Installation

70256801

22

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Basic Configuration

1. Determine the necessary conversion operations

to convert from the factory-supplied

configuration to the desired configuration.

2. Perform the conversions required so the machine

is properly configured for the desired country and

gas (refer to Specific Conversion Procedures

Section):

● How to Convert Gas Valve from Regulated to

Unregulated

NOTE: Conversion from regulated to unregulated

is only needed when regulated tumblers were

ordered, but unregulated tumblers were needed.

● How to Change Injector (Orifice) Size

● How to Adjust Gas Valve Governor/Regulator

3. If applicable, peel off the appropriate country

sticker from Part No. 503382 (included with

machine) and apply it to the serial plate over the

existing country information. Refer to

Figure 9.

4. If applicable, peel off the appropriate conversion

sticker from Part No. M413800 (included with

machine) and apply it to the serial plate over the

“ADJUSTED FOR ______ GAS: ______”

information. Refer to

Figure 9.

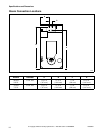

Figure 5

Specific Conversion Procedures

How to Convert Gas Valve from Regulated to

Unregulated

NOTE: Conversion from regulated to unregulated

is only needed when regulated tumblers were

ordered, but unregulated tumblers were needed.

Johnson G96 Gas Valve:

a. Disconnect electrical power from tumbler.

Close gas shut-off valve to tumbler. Refer to

Figure 5.

b. Follow instructions in Conversion Kit, Part

No. M400763 (Johnson Part No. Y71AA-5C).

NOTE: This kit does not contain any orifices.

c. Change injector size as required by the

appropriate table according to How to

Change Injector (Orifice) Size.

d. Commission tumbler for use.

WARNING

When converting the tumbler to a

different gas or pressure, first verify that

the supply inlet pressure is equipped with

a pressure regulator (located ahead of the

tumbler) that will maintain the gas supply

at the inlet pressure specified.

W430

T103K

1 Gas Shut-Off Valve (Ahead of pressure tap)

2 Pressure Tap

3 Gas Shut-Off Valve (Shown in closed

position)

SPECIFIED

LOCAL INLET

PRESSURE

3

2

1