22 INSTALLATION AND MAINTENANCE MANUAL PUBLICATION DATE 03/02 504 766

CONNECTION TO LIQUID SOAP SUPPLY SYSTEM

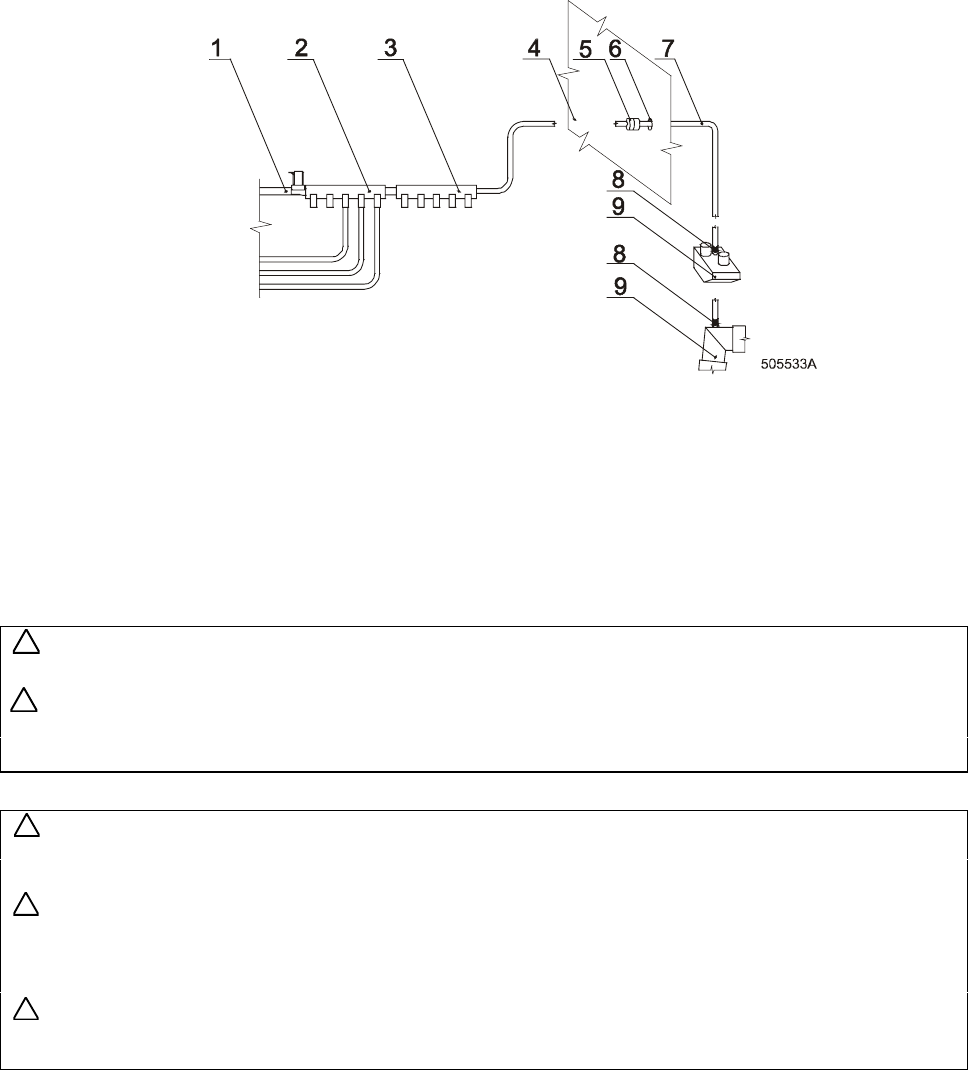

It is possible to connect external liquid soap supply system to the machine. Connect the hoses of liquid soap

supplies on inlets of dosing pumps. Connect outlets on vertical inlets of external liquid soap mixer (fig.4.4.E,

pos.2). After removing the black plug, put the hose of external liquid soap dosing (7), coming from the mixer,

through the hole in the machine rear side (6). Provide the opening, where the hose is coming through, with

rubber bushing (5). Connect the hose of liquid soap external dosing to the tube of mixer of water system (9)

inside the washing machine, and secure with the clamp (8). Mixer of the machine water system is accessible

after removing the rear or side cover. Connect the water supply (1) to inlet of electrical water valve, which is

connected to inlet of liquid soap external mixer. External mixer of liquid soap can be used for 1 - 5 supply

inlets of liquid soap. When you need to connect more supply inlets of liquid soap, use another mixer (3).

Connect the mixers in series.

1. Water supply

2. External mixer of liquid soap

3. Second external mixer of liquid soap

(extension)

4. Rear panel

5. Bushing

6. Hole for hose of external dosing (put through)

7. Hose of external dosing

8. Clamp

9. Mixer of the machine water system

Fig.4.4.E

CHECK IF THE HOSE IS TIGHTEN BY CLAMP!

ANY LEAKAGE OF CHEMICALS MAY CAUSE THE PARTS CORROSION INSIDE OF THE MACHINE.

WARNING !

PLACE EXTERNAL MIXER (MIXERS) NEAR THE MACHINE, NEVER INSIDE THE MACHINE.

WARNING !

ALWAYS INSTALL EXTERNAL MIXER (MIXERS) IN SUCH A WAY, SO THAT POSSIBLE ESCAPE

OF CHEMICALS COULD NOT CAUSE INJURY OF PERSONS OR DAMAGE OF PROPERTY.

WARNING !

DISCONNECT THE MACHINE POWER INLET BEFORE INSTALLATION.

THE INLET TERMINALS ARE UNDER CURRENT EVEN WHEN THE MAIN SWITCH IS OFF.

WARNING !

ELECTRICAL CONNECTION AND MACHINE INLETS MUST BE CARRIED OUT BY AUTHORIZED

WORKERS ACCORDING TO INSTALLATION MANUAL INSTRUCTIONS AND IN ACCORDANCE

WITH VALID LOCAL STANDARDS.

WARNING !

AFTER THE HOSE IS CONNECTED, PUT ALL MACHINE COVERS BACK TO THEIR PLACES

OTHERWISE YOU JEOPARDIZE INJURIES.

The liquid soap pump system supply needs to be connected to an external electrical source. Only authorised

workers with a valid qualification must execute the electrical connection of the machine according to the valid

local standards. Do not connect the pump system in the machine. The liquid soap signals are available in

the machine on a connector for connecting liquid soap pump. The last terminal is the common line of the signals.

The following terminals are the signals that will be active depending of the programmed wash programme.

These signals have a potential of max. 250V AC 50/60 Hz. Use a cable that is sufficcient for their function

!

!

!

33 kg / 80 lbs

40 kg / 100 lbs

55 kg / 125 lbs

22 kg / 50 lbs

!

!