13

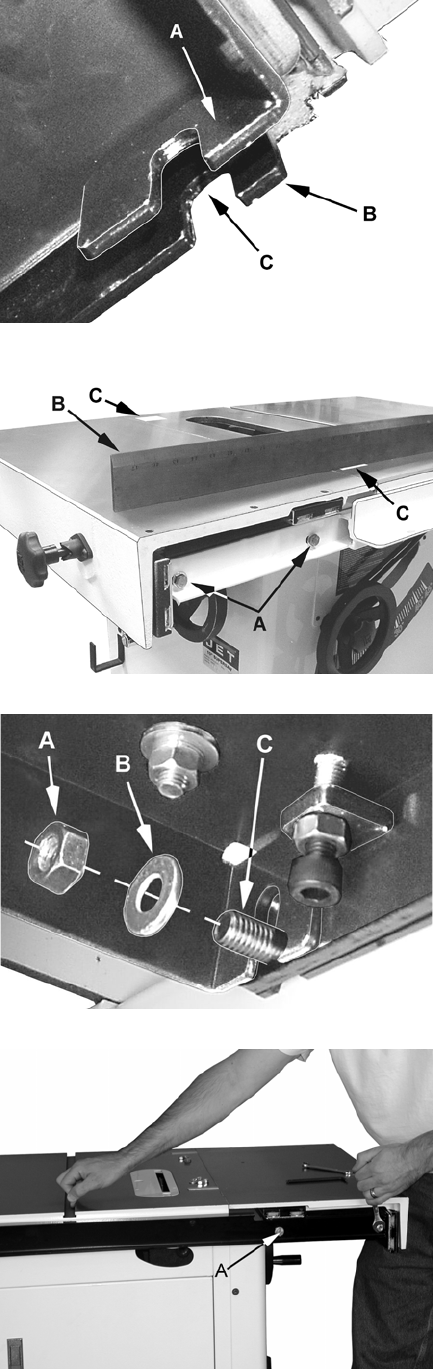

The support plate underneath the sliding table

(Figure 10) has an inner tab (A) and an outer

tab (B). When placing the table onto the

leveling bracket (D, Fig. 8), the leveling bracket

must be positioned between the inner and

outer tabs and the slots in the tabs (C, Fig. 10)

must straddle the screws (A, Fig. 8) that

secure the leveling bracket (D, Fig. 8) to the

rail (C, Fig. 8).

7. The sliding table should rest on the jacking

screws (G, Fig. 8).

8. Place two 90° 0.02” shims between the sliding

table and the table saw table near each end.

This will help keep the sliding table parallel to

the table saw table maintaining the proper

clearance.

9. Lower, or raise jacking screws (G, Fig. 8) so

that the sliding table surface is approximately

flush, or slightly lower than table saw table

surface.

10. Snug the four hex cap screws (A, Fig. 11) but

do not tighten. This will allow you to fine tune

the sliding table with the jacking screws.

11. Place a flat 0.02” shim (C, Fig. 11) on the table

saw tabletop for the straight edge (B, Fig. 11)

to rest on. This will help keep the sliding table

the right height above the top of the table saw.

12. Use two jacking screws (G, Fig. 8) to raise the

sliding table until it contacts the straight edge.

The straight edge should rest flat on sliding

table and shims.

13. Move straight edge to the other end of the

table saw tabletop and repeat step 12.

14. Tighten hex nuts (F, Fig. 8) against the leveling

bracket tabs while keeping jacking screws

(G, Fig. 8) from turning.

15. Tighten the four hex cap screws (A, Fig. 11)

that hold the leveling brackets in place.

Note: When tightening the screws on the rear

rail you may need to hold the sliding table

against the shims because there is a tendency

for the sliding table to move away from the

shim (Figure 12).

16. Verify that the jack screws (G, Fig. 8) contact

the sliding table support plate (Fig. 12).

17. Place M8 flat washers (A, Fig. 11A) and M8

hex nuts (B, Fig. 11A) on the four screws

(C, Fig. 11A). Using two 13mm wrenches,

tighten the hex nuts while holding the screw

heads.

18. Remove the shims and make sure the sliding

table is still approximately 0.02” higher than

the table saw tabletop; it is still approximately

0.02” away from the table saw tabletop.

Figure 10

Figure 11

Figure 11A

Figure 12