WARNI NG

!

Disassembly Procedures

To avoid risk of electrical shock, personal injury or death,

disconnect power to unit before servicing.

©2005 Maytag Services 16026502 29

6. Remove Pressure Switch hose, Tub Springs and

Outer Tub/Transmission assembly, see “Agitator/

Spinner/Outer Tub/Transmission Removal”

procedure steps 13, 14 and 16.

7. Remove screws from sides and rear of unit around

bottom, connecting Cabinet to Base. Remove

Cabinet from Base and set aside. Be sure to lay

down a protective pad before removing Tub and

Transmission assembly from Base. Remove Tub and

Transmission assembly, turn over and lay on

protective pad.

8. Remove Dust Cap, Retaining Ring, Washer, Cam,

and Drive Pulley from bottom of Transmission, see

“Drive Pully and Cam Removal” procedure.

9. Remove Brake assembly from Transmission, see

“Brake Disassembly” procedure steps 4 - 12.

Remove old Snubber from Transmission.

10.Install new Snubber, see “Snubber/Brake Assembly”

procedure steps 3 - 6. Insure Snubber is centered.

11.Turn new Base upside down and apply grease at

bottom of the spring hole pockets to eliminate noise

between Spring and Base interaction.

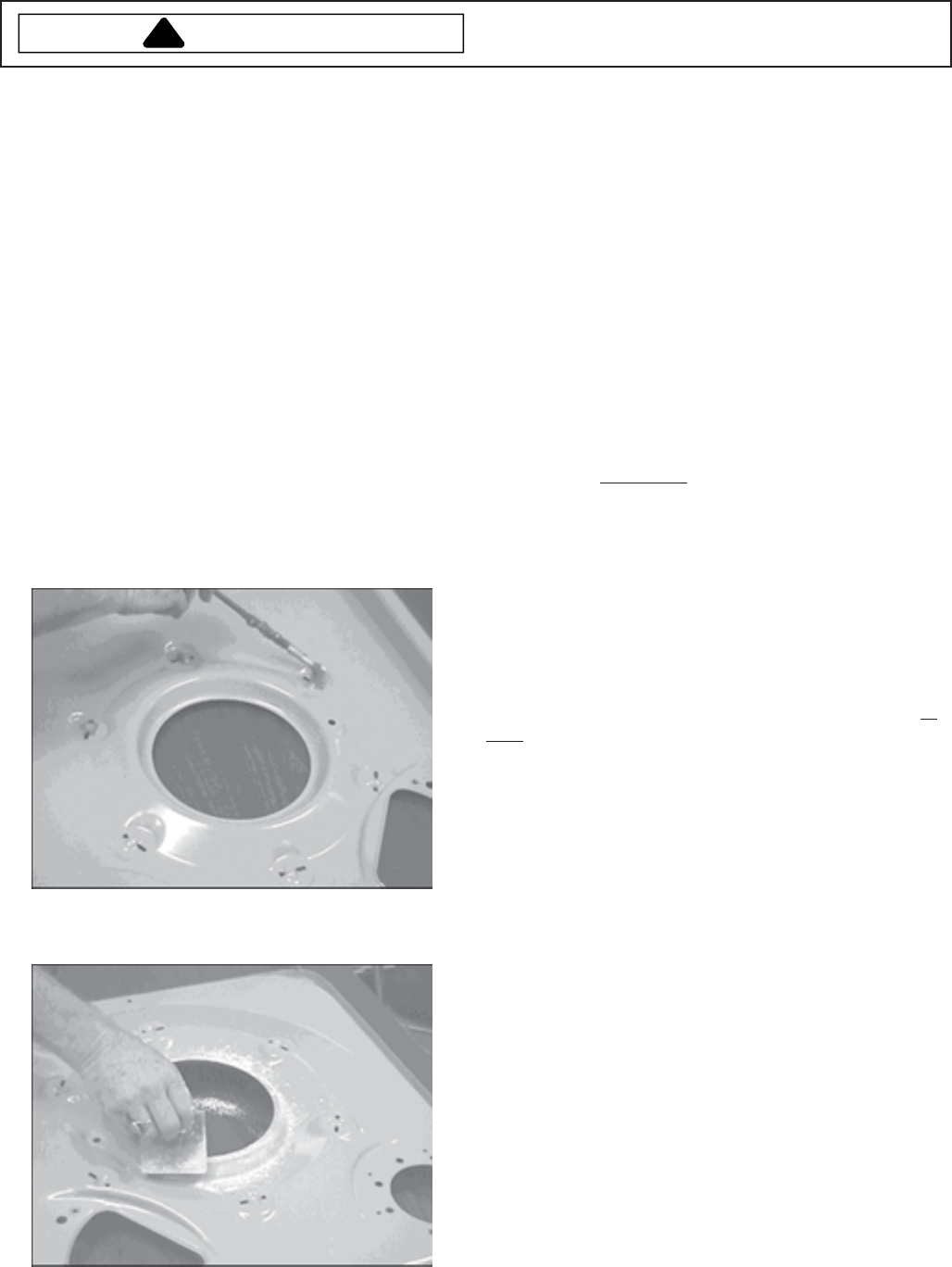

12.Clean the dome area of new Base with alcohol then

apply corn starch.

13.Reinstall Motor and Pump to new Base.

14.Transfer Transmission and Outer Tub onto new Base.

Attach Suspension Springs using spring tool to avoid

over stretching the Springs.

15.Transfer Cabinet shell onto new Base and

reassemble Washer. Be sure to reattach Pressure

Switch Hose to back of Tub, Drain Pump Hoses with

clamps to Drain Pump, and wire harness to Motor.

Check all hoses and wires to make sure they are

secure.

16.Test Washer.

Transmission Operation

When the Drive Pulley rotates CLOCKWISE, the upper

and lower cams are designed to nest together which

allows the Drive Pulley to remain in position on the drive

shaft. The Break remains engaged and the Drive Pulley

will turn the lower cam and drive the shaft to cause the

Transmission

to agitate.

When the Drive Pulley rotates COUNTERCLOCKWISE,

the upper cam and Pulley ride up the lower cam approxi-

mately 3/16 of an inch before the driving shoulders on the

Pulley hub engage the "dogs" on the lower cam.

This causes the top of the Pulley hub to push against the

Spacer which compresses the Brake Spring and lifts the

Brake Rotor and Lining assembly off the Brake Stator.

The Brake is disengaged and the Pulley will turn the

lower cam and drive shaft to cause the Transmission

to

spin.

Determine Brake Rotor Condition

Watch the Spacer on the Encapsulated Thrust Bearing.

If the Spacer rotates with the Pulley, the Brake is

functioning properly. If the Spacer stays stationary while

rotating the Pulley to release the Brake, the Brake Rotor

must be replaced.

After reassembling the Washer, fill the Tub with water

and select a spin to drain the Tub. When the cycle is

finished, verify the adjustment of the Brake, and verify

the Spacer on the Thrust Bearing rotates with the Pulley.

Brake Adjustment

1. After reassembling the components on the drive

shaft, it may be necessary to pull down on the shaft

to take the endplay out before the Thrust Washer

and Retaining Ring can be reinstalled.

NOTE: Each time the cams are reassembled on the

drive shaft, the point in the cam rise where the

Brake disengages the Stator should be checked

and adjusted as necessary. Reference points

have been molded into the Pulley as an aid in

checking the point of Brake disengagement.