Installation

70269701

26

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

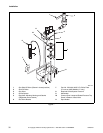

Installing CE Gas Drying Tumblers

General Information

This information is to be used when installing gas

tumblers in countries, and/or on gases, different than

the machine’s factory configuration. Tumblers are

supplied from the factory for operation on Natural Gas

1000 Btu/cu ft. (8914 kcal/m

3

), or L.P. Gas 2500 Btu/

cu ft. (22,250 kcal/m

3

) in the countries of GB/IE/PT/

ES/IT/GR/LU/CH. To install machines in any other

country, or on any other gas, requires some level of

modification.

Orifices, stickers, block-open kits, regulator springs

and other parts needed for conversions are to be

ordered separately.

Models are built in two different configurations:

● Regulated Natural Gas – Injector is sized for

Natural Gas, second family, group H (E) at

20 mbar inlet pressure. Regulator/governor is

operational. Gas valve CAN be field-converted to

a non-regulating type.

● Unregulated L.P. (Liquefied Petroleum) Gas –

Injector is sized for L.P., third family, group 3+ at

28.37 mbar inlet pressure. Regulator/governor is

blocked open. Gas valve CANNOT be field-

converted to a regulating type.

Serial plates supplied from the factory are configured

for the countries of GB/IE/PT/ES/IT/GR/LU/CH.

These instructions pertain to the situations when the

country of use or gas supply is different than that on

the serial plate.

Table 3 describes the different gases that are available

in different CE countries, and how the machines need

to be configured to operate with those gases. In the

CE, there are Natural Gases that do not allow for

machine regulation, and L.P. Gases that must be

regulated. For L.P. Gas, third family B/P at 50 mbar,

order regulated Natural Gas machines and convert

according to Table 3.

WARNING

To reduce the risk of electric shock, fire,

explosion, serious injury or death:

• Disconnect electric power to the

tumbler before servicing.

• Close gas shut-off valve to gas tumbler

before servicing.

• Close steam valve to steam tumbler

before servicing.

• Never start the tumbler with any guards/

panels removed.

• Whenever ground wires are removed

during servicing, these ground wires

must be reconnected to ensure that the

tumbler is properly grounded.

W002