6 American Dryer Corporation 450431-3

!

IMPORTANT: Make-up air must be provided from a

source free of dry cleaning fumes. Make-up air that is

contaminated by dry cleaning fumes will result in

irreparable damage to motors and other dryer

components.

Exhaust ductwork should be designed and installed by a

competent technician. Improperly sized ductwork will create

excessive back pressure, which will result in slow drying,

increased use of energy, and shut down of the burner by the

airflow (sail) switch, burner hi-limit or lint chamber hi-heat

protector thermostat. (Refer to appropriate Installation

Manual for more details.)

CAUTION: Improperly sized or installed

exhaust ductwork can create a potential fire

hazard.

Compressed Air Requirements

The dryer requires an external supply of air (2.5 cfm @ 80

psi [0.07 cmm @ 5.52 bar) on the steam models, the air is

necessary to operate the damper system. On both steam,

as well as the gas model, the air is necessary/required for

the blower air jet operation to clean lint from the impellor/

fan (squirrel cage type).

Electrical and Gas Requirements

It is your responsibility to have all electrical connections

made by a properly licensed and competent electrician to

assure that the electrical installation is adequate and

conforms to local and state regulations or codes. In the

absence of such codes, all electrical connections, materials,

and workmanship must conform to the applicable

requirements of the National Electrical Code ANSI/NFPA NO.

70-LATEST EDITION or in Canada, the Canadian Electrical

Codes Parts 1 & 2 CSA C22.1-1990 or LATEST EDITION.

IMPORTANT: Failure to comply with these codes or

ordinances and/or the requirements stipulated in this

manual can result in personal injury or component failure.

The dryer installation must meet the American National

Standard, National Fuel Gas Code ANSI Z223.1-LATEST

EDITION, or in Canada, the Canadian Electrical Codes Parts

1 & 2 CSA C22.1-1990 or LATEST EDITION (for Electrical

Connections) as well as, local codes and ordinances, and

must be done by a qualified technician.

NOTE: Undersized gas piping will result in ignition

problems and slow drying and can create a safety hazard.

The dryer must be connected to the type of gas (natural or

L.P.) indicated on the dryer data label. If this information

does not agree with the type of gas available, contact the

reseller who sold the dryer or contact the factory.

The gas input ratings shown on the dryer data label are for

elevations up to 2,000 feet (610 meters), unless elevation

requirements of over 2,000 feet (610 meters) were specified

at the time the dryer order was placed with the factory. The

adjustment for dryers in the field for elevations over 2,000

feet (610 meters) are made by changing the burner orifices.

If this adjustment is necessary, contact the reseller who

sold the dryer or contact the factory.

NOTE: Any burner changes must be made by a qualified

technician.

Operational Service Check Procedure

Turn on electric power to the dryer.

To start dryer:

Display will read “READY.”

Press “E” on the keypad of microprocessor controller

(computer).

The dryer will start to run.

NOTE: Pressing keypad “A,” “B,” “C,” “D,” or “F” will also

start the dryer. Six preprogrammed drying cycles (“A”

through “F”) have been stored in the computer’s memory.

(Refer to Computer Operator’s Manual for details.)

Make a complete operational check of all the operating

controls to assure that the timing is correct, temperature

selection switches are functioning, etc.

Make a complete operational check of all safety-related

circuits: door switch(es), hi-limit thermostat, sail switch,

cycling thermostats, etc.

For gas dryers, a gas pressure test should be taken at the

gas valve pressure tap of each dryer to assure that the water

column pressure is correct and consistent.

NOTE: Water column pressure requirements (measured

at the pressure tap on the gas valve body):

Natural Gas – 3.5 in wc; L.P. Gas – 10.5 in wc

If computer program changes are required, refer to the

Phase 6 OPL Operator’s Manual (ADC P/N 113022) for

details.

The dryer should be operated through one complete cycle

to assure that no further adjustments are necessary and

that all components are functioning properly.

Check the electric service phase sequence. While the dryer

is operating, check to see if the tumbler is rotating in the

proper direction. Looking from the front, the tumbler should

spin in the clockwise direction. If so, the phasing is correct.

If the phasing is incorrect, reverse two leads at connections

L1, L2, or L3 of power supply to the dryer.

Description of Parts __________________

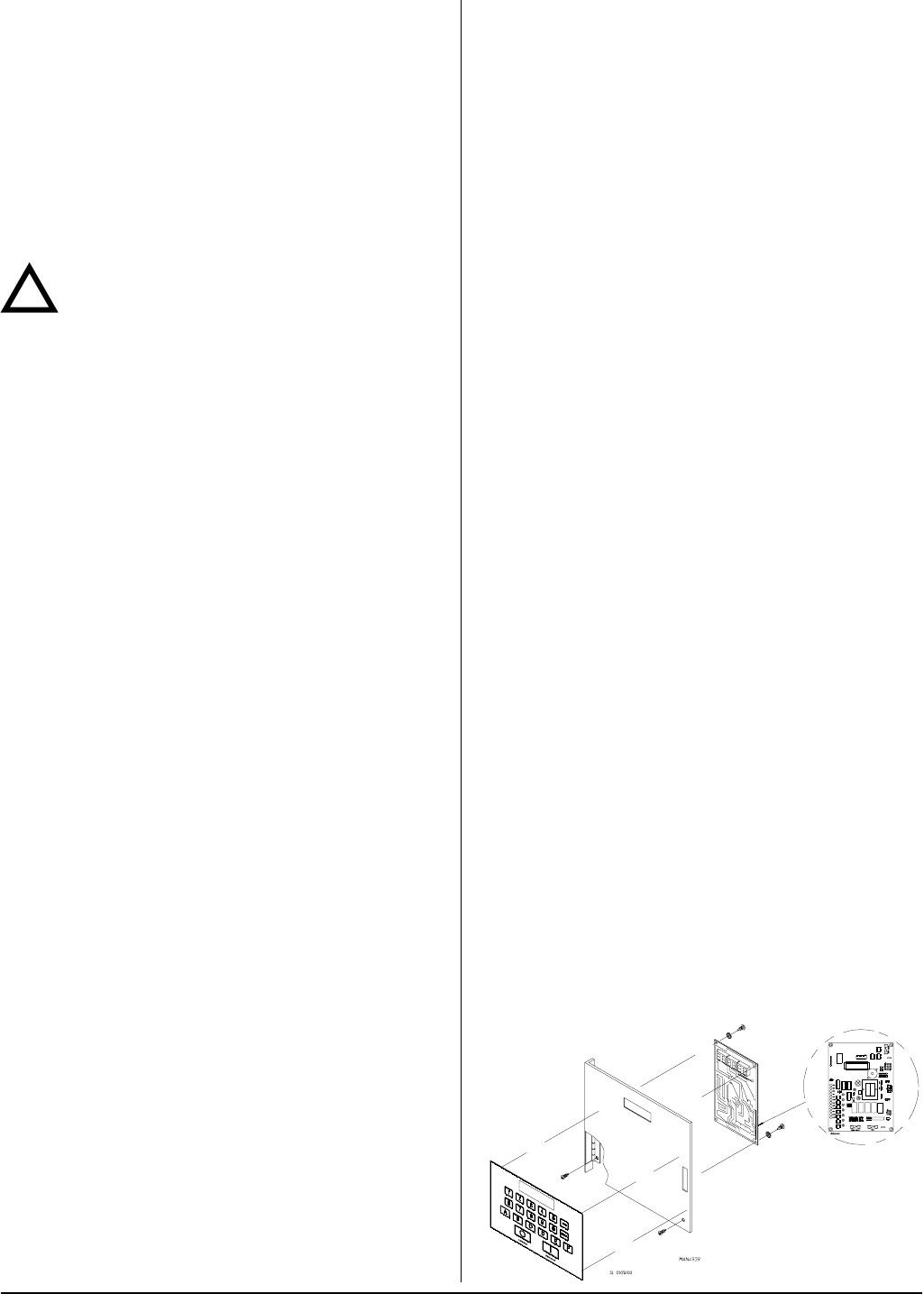

Control Panel (Microprocessor)

Opening the control panel will allow access to the major

components, which include the computer board and keypad.

The keypad inputs to the computer what temperature and

program has been selected. The computer controls the

entire operation of the machine. It accepts inputs and gives

outputs to various parts throughout the machine.