22

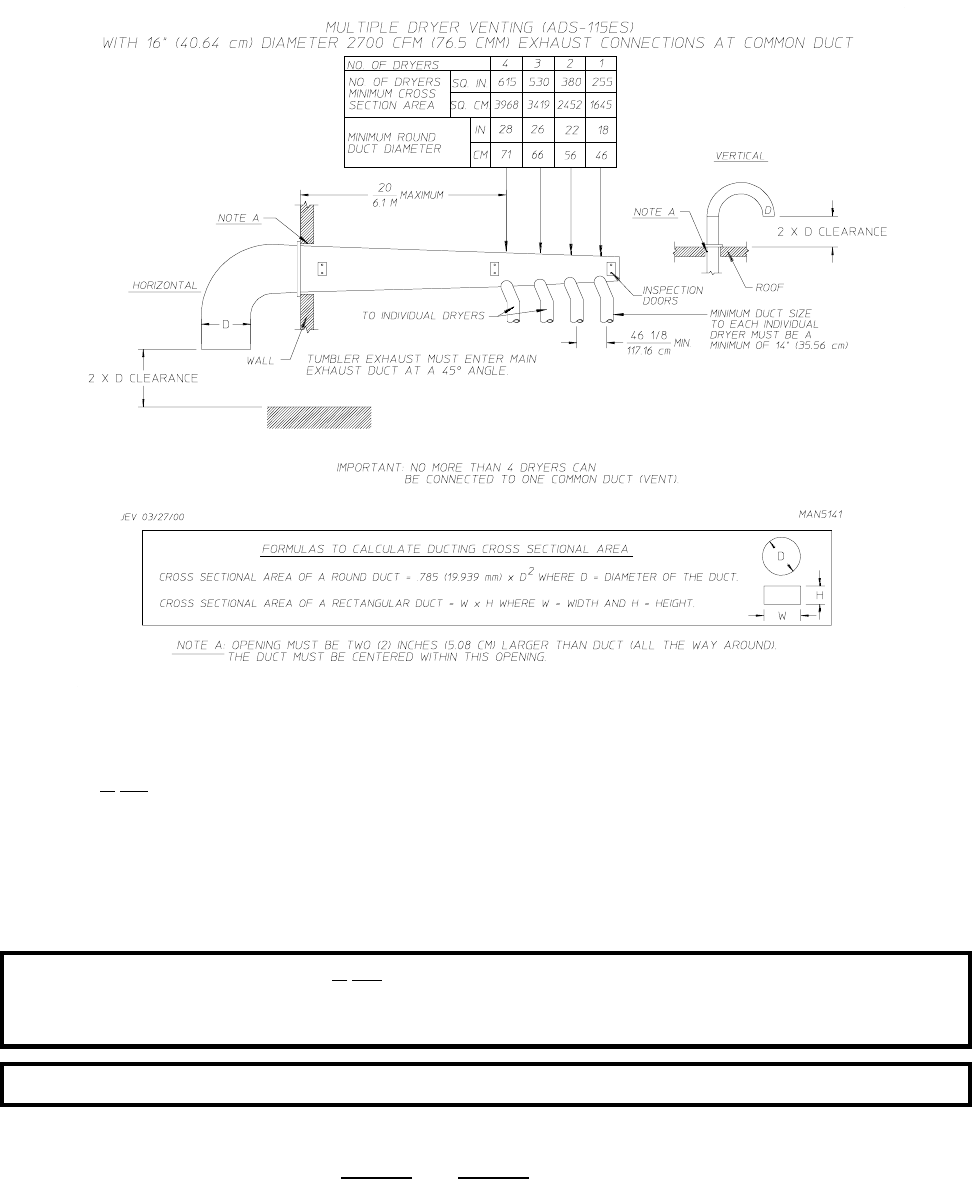

c. Vertical Venting

If it

is not feasible to provide separate exhaust ducts for each dryer, ducts from individual dryers may be

channeled into a "common main duct." The individual ducts should enter the bottom or side of the main

duct at an angle not more than 45° in the direction of air flow and should be spaced at least 46-1/8"

(117.16 cm) apart. The main duct should be tapered, with the diameter increasing before each individual

14-inch - 35.56 cm - (minimum for gas dryers or 60 Kw/72 Kw electric dryers) or 16-inch - 40.64 cm -

(minimum 80 Kw electric dryers or steam dryers) duct is added.

IMPORTANT: The AD-115ES is not provided with a back draft damper. When exhausted into a

multiple (common) exhaust line, a back draft damper must be installed at each dryer

duct.

IMPORTANT: No more than three (3) dryers should be connected to one main common duct.

The main duct may be any shape or cross sectional area, so long as the minimum cross section area is

provided. The illustrations on page 24 and page 25 show the minimum cross section area for multiple

dryer round or square venting. These figures must be increased 10 square inches (64.52 square centi-

meters) when rectangular main ducting is used, and the ratio of duct width to depth should not be greater

than 3-1/2 to 1. These figures must be increased in proportion if the main duct run to the last dryer to

where it exhausts to the outdoors is unusually long (over 20 feet [6.1 meters]) or has numerous elbows

(more than one [1]) in it. In calculating duct work size, the cross section area of a square or rectangular

duct must be increased twenty-percent (20%) for each additional 20 feet (6.1 meters). The diameter of

a round exhaust must be increased ten-percent (10%) for each additional 20 feet (6.1 meters). Each 90°

elbow is equivalent to an additional 30 feet (9.14 meters) and each 45° elbow is equivalent to an additional

15 feet (4.57 meters).