© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Maintenance

F232201

28

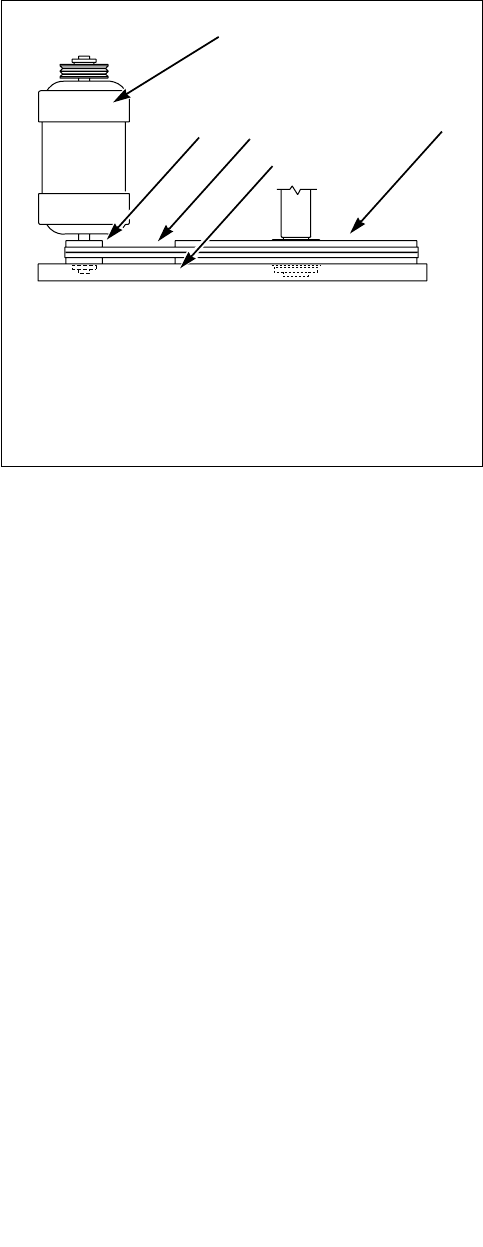

c. Verify that V-belts are properly aligned by

checking pulley alignment. Place a

straightedge across both pulley faces. The

straightedge should make contact with the

pulleys in four places. Refer to Figure 13.

Figure 13

3. Remove back panel and check overflow hose and

drain hose for leaks.

4. Unlock the hinged lid and check the supply

dispenser hoses and hose connections.

5. Clean inlet hose filter screens:

a. Turn water off and allow valve to cool, if

necessary.

b. Unscrew inlet hose and remove filter screen.

c. Clean with soapy water and reinstall. Replace

if worn or damaged.

6. Tighten motor mounting bolt locknuts and

bearing bolt locknuts, if necessary.

7. Use compressed air to clean lint from motor.

8. Clean interior of washer-extractor, both basket

and shell, by wiping with a water-soaked sponge

or cloth.

9. Use compressed air to ensure that all electrical

components are free of moisture and dust.

10. Remove chemical supply components and check

for residual chemicals. Clean as necessary and

replace.

Quarterly

NOTE: Disconnect power to the washer-extractor

before performing the quarterly maintenance

procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Tighten anchor bolts, if necessary.

3. Verify that the drain motor shield is in place and

secure.

4. Check all painted surfaces for bare metal.

(Matching gray paint is available from the

manufacturer.)

• If bare metal is showing, paint with primer or

solvent-based paint.

• If rust appears, remove it with sandpaper or

by chemical means.

Then paint with primer or solvent-based paint.

5. Clean steam filter, where applicable.

a. Turn off steam supply and allow time for the

valve to cool.

b. Unscrew nut.

c. Remove element and clean.

d. Replace element and nut.

P045I

1 Drive Motor

2 Drive Pulley

3 Belt

4 Straightedge

5 Driven Pulley

1

2

3

4

5