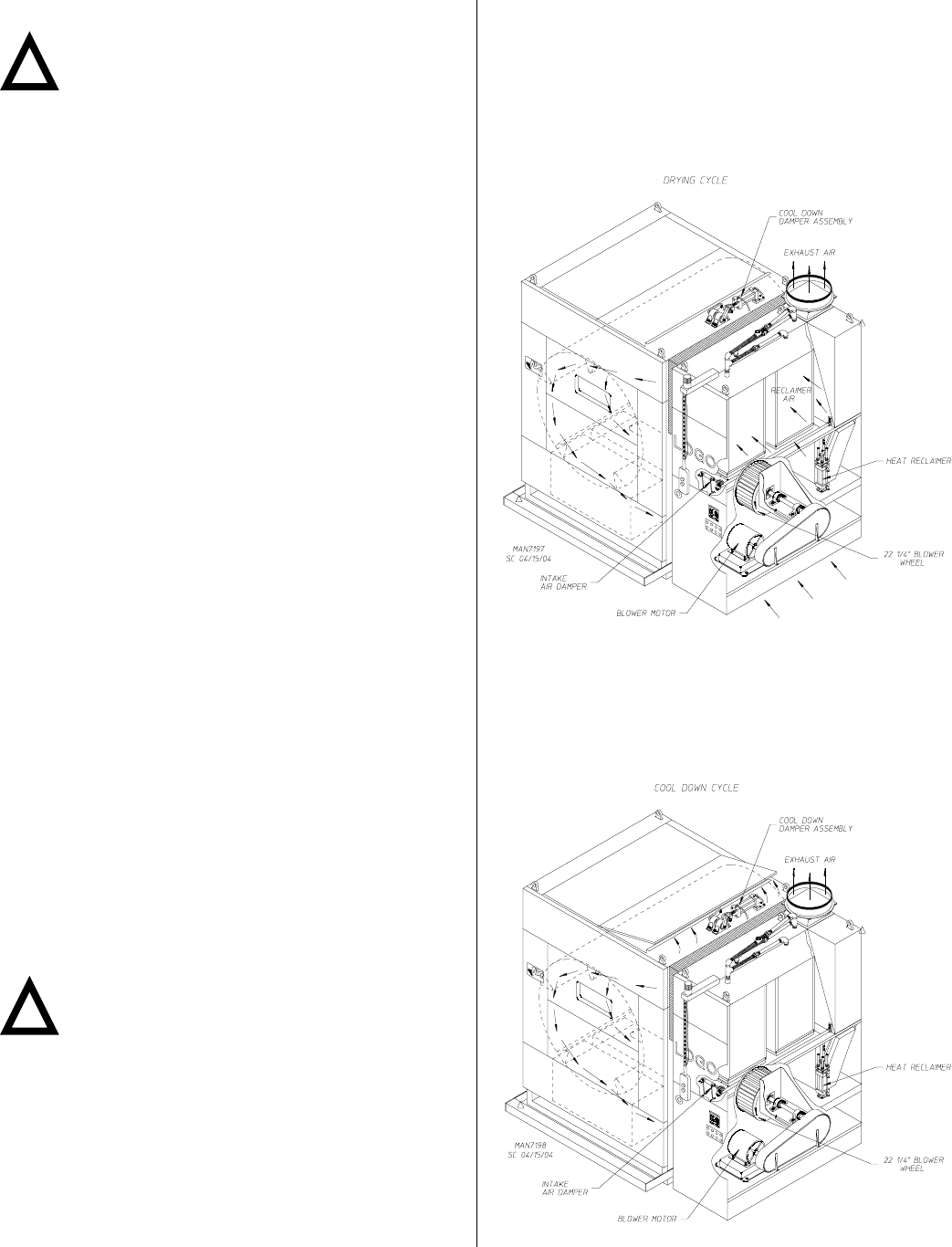

Heat Mode Air Flow

During a call for heat, solenoid S10 turns on and air first

enters the dryer on the bottom right side of the dryer. The air

then passes through the open inlet air damper, then passes

through the six (6) steam coils to heat the air. Next, the air

enters the tumbler (basket) heating the load inside. The air

then goes through the lint screen. Once the air is filtered by

the lint screen it is forced out of the exhaust by the blower. A

percentage of the air being exhausted gets reheated by the

heat reclaimer to be used again. (Refer to the Drying Cycle

illustration below).

Temperature Set Point/Cool Down Mode

During a cool down mode, solenoid S10 turns off and solenoid

S9 turns on. In this mode, the air enters through the cool

down damper on top of the dryer and enters the tumbler

(basket). The air then passes through the lint basket and

gets pushed out of the exhaust by the blower wheel. (Refer

to the Cool Down Cycle illustration below).

Natural Gas and Liquid Propane (L.P.)

Gas Conversion Instructions ________

Impor tant

Conversion must be performed by competent

technicians in accordance with local and state

codes.

1. Loosen the screw on the high fire valve cap that doesnt

have the paint drop.

2. Turn the cap to the + to increase the pressure or to the

- to decrease the pressure.

3. Take the pressure reading at the outlet of the valve.

4. Tighten the screw to lock the cap once the pressure is

set to 1.25 inches of water column (W.C.) for L.P. gas.

Steam Heat System _________________

The steam dryer uses six (6) steam coils to produce a heat

input of 60 Bhp (boiler horsepower). The dryer utilizes three

(3) separate dampers to direct air in the drying process or

cool down process of a cycle.

The first damper is the cool down damper located on the top

of the dryer, and is used to bring fresh, room temperature air

into the tumbler (basket). When the dryer is in the cool down

mode or has reached its set point temperature, the damper

will be in the open position further reducing increases in

tumbler (basket) temperature. When there is a call for heat,

the damper closes, thereby requiring all of the air entering

the tumbler (basket) to go through the steam coils.

An inlet air damper is located in the middle of the right hand

section of the dryer. During a call for heat, this damper opens,

which allows ambient air into the dryer, which then goes

through the steam coils, heating the air. During cool down,

or if the dryer has reached its set point temperature, the

damper closes eliminating air from going through the steam

coils.

The heat reclaimer is used to divert a portion of the exhausted

air and run it through the steam coil, reheating the air.

Depending on the stroke at which the heat reclaimer has

been set, the amount of reclaimed air will vary. The heat

reclaimer is only opened during a call for heat. Once the

dryers' set point temperature is reached or during a cool down

mode the heat reclaimer will be closed.

Steam Coil pH Level

The normal pH level for copper type steam coils must be

maintained between a value of 8.5 to 9.5. For steel type

steam coils the pH level must be maintained between a value

of 9.5 to 10.5. These limits are set to limit the acid attack of

the steam coils.

Impor tant

Coil failure due to improper pH level will void the

warranty.

!

!