29

M414905

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Exhaust Requirements

Layout

Whenever possible, install tumblers along an outside

wall where duct length can be kept to a minimum, and

make-up air can be easily accessed. Construction must

not block the airflow at the rear of the tumbler. Doing

so would prevent adequate air supply to the tumbler

combustion chamber.

Make-Up Air

A tumbler is forced air exhausted and requires provisions

for make-up air to replace air exhausted by tumbler.

IMPORTANT: Do not obstruct flow of combustion

and ventilation air.

Make-up air openings with louvers will restrict

airflow. The opening must be increased to compensate

for area taken up by louvers.

Make-up air openings in rooms containing tumbler(s)

and/or gas fired hot water heater or other gravity vented

appliances must be increased sufficiently to prevent

downdrafts in any of the vents when all tumblers are in

operation. Do not locate gravity vented appliances

between tumbler(s) and make-up air openings. If it is

necessary to duct make-up air to tumbler(s), increase

area of duct work by 25% to compensate for

restrictions in air movement.

Venting

IMPORTANT: Installing in-line filters or lint

collectors will cause increased static pressure,

which will decrease tumbler efficiency and will void

machine warranty.

For maximum efficiency and minimum lint

accumulation, tumbler air must be exhausted to the

outdoors by the shortest possible route.

Proper sized exhaust ducts are essential for proper

operation. All elbows should be sweep type. Exhaust

ducts must be assembled so the interior surfaces are

smooth, so the joints do not permit the accumulation

of lint. DO NOT use plastic or thin foil flexible ducts.

Use exhaust ducts made of sheet metal or other

noncombustible material. Use duct tape or pop-rivets

on all seams and joints.

Verify that old ducts are thoroughly cleaned out before

installing new tumbler(s).

NOTE: Exhaust ducts must be constructed of sheet

metal or other noncombustible material. Such

ducts must be equivalent in strength and corrosion

resistance to ducts made of galvanized sheet steel

not less than 0.0195 inches (0.495 mm) thick.

Where the exhaust duct pierces a combustible wall or

ceiling, the opening must be sized per local codes. The

space around the duct may be sealed with noncombustible

material. Refer to Figure 15.

IMPORTANT: For best performance provide an

individual exhaust duct for each tumbler. Do not

install a hot water heater in a room containing

tumblers. It is better to have the water heater in a

separate room with a separate air inlet.

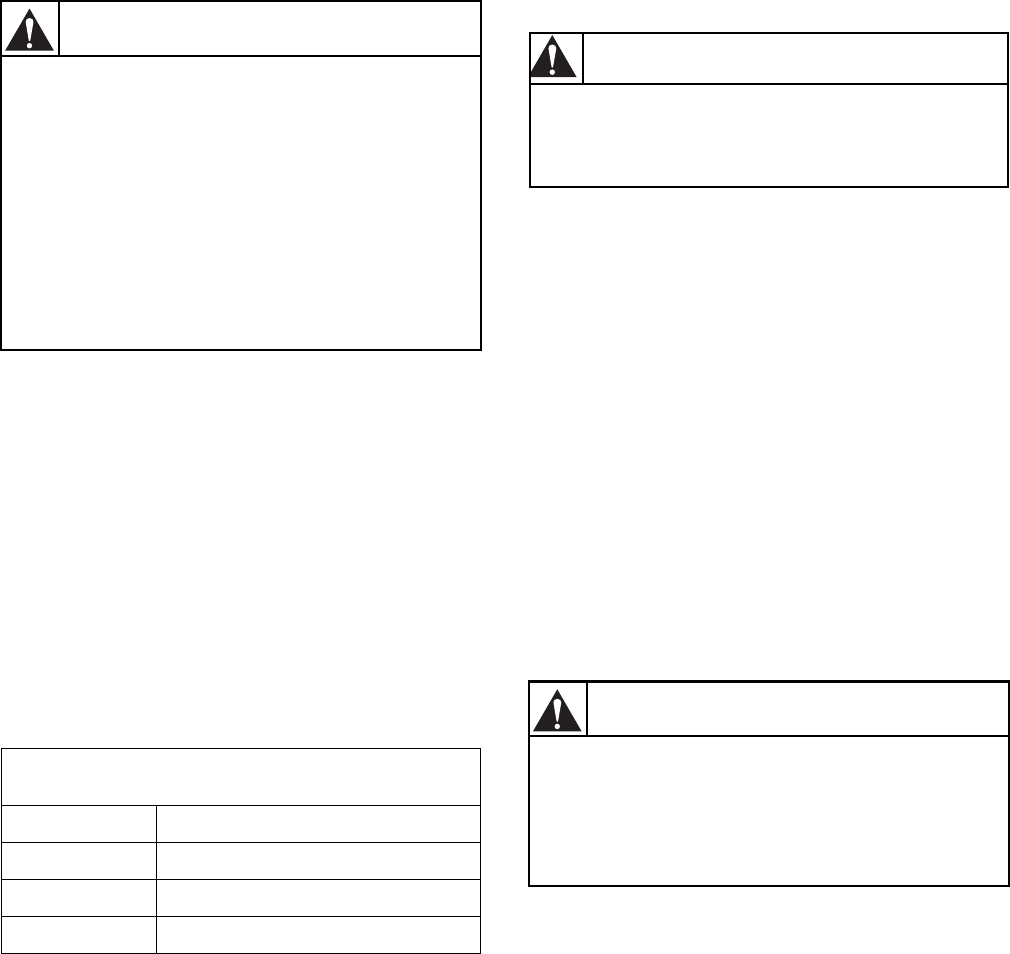

Required Make-Up Air Opening

(to the outside) for Each Tumbler

Model Opening

50 Pound

144 in

2

(928 cm

2

)

75 Pound

195 in

2

(1258 cm

2

)

F75

250 in

2

(1613 cm

2

)

WARNING

A drying tumbler produces combustible

lint. To reduce the risk of fire, the tumbler

must be exhausted to the outdoors.

W057

To reduce the risk of fire and

accumulation of combustible gases, DO

NOT exhaust tumbler air into a window

well, gas vent, chimney or enclosed,

unventilated area such as an attic wall,

ceiling, crawl space under a building, or

concealed space of a building.

W059

WARNING

To reduce the risk of fire due to increased

static pressure, do not install in-line

secondary lint filters or lint collectors.

W730

WARNING

Improperly sized or assembled ductwork

causes excess back pressure which

results in slow drying, lint collecting in

the duct, lint blowing back into the room,

and increased fire hazard.

W355