113610-1 www.amdry.com 15

!

Piping/Connections

All components/materials must conform to National Fuel Gas

Code Specifications ANSI Z223.1-LATEST EDITION, or in

Canada, CAN/CGA-B149.1-M91 (Natural Gas) or CAN/CGA-

B149.2-M91 (L.P. Gas) or LATEST EDITION (for General

Installation and Gas Plumbing), as well as local codes and

ordinances and must be done by a qualified professional. It

is important that gas pressure regulators meet applicable

pressure requirements, and that gas meters be rated for the

total amount of all the appliance Btu being supplied.

The dryer is provided with a 1/2” N.P.T. inlet pipe connection

located at the upper left rear of the dryer. The minimum pipe

size (supply line) to the dryer is 1/2” diameter. For ease in

servicing, the gas supply line of each dryer must have its

own shutoff valve.

The size of the main gas supply line (header) will vary

depending on the distance this line travels from the gas

meter or, in the case of L.P. gas, the supply tank, other gas-

operated appliances on the same line, etc. Specific

information regarding supply line size should be determined

by the gas supplier.

Note

Undersized gas supply piping can create a low or

inconsistent pressure, which will result in erratic

operation of the burner ignition system.

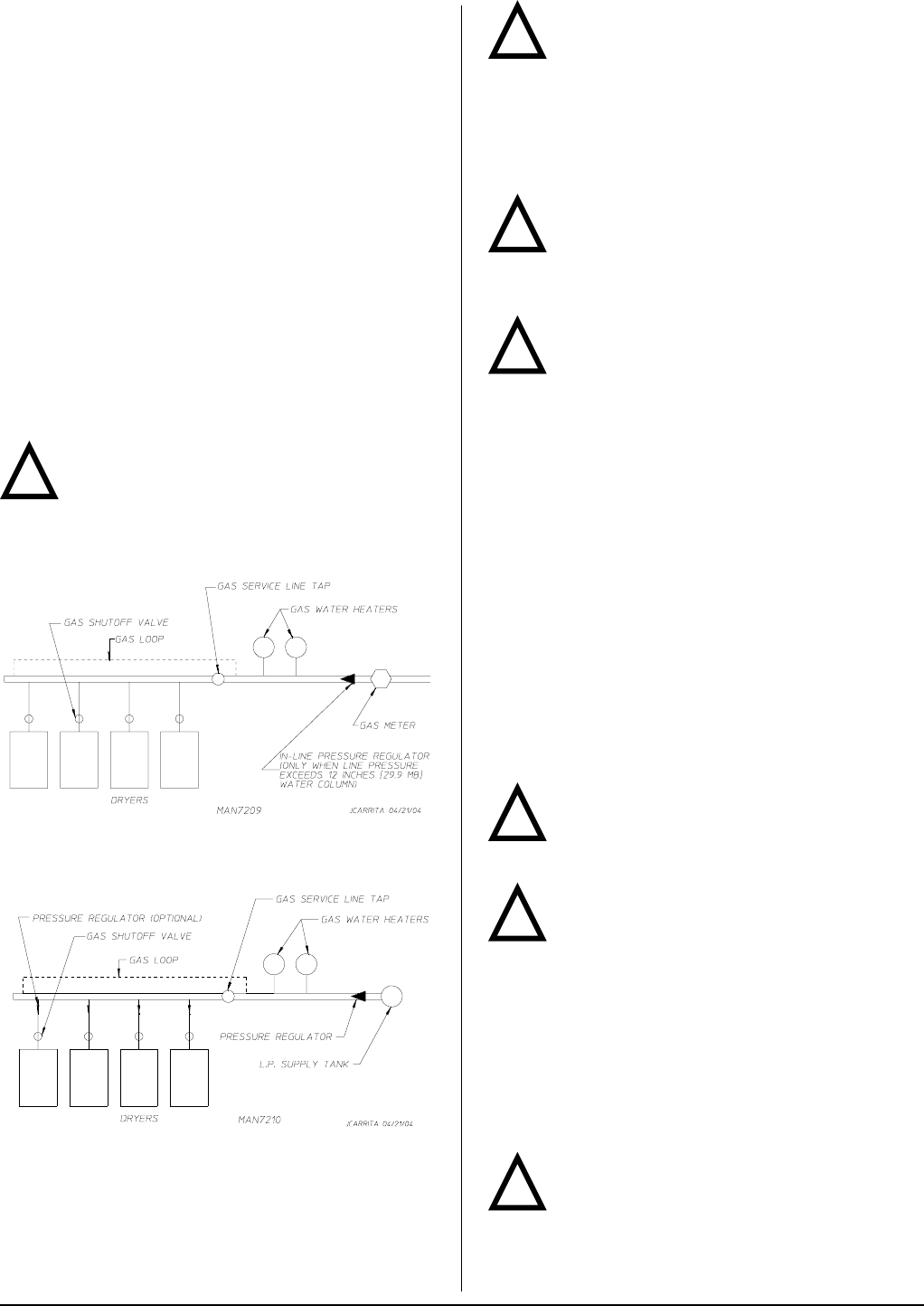

Typical Natural Gas Installation

Typical L.P. Gas Installation

!

!

!

Note

A water column test pressure of 3.5 in WC (8.7

mb) for natural gas and 10.5 in WC (26.1 mb) for

L.P. dryers is required at the gas valve pressure tap of

each dryer for proper and safe operation.

A 1/8” N.P.T. plugged tap, accessible for a test gauge

connection, must be installed in the main gas supply line

immediately upstream of each dryer.

Important

Pipe joint compounds that resist the action of

natural gas and L.P. gas must be used.

Test all connections for leaks by brushing on a soapy

water solution (liquid detergent works well).

Warning

Never test for leaks with a flame!!!

Steam Information ___________________

It is your responsibility to have all plumbing connections made

by a qualified professional to ensure that the steam plumbing

installation is adequate and conforms with local and state

regulations or codes.

Care must be exercised when leveling steam dryers into

final position. After leveling the dryer, check the downward

pitch of the heat exchanger from front to rear with a level.

Likewise, check the downward pitch of the return condensate

manifold toward its outlet part. Absence of these downward

pitches will result in probable water hammer and premature

heat exchanger fracture and leakage.

The presence of condensate in the steam will cause water

hammer and subsequent heat exchanger failure. The steam

supply connection must be taken from the top of a

well-dripped steam main. If the supply run-out to the dryer

exceeds 20 feet (6.096 meters), it should be dripped just

before the control valve with a proper trap and dirt pocket.

Important

Failure to comply with the requirements

stipulated in this manual can result in component

failure, which will void the warranty.

Note

The dryer is manufactured with a pneumatic

(piston) damper system, which requires an

external air supply of 0.75 cfh @ 80 psi +/- 10 psi (0.02

cmh @ 5.51 bar +/- 0.69 bar).

Steam Coil pH Level

The normal pH level for copper type steam coils must be

maintained between a value of 8.5 to 9.5. For steel type

steam coils the pH level must be maintained between a

value of 9.5 to 10.5. These limits are set to limit the acid

attack of the steam coils.

Impor tant

Coil failure due to improper pH level will void the

warranty.

!

!

!

Consistent gas pressure is essential at all gas connections.

It is recommended that a 3/4-inch (19.05 mm) pipe gas loop

be installed in the supply line servicing a bank of dryers. An

in-line pressure regulator must be installed in the gas supply

line (header) if the (natural) gas pressure exceeds 12.0 in

WC (29.9 mb) pressure.