© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

M414545

45

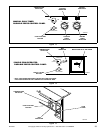

CHAIN DRIVE

Nonreversing Models

Refer to Figure 20.

Proper tension is when the belt can be depressed

approximately 1/2 inch (1.27 cm) by applying light

thumb pressure at a point midway between the cylinder

sprocket and the idler sprocket.

IMPORTANT: After a tumbler has been in operation

over an extended period of time, a “HIGH POINT”

will develop on the cylinder drive sprocket through

use and wear. Turn the sprocket manually with drive

chain in place until this “high point” is at the top

center. The “high point” can be found by noticing

increased chain tension while slowly rotating the

cylinder sprocket manually.

1. Remove guard from rear of tumbler.

2. To adjust chain tension, loosen acorn nut holding

idler sprocket to housing.

3. Move idler sprocket left or right until proper chain

tension is reached, then retighten the acorn nut.

4. Replace the guard on rear of tumbler.

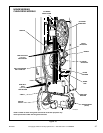

BELT DRIVE

Nonreversing Models

Refer to Figure 21.

Proper tension is when the drive V-belt can be depressed

approximately 1/2 inch (1.27 cm) by applying light

thumb pressure at a point midway between the sheave

and motor pulley.

1. Remove guard from rear of tumbler.

2. To adjust belt tension, loosen idler housing bolts

holding idler housing assembly to the housing

support.

3. Position housing assembly by turning adjusting bolt

until proper belt tension is reached, then retighten

idler housing bolts.

4. Replace the guard on rear of tumbler.

To reduce the risk of electric shock, fire, explosion, serious injury or death:

• Disconnect electric power to the tumbler before servicing.

• Close gas shut-off valve to gas tumbler before servicing.

• Close steam valve to steam tumbler before servicing.

• Never start the tumbler with any guards/panels removed.

• Whenever ground wires are removed during servicing, these ground wires must be reconnected

to ensure that the tumbler is properly grounded.

W002

WARNING