Electrical Wiring

The electrical installation should be in accordance with

National Electrical Code, local codes and regulations. Proper

overcurrent protection should be provided for the fan motors.

Wiring diagrams shown are only basic and do not show

fuses, disconnect switches, etc., which must be provided in

the eld.

All standard motors have internal inherent overload protectors.

Contactors can be used instead of starters requiring thermal

protectors, eliminating the problem of furnishing the proper

heating elements.

All air-cooled condensers are furnished with either single-

phase or three-phase fan motors, identied by the unit data

plate. Three-phase motors must be connected to three-phase

power voltage to agree with motor and unit data plate.

The motors must be checked for proper rotation. Be sure

to check that motor voltage and control connection agree

with electric services furnished. The motors are wired into

a common junction box. Where fan cycling is furnished and

factory installed, the motors are completely wired through the

control and to the contactors.

Electrical leads from each motor terminate at the unit junction

box. Field connections must be made from these leads through

a contactor, fuse and disconnect in accordance with local, state

and national codes.

6 Part # 2500018

Installation and Operations Manual

Line Size

(Type L

Copper

OD)

Drain Line

Velocity 100 FPM Refrigerant

R-22

R-404A/

R-507

R-410A

1/2 2.30 1.50 2.00

5/8 3.70 2.30 3.20

7/8 7.80 4.90 6.70

1-1/8 13.20 8.30 11.40

1-3/8 20.20 12.60 17.40

1-5/8 28.50 17.90 24.60

2-1/8 49.60 31.10 42.60

2-5/8 76.50 48.00 66.00

3-1/8 109.20 68.40 94.20

3-5/8 147.80 92.60 127.40

4-1/8 192.10 120.30 165.70

Temp.

Discharge Line

R-22

R-404A/

R-507

R-410A

90 0.88 0.92 0.89

100 0.95 0.97 0.96

110 1.04 1.01 1.03

120 1.10 1.03 1.10

130 1.18 1.04 1.16

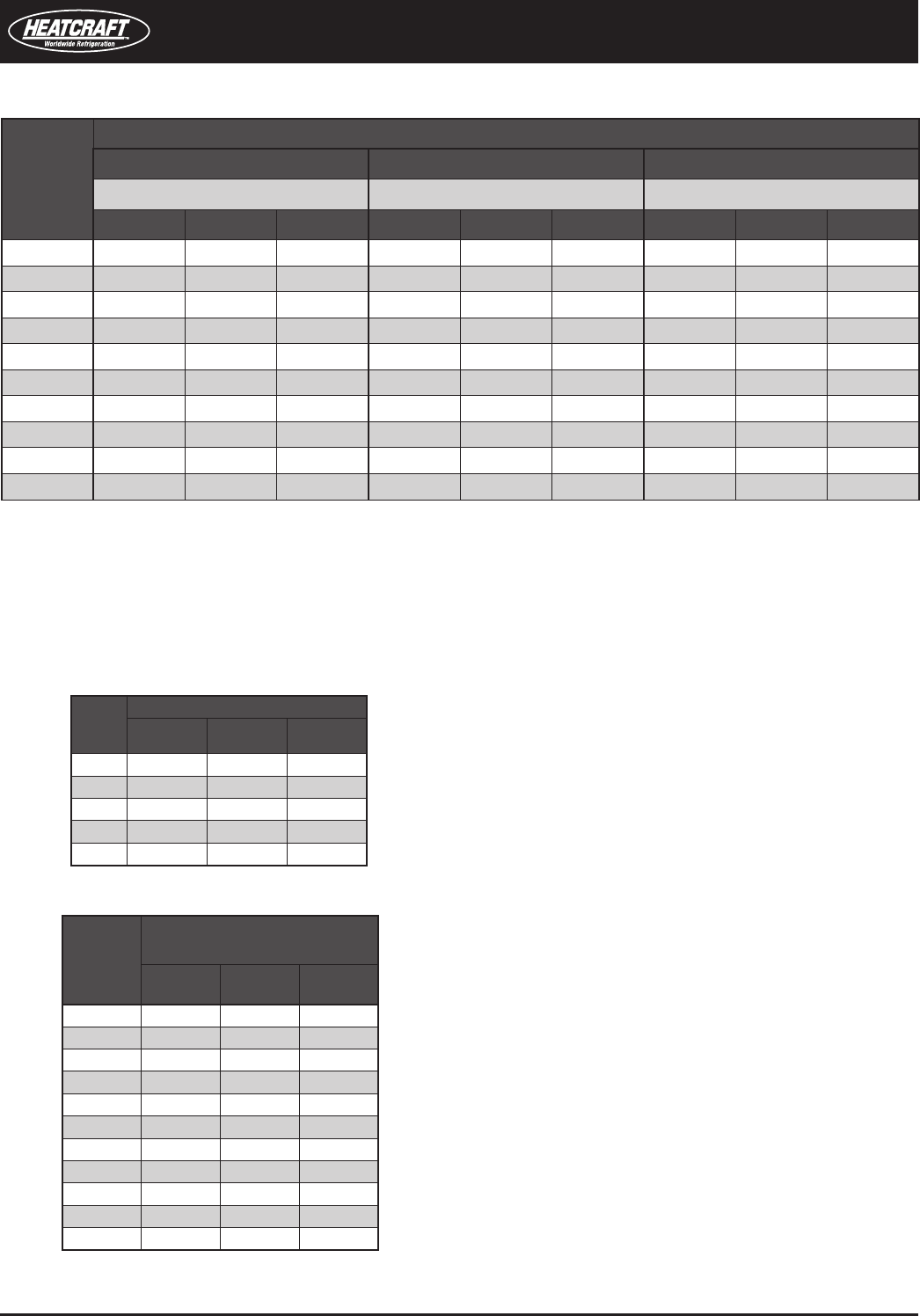

Table 3� Tons of Refrigeration, Drain

Table 2� Condensing Temperature Correction Factor

Line Size

(Type L

Copper OD)

Discharge Line

R-22 R-404A/R-507 R-410A

Sat. Suction Temp (°F) Sat. Suction Temp (°F) Sat. Suction Temp (°F)

-40 0 40 -40 0 40 -40 0 40

1/2 0.75 0.80 0.85 0.61 0.70 0.79 1.17 1.26 1.33

5/8 1.40 1.50 1.60 1.14 1.31 1.48 2.20 2.36 2.49

7/8 3.70 4.00 4.20 2.98 3.44 3.87 5.76 6.12 6.52

1-1/8 7.50 8.00 8.50 6.01 6.96 7.81 11.64 12.50 13.17

1-3/8 13.10 14.00 14.80 10.46 12.10 13.58 20.21 21.72 22.88

1-5/8 20.70 22.00 23.40 16.49 19.07 21.41 31.92 34.30 36.14

2-1/8 42.80 45.70 48.50 34.08 39.43 44.26 65.88 70.78 74.57

2-5/8 75.40 80.40 85.40 59.95 69.36 77.85 115.90 124.53 131.20

3-1/8 120.20 128.20 136.20 95.48 110.47 124.00 184.62 198.36 208.98

3-5/8 178.40 190.30 202.10 141.46 163.67 183.71 273.54 293.90 309.69

Table 1� Tons of Refrigeration, Discharge

Source: ASHRAE Refrigeration Handbook.

Line sizes based on pressure drop equivalent to 1°F per 100 equivalent feet.

Values in table are based on 105°F condensing temperature. Multiply table capacities by the factors in Table 2 for other condensing temperatures.

If subcooling is substantial or the line is short, a smaller line size may be used. Applications with very little subcooling or very long lines may require

larger sizes.

1.

2.

3.

Tables 1, 2 and 3 provide recommendations for discharge and liquid drain line sizes for

remote condenser selections.