14 American Dryer Corp. 450260-1

Burner Fan Motor

Burner Fan Motor Replacement

1. Discontinue electrical service to the dryer.

2. Remove the four (4) #8-18 x 7/16" TEK screws which

secure the inlet ring to the combustion air blower

housing.

3. Remove the two (2) 1/2-20 left hand jam nuts as well as

the 1/2-inch flat washer.

4. Remove the 6-1/4" squirrel cage fan.

5. Remove the motor cover plate to reveal the wiring.

6. Mark and identify wiring for correct replacement on to

the new motor.

7. Remove the cord grip and wiring harness from the motor.

8. Remove the four (4) 3/8-16 x 3/4" hex head bolts securing

the motor to the combustion air blower housing.

9. To install new burner fan motor, reverse steps.

10. Reestablish electrical service to the dryer.

Burner Fan Squirrel Cage

Burner Fan Squirrel Cage Replacement

1. Discontinue electrical service to the dryer.

2. For removal of the 6-1/4" squirrel cage fan, follow Step

#2 through Step #4 of the Burner Fan Motor Replacement

instructions above.

3. For replacement of new 6-1/4" squirrel cage fan, reverse

Step #4 through Step #2 of the Burner Fan Motor

Replacement instructions.

4. Reestablish electrical service to the dryer.

Burner Fan Electrical Components

Burner Fan Thermal Magnetic Starter (TMS)

The TMS is used as a safety device to manually disconnect

the motor so that it will be protected from damage in the

event of a locked rotor condition. The overload has a dial

setting on the face of the device. To set the overload, refer to

the specific electrical diagram. The overload is specifically

designed for motor applications. It has a current curve built

into it so the initial high current draw by the motor will not trip

the overload. On the face of the overload are two (2) push-

buttons; "START" (Black or Tan) and "STOP" (Red - 0). The

overload has to be in the "START" mode for the motor to run.

Thermal Magnetic Starter (TMS) Replacement

1. Discontinue electrical service to the dryer.

2. Mark L1, L2, L3, and T1, T2, T3 on the wires to the TMS

for correct replacements.

3. Set the amp (amphere) rating on the TMS according to

the electrical schematic supplied with the dryer.

4. To remove the TMS, pull the tab on the bottom of the

TMS and lift upwards.

5. To install the new TMS, reverse Step #4 through Step

#2.

6. Reestablish electrical service to the dryer.

Auxiliary Contact Block

The auxiliary contact block is mounted on the side of the

overload. Its function is to sense an overload trip, thereby

triggering a safety fault which will disable the drying cycle.

Auxiliary Contact Block Replacement

1. Discontinue electrical service to the dryer.

2. Remove the TMS from the din rail by pulling the tab on

the bottom of the auxiliary contact block and lift upwards.

3. Remove the two (2) wires going to the auxiliary contact

block and label them for correct reinstallation.

4. There are two (2) types of auxiliary contact blocks: one

type has a screw and the other type has a clip. In either

type, disassembly and assembly is recommended with

the TMS in the stop position.

5. To install the new auxiliary contact block, reverse Step

#4 through Step #2.

6. Reestablish electrical service to the dryer.

Varistor (Metal Oxide Varistor [MOV])

The metal oxide varistor (MOV) is used to suppress any

inductive electrical spikes produced by the energizing and

collapsing of coil voltage.

Varistor (Metal Oxide Varistor [MOV]) Replacement

1. Discontinue electrical service to the dryer.

2. Loosen the screws marked A1 and A2 on the contactor.

3. Verify that no additional wires were inadvertently

removed.

4. To install the new metal oxide varistor (MOV), reverse

Step #3 through Step #1.

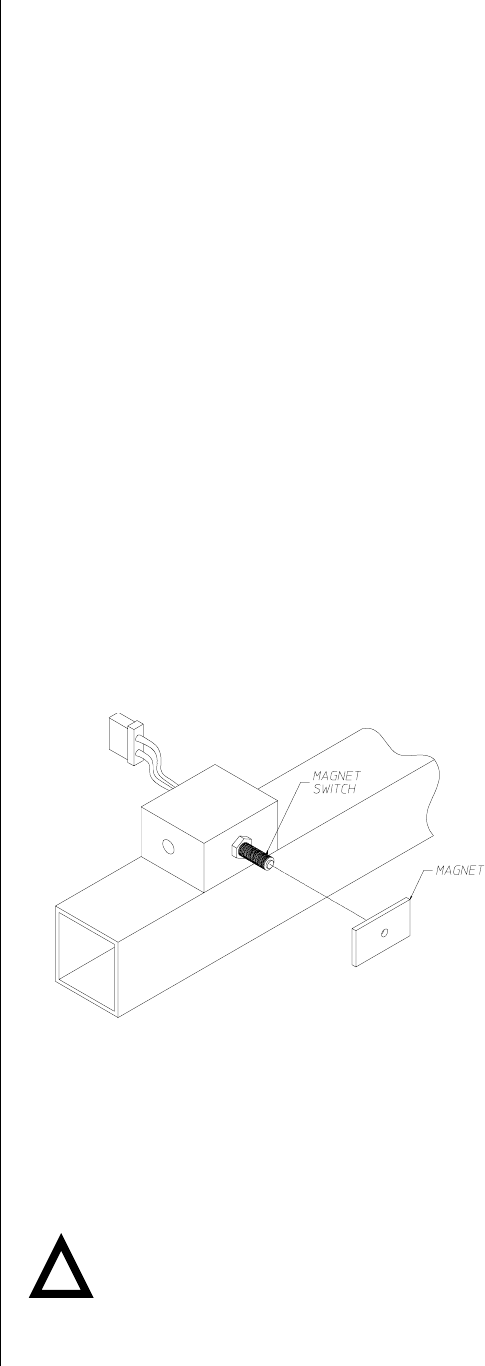

Burner Door Switch

The burner door switch is a part of the dryer's safety circuit. If

at any time during a drying cycle the burner doors are open,

the controller will shut the dryer down and display "FRONT

DOOR OPEN." (Verify that the burner door switches are not

out of adjustment.)

Burner Door Switch Adjustment

1. With burner doors closed, verify if PLC (Programmable

Logic Controller) Input #8 is ON or FDRC red light

emitting diode (L.E.D.) on control board is on.

2. If indicator shows that the door is open , then adjustment

is needed. Remove cover from the switch box.

Note

Adjust one switch at a time.

3. Adjust the switch until the magnet on the door activates

the switch.

4. Put the cover back and close the burner doors.

MAN7175

SC 04/1/04

!