© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Operation

13

F232201

Theory of Operation

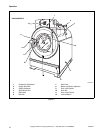

The design of the washer-extractor emphasizes

performance reliability and long service life. The

cylinder, shell, and main body panels are fabricated of

stainless steel.

Electrical controls for the washer-extractor are housed

in a separate enclosure located on the top of the

machine. Removing the screws from the module

cover, lifting the cover, and pulling to the rear

provides access to the control module. This module

contains the WE-6 control, contactors, water-level

switch, and other control components.

The cylinder is driven by a V-drive system supported

via the shaft by two flange-mounted spherical roller

bearings bolted to the A-frame.

The cylinder is constructed with four lifters or ribs that

lift the laundry from the bath solution when the

cylinder rotates at slow speed and then allow the

laundry to tumble back into the bath. This mechanical

action accomplishes the washing function. The

cylinder is perforated, allowing the water to drain from

within during the wash and extract steps.

The spray rinse feature consists of a fiber-reinforced

clear hose connected to the center of the door glass and

to both a hot and cold water inlet valve. A

hemispherically-shaped spray nozzle inside the door

glass produces a fan-action water spray which

disperses rinse water throughout the load.

All UWPV washer-extractors use an AC inverter drive

control which provides seven preset motor speeds

using a single motor. The AC drive interface board

converts motor logic from the WE-6 control to the

correct signals for the AC inverter drive. In addition,

all logic inputs to the control are routed through this

board.

The operator can select from among 39 preprogrammed

cycles. Cycle 39 is a test cycle used to verify proper

operation of the washer-extractor. With the exception

of Cycle 01, the remaining cycles are complete wash

cycles or specialty cycles designed to handle various

fabrics at specific water temperatures and levels.

Cycle 01 is designed to test an external chemical

injection supply system.

Programmable custom cycles are another feature of

the UWPV.

The vibration switch system utilizes a micro-switch

mounted between the faces of the A-frame to signal

the WE-6 control that the load imbalance is too great

for high extract speeds. Depending on the design

series, the vibration switch will perform in either of

two ways. If the washer-extractor utilizes ONLY the

vibration switch to detect an out-of-balance load, the

switch will signal the WE-6 control to slow the motor

speed, allowing the load to re-distribute, and then

resume the spin speed programmed. The control will

attempt to redistribute the load in this manner up to

three times. On the third attempt, if an imbalance

condition is still detected, the control will abort the

spin speed step(s) and advance to the next non-spin

speed step.

However, if the washer-extractor is equipped with

BOTH the vibration switch and the AC inverter drive

balance detection systems, the function of the switch is

slightly different. The inverter drive will monitor load

imbalance conditions and the control. If the load is not

balanced to spin at the programmed spin speed,

control will attempt to re-distribute the load. After

three unsuccessful attempts to balance the load,

control will limit the spin speed (on models with the

WE-6 Firmware ID Code of “ARWCxx” the WE-6

display will alternately flash the programmed spin

speed and the substituted spin speed). During the spin

step, if the vibration switch detects a severe imbalance,

due to improper installation or improper loading of the

washer, the control will abort the remaining portion of

the cycle and stop the machine. The display will flash

“BAL/DR” while aborting the cycle until the door has

been opened.

Water enters the washer-extractor through

electromechanical water valves controlled by the

microcomputer. The microcomputer also controls the

drain and the door lock. In addition, it selects the water

levels according to the programmed cycle. Vacuum

breakers are installed in the water-inlet plumbing to

prevent backflow of water.

The standard production UW35PV and UW60PV use

a single drain valve. (Dual drains are available as an

option.) The UW80PV, UW100PV, UW125PV and

UW150PV use dual drain valves. The dual drains open

and close together under control of the WE-6 control.

The drain valve is normally open, which means that it

closes only when power is applied, thus allowing the

machine to drain in the event of a power failure.

A door-lock system prevents opening of the stainless

steel door when a cycle is in progress. It also prevents

operation of the washer-extractor when the door is

open. The door box contains the door-lock

microswitch, door-closed magnetic switch, and the

door-unlock solenoid.

On later design models equipped with a rotation

sensor, the door lock system will allow door to unlock

soon after basket stops at the end of the cycle.