450260-1 www.amdry.com 11

Burner Fan Air Switch

The differential in air pressure is measured by the burner fan

air switch, which is located next to the burner fan motor. If the

combustion air is inadequate, this switch will prevent ignition.

The setting of this switch is adjustable, and it should be set

at approximately 0.59-inches (15 mm) of water column (W.C.)

because of slight variances in spring tension characteristics,

range settings, and markings are nominal.

Burner Fan and Motor

The combustion air is produced by a 6-1/4" squirrel cage fan

attached to a 1-1/2 hp, 3,600 rpm motor. The motor must

spin counterclockwise (CCW) as viewed from the rear of the

motor.

Combustion Air Lint Filter

The combustion air lint filter is made of a fine mesh stainless

steel screen which must be cleaned regularly. This screen

prevents any lint from entering the burner box.

Combustion Air Damper

To produce the required combustion airflow, this damper can

be adjusted. Remove the screen to get access to the damper.

Moving the damper closer to the blower inlet opening will

reduce the combustion airflow, and moving it away from the

blower inlet opening will increase the airflow. To measure

the combustion airflow, attached a manometer to the air

pressure tap on the burner box. The air pressure should

measure 1.25- inches (31.75 mm) to 1.5-inches (38.1 mm)

W.C.

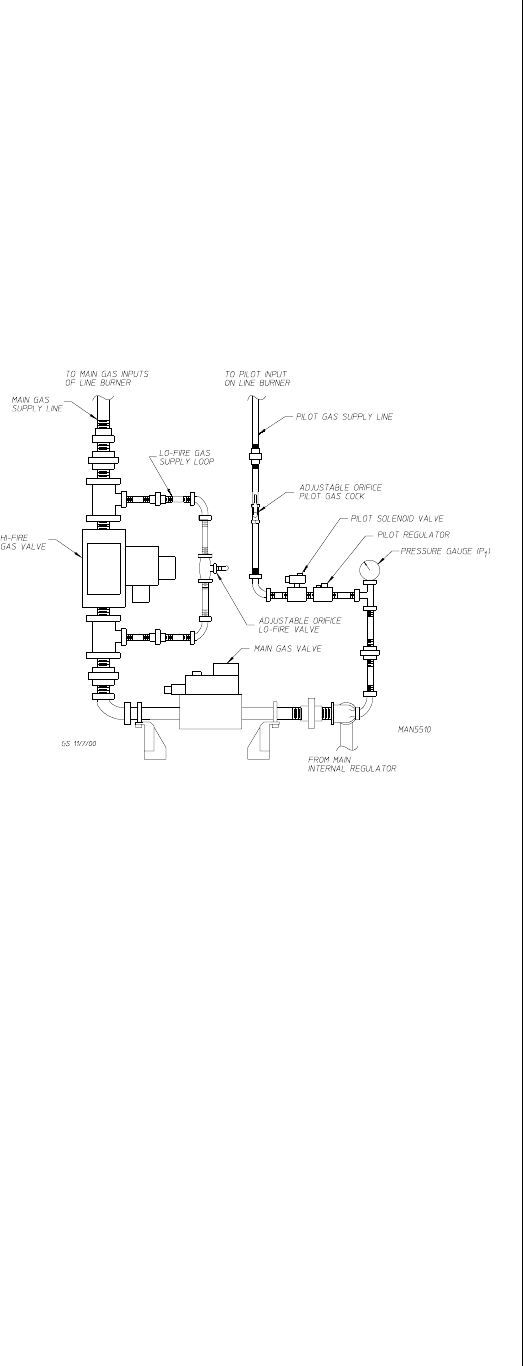

Pilot Gas Supply Line ________________

The pilot gas supply line consists of a manual shutoff valve,

pressure regulator, electric solenoid valve, back-loaded

pressure regulator, and an adjustable gas cock.

The gas pressure in this line should be approximately

3.5-inches (88.9 mm) W.C. for natural gas and 1.5-inches

(38.1 mm) W.C. for liquid propane (L.P.) gas. This will provide

a bushy pilot flame, which produces a signal through the

flame rod that is converted to 3 to 11 volts DC in the burner

controller module (BMC).

This flame can be adjusted in two (2)

ways

Pilot Inlet Pressure Regulator

Remove the cap and turn the slotted adjustment screw

clockwise (CW) for more gas and counterclockwise

(CCW) for less gas.

Adjustable Pilot Gas Cock

Remove the cap and turn the slotted adjustment screw

clockwise (CW) for less gas and counterclockwise (CCW)

for more gas.

The pilot line contains a back-loaded pressure regulator with

an impulse line connected to the gas burner inlet. The

regulator will maintain a constant pilot supply pressure in

the burner due to an increase in temperature. Do not adjust

this regulator.

Main Gas Supply Line ________________

The main gas supply line consists of a pressure regulator,

two (2) motorized shutoff valves, HI/LO gas pressure switch,

manual shutoff valve.

The gas pressure at the burner should be 2.5-inches

(63.5 mm) W.C. for natural gas and 1.25-inches (31.8 mm)

water column for L.P. gas. This pressure is measured by a

manometer at the manual shutoff valve just top motorized

valve.

Motorized Gas Valve

The two (2) 2-inch F.P.T. motorized valve are ON/OFF gas

flow control valves. The valves motors operate on 120 VAC

and are electrically cascaded so that upper valve will not

open until lower valve has fully opened. A limit switch inside

the lower motorized valve provides the signal that the valve is

fully opened. These valves will open only when the BCM is

receiving a signal from the flame rod proving that the pilot

flame is established. The bypass of the second valve allows

for the low fire.

Top Motorized Gas Valve

The valve sets the gas rate of 2,800,000 Btu/hr (705,290

kcal/hr). To achieve this rate, the gas pressure must be set

for 2.5-inches (63.5 mm) water column for natural gas and

1.25-inches (31.8 mm) W.C. for L.P. gas. To adjust. loosen

the pan head screw located on the front of the top motorized

valve, while holding the valve body, turn the flow adjustment

clockwise (CW) for less gas and counterclockwise (CCW)

for more gas. Retighten the pan head screw when correct

gas flow is achieved. There is a switch located on the back of

the top gas valve that verifies valve closure. The BCM will go

into a system unsafe error and the burner will not begin a

burner sequence.