Troubleshooting Procedures

!

WARNING

To avoid risk of electrical shock, personal injury, or death, disconnect power to washer before servicing, unless

testing requires it.

RS3100007 Rev. 0 13

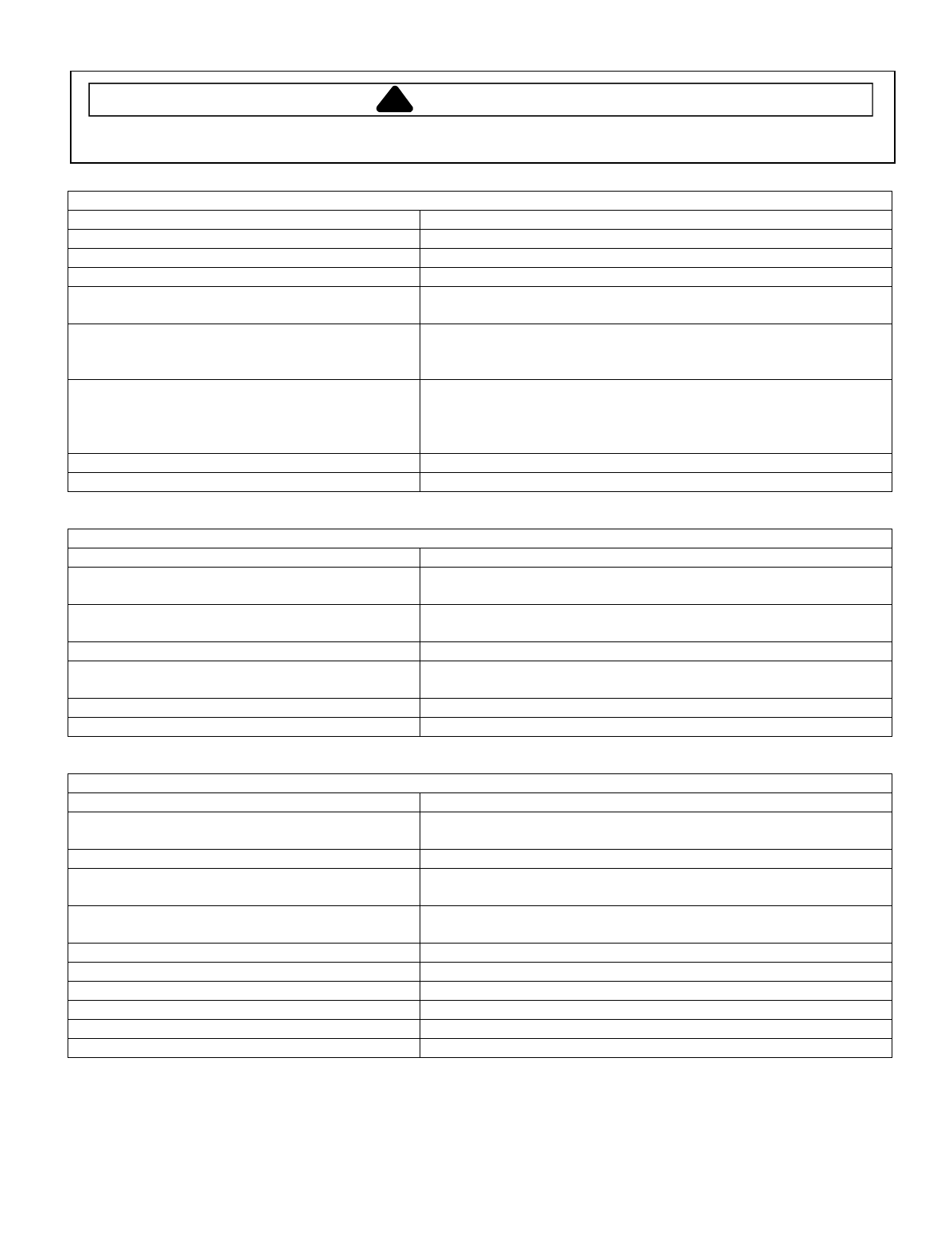

4. Water fill does not stop at proper level.

Possible Cause Result

Failed pressure switch. Test switch and replace if failed.

Air leak in pressure hose Replace pressure hose.

Water in pressure hose. Blow air through hose to remove water.

Broken, weak, or missing mixing valve

armature spring.

Replace mixing valve.

Sediment on or under mixing valve diaphragm,

failed diaphragm, or armature binding in

armature guide.

Replace mixing valve.

A siphoning action started in washer will cause

water to be siphoned from washer during cycle.

Caused by drain hose being lower than washer

cabinet top.

Install No. 526P3 Siphon Break Kit. Provide an air gap around

drain hose and drain receptacle. Install No. 36878 Standpipe

Adapter.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.

5. Timer does not advance.

Possible Cause Result

Timer is designed to pause during fill periods.

Some cycles have pause (delicate cycle).

Allow completion of fill period.

Loading door is open. Close loading door. Loading door MUST be closed anytime the

washer is set to agitate or spin.

Washer will not fill. Timer pauses until pressure switch is satisfied.

Verify washer is not siphoning during rinse

cycle.

Install No. 526P3 Siphon Break Kit.

Failed timer. Test timer and replace if failed.

Broken, loose, shorted, or incorrect wiring. Refer to appropriate wiring diagram.

6. Motor does not operate.

Possible Cause Result

Power cord not plugged in, blown fuse or

tripped circuit breaker at circuit panel.

Verify electrical power is present at outlet and unit is plugged in.

There is no internal fuse in the washer.

Loading door not closed or failed switch. Close door or test switch and replace if failed.

Motor overload protector has cycled. Wait two to three minutes for overload protector to reset. If

overload protector cycles repeatedly, see following chart.

Binding in upper or lower motor bearings. Remove belt and determine if motor shaft will spin. Replace

motor if shaft is locked up.

Motor is dead, electrical power is present. Test motor switch and windings.

Motor start functions fail or motor only hums. Test motor start switch and start windings.

Timer improperly set. Reset timer or try another cycle.

Failed timer. Test timer and replace if failed.

Failed electronic control. Test electronic control and replace if failed.

Broken, loose, shorted or incorrect wiring. Refer to appropriate wiring diagram.