© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Maintenance

27

F232201

Monthly

NOTE: Disconnect power to the washer-extractor

at its source before performing the monthly

maintenance procedures.

1. Each month OR after every 200 hours of

operation, lubricate bearings. (Locate the bearing

lubrication decal at the rear of the right side of

the machine, as viewed from the front of the

washer-extractor.)

The grease must have the following

characteristics:

• NLGI Grade 2

• Lithium-based

• Water-insoluble

• Anti-rusting

• Anti-oxidizing

• Mechanically stable

The grease must have adequate base oil viscosity

with one of the following ratings:

• ISO VG 150 (135 – 165 cSt at 40°C or

709 – 871 SUS at 100°F)

• ISO VG 220 (198 – 242 cSt at 40°C or

1047 – 1283 SUS at 100°F)

• An SAE 40 rating is also acceptable as long as

the cSt or SUS values are within the specified

ranges.

Pump the grease gun slowly, permitting only

2strokes.

2. Use the following procedures to determine if

V-belts require replacement or adjustment. Call a

qualified service technician in either case.

a. Check V-belts for uneven wear and frayed

edges.

b. After disconnecting power to the washer-

extractor and removing all panels necessary

for access to the drive belt, use one of the

following methods to verify that V-belts are

properly tensioned.

• Tension Gauge. Loosen motor mounting

bolts and slide motor along motor plate to

change belt span length. The belt tension on

UW35 – UW125 models should be between

70 and 90 pounds (± 5 pounds). The belt

tension on the UW150 should be between

130 and 150 pounds (± 5 pounds). (Set initial

tension toward the high end of this range.)

The UW150 uses a swing mount motor with

an adjustable spring used for tensioning.

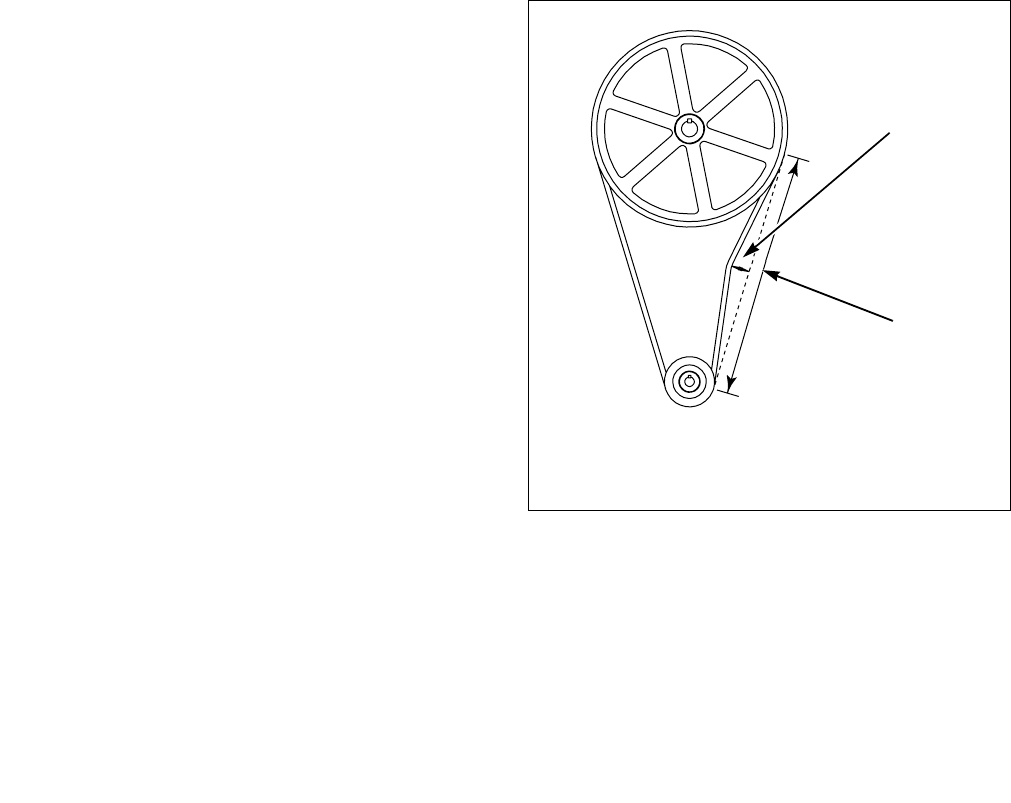

• Deflection. Refer to Figure 12. Loosen motor

mounting bolts and slide motor along motor

plate to change belt span length. Belt tension

measurements should be taken as close to the

center of the belt span as possible. For every

inch of span length, the belt should deflect

1/64 inch (0.40 mm). Thus, a belt with span

length of 50 inches should deflect 50/64 inch

(19.84 mm). An initial (run-in) force of

5.25 pounds should be used to set the belt

tension. An operating (normal) force of

3.5 pounds should be used after the washer-

extractor has been operated for a few hours.

Figure 12

P044I

1 Deflection

2 Span Length

1

2