47

M414905

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Steam Requirements

NOTE: Machines require a constant 80 to 100 psig

(5.62 to 7.03 kg/sq cm) steam service for optimum

operation. The maximum allowable steam pressure

for use with 60 Hertz or 50 Hertz tumblers is

125 psig (8.6 bar). In no case may the pressure

exceed the above value.

Obtain specific steam service pipe sizes from steam

system supplier or a qualified steam fitter.

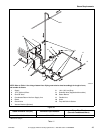

● Refer to Figure 23 for proper steam pipe

configurations.

● To prevent condensate draining from headers to

tumbler, piping should have a minimum 12 inch

(305 mm) rise above respective header. Do not

make steam connection to header with a

horizontal or downward facing tee or elbow.

● Whenever possible, horizontal runs of steam

lines must drain, by gravity, to respective steam

header. Water pockets, or an improperly drained

steam header will provide wet steam, causing

improper operation of tumbler. If pockets or

improper drainage cannot be eliminated, install a

bypass trap to drain condensate from the low

point in the steam header to the return.

● In both steam supply and steam return line, it is

recommended that each have a pipe union and

shut-off valve. This will enable you to disconnect

the steam connections and service the tumbler

while your laundry facility is in operation.

● Connect the steam solenoid valve to the related

steam coil inlet connection with nipples, flex

hoses, unions and tees.

● Strainers may require cleaning due to materials

from hoses or pipes.

● Install vacuum breaker (optional), bucket trap

with built-in strainer and check valve. For

successful operation of tumbler, install trap

18 inches (457 mm) below coil and as near to the

tumbler as possible. Inspect trap carefully for

inlet and outlet markings and install according to

trap manufacturer's instructions. If steam is

gravity returned to boiler, omit trap but install

vacuum breaker and check valve in return line

near tumbler. Gravity return requires entire return

plumbing be below steam coil outlets.

● Install union and shut-off valve in return line and

make final pipe connections to return header.

NOTE: To prevent water hammering, route return

lines below outlets of steam coils.