14 American Dryer Corp. 113409-2

NOTE: As per the National Fuel Gas Code, “Exhaust ducts for Type 2 clothes dryers shall be constructed of

sheet metal or other noncombustible material. Such ducts shall be equivalent in strength and corrosion

resistance to ducts made of galvanized sheet steel not less than 26 gauge (0.0195-inches [0.5 mm])

thick.”

IMPORTANT: It is recommended that exhaust or booster fans not be used in the exhaust ductwork system.

Outside Ductwork Protection

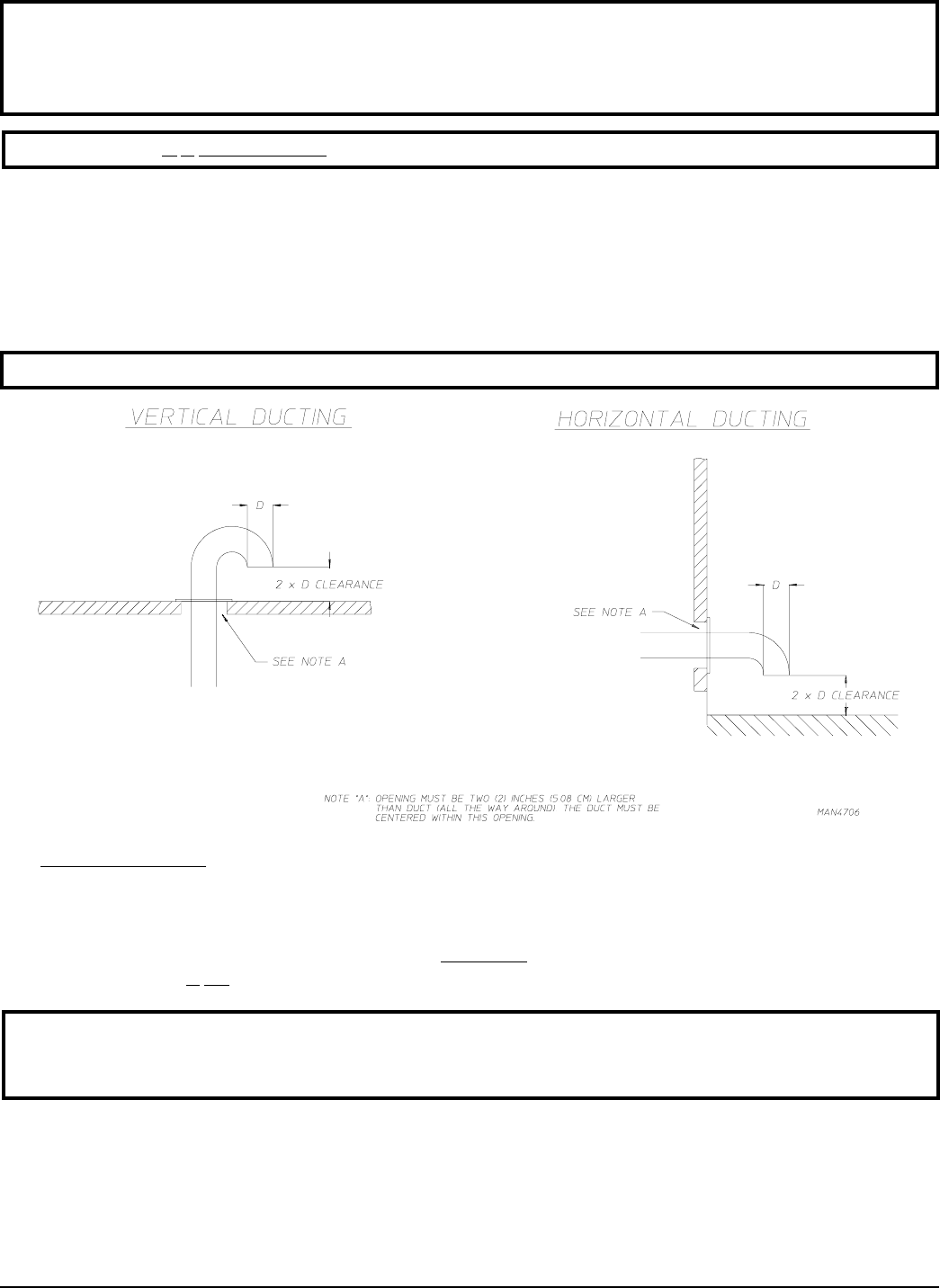

To protect the outside end of horizontal ductwork from the weather, a 90° elbow bent downward should be

installed where the exhaust exits the building. If the ductwork travels vertically up through the roof, it should be

protected from the weather by using a 180° turn to point the opening downward. In either case, allow at least twice

the diameter of the duct between the duct opening and the nearest obstruction.

IMPORTANT: DO NOT use screens, louvers, or caps on the outside opening of the exhaust ductwork.

2. Single Dryer Venting

Where possible, it is suggested to provide a separate exhaust duct for each dryer. The exhaust duct should be laid

out in such a way that the ductwork travels as directly as possible to the outdoors with as few turns as possible. It

is suggested that the use of 90° turns in the ducting be avoided; use 30° and/or 45° angles instead. The shape of the

exhaust ductwork is not critical as long as the minimum cross section area is provided.

IMPORTANT: The minimum duct size for a gas unit is 12-inches (30.48 cm) for a round duct and

12-inches x 10-inches (30.48 cm x 25.4 cm) for a square duct. THE DUCT SIZE MUST

NOT BE REDUCED ANYWHERE DOWNSTREAM OF THE DRYER.