Exhaust Requirements

M414905

30

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Individual Venting

For maximum efficiency and performance, it is

preferred to exhaust tumbler(s) individually to the

outdoors.

IMPORTANT: At no point may the cross sectional

area of installed venting be less than the cross

sectional area of the exhaust outlet of the tumbler.

The exhaust duct must be designed so the static back

pressure measured 12 inches (305 mm) from the

exhaust outlet does not exceed the maximum

allowable pressure specified on the installation sticker

on the rear of the tumbler.

NOTE: Static back pressure must be measured

with the tumbler running.

The maximum allowable length venting is 14 feet (4.3 m)

and two 90° elbows or equivalent. If the equivalent

length of a duct required for an installation exceeds the

maximum allowable equivalent length, the diameter of

a round duct must be increased by 10% for each

additional 20 feet (6.1 m). Cross section area of a

rectangular duct must be increased by 20% for each

additional 20 feet (6.1 m). Refer to Table 2 to

determine equivalent venting.

Example: A 12 inch (305 mm) diameter duct’s

equivalent length of 14 feet (4.3 m) of duct and two

90° elbows is:

Equivalent Length = 14 feet + (2) 90° elbows

= 14 feet + 14 feet + 14 feet

= 42 feet (12.8 m)

With the tumbler in operation, airflow at any point

in the duct should be at least 1200 feet per minute

(366 m/min.) to ensure that lint remains airborne. If

1200 feet per minute cannot be maintained,

schedule monthly inspections and cleaning of the

ductwork.

Manifold Venting

While it is preferable to exhaust tumblers individually

to the outdoors, a main collector duct may be used if it

is sized according to Figure 16 and Figure 17. This

illustration indicates minimum diameters, and should

be increased if the collector length exceeds 14 feet (4.3

m) and two 90° elbows. The diameter of a round duct

must be increased by 10% for each additional 20 feet

(6.1 m). Cross sectional area of a rectangular or square

duct must be increased 20% for each additional 20 feet

(6.1 m). Refer to Table 3 and Table 4 tab to determine

equivalent ducting sizing. The collector duct may be

rectangular or square in cross section, as long as the

area is not reduced. Provisions MUST be made for lint

removal and cleaning of the collector duct.

The vent collector system must be designed so the

static back pressure measured 12 inches (305 mm)

from the exhaust outlet does not exceed the maximum

allowable pressure of 0.5 W.C.I. (1.3 mbar) as

specified on the installation sticker on the rear of

tumbler. Static back pressure must be measured with

all tumblers vented into the collector operating.

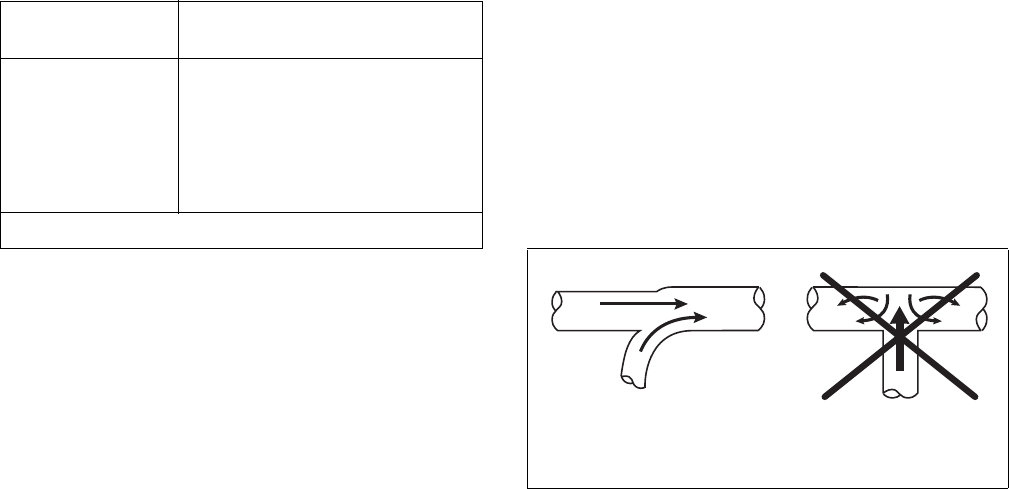

NOTE: Never connect a tumbler duct at a 90° angle

to the collector duct. Refer to Figure 14. Doing so

will cause excessive back pressure, resulting in poor

performance. Never connect two tumbler exhaust

ducts directly across from each other at the point of

entry to the collector duct.

With the tumbler in operation, airflow at any point

in the duct should be at least 1200 feet per minute

(366 m/min.) to ensure that lint remains airborne. If

1200 feet per minute cannot be maintained,

schedule monthly inspections and cleaning of the

ductwork.

Figure 14

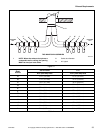

Duct

Diameter

Equivalent Length of

Straight Duct

8 in. (203 mm)

10 in. (254 mm)

12 in. (305 mm)

14 in. (356 mm)

16 in. (406 mm)

18 in. (457 mm)

One 90° elbow = 9.3 ft. (2.83 m)

One 90° elbow = 11.6 ft. (3.5 m)

One 90° elbow = 14 ft. (4.3 m)

One 90° elbow = 16 ft. (4.9 m)

One 90° elbow = 18.7 ft. (5.7 m)

One 90° elbow = 21 ft. (6.4 m)

Equivalent Length (feet) = 1.17 x Duct Diameter (inches)

Table 2

T438I

T438i