© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

M414545

17

Section III

Installation Instructions

RECEIVING INSPECTION

Upon delivery, visually inspect crate carton and parts for

any visible shipping damage. If the crate, carton or cover

are damaged or signs of possible damage are evident,

have the carrier note the condition on the shipping papers

before the shipping receipt is signed, or advise the carrier

of the condition as soon as it is discovered.

Remove the crate and protective cover as soon as possible

and check the items listed on the packing list. Advise the

carrier of any damaged or missing articles as soon as

possible. A written claim should be filed with the carrier

immediately if articles are damaged or missing.

IMPORTANT: Remove the shipping tape from the

two back draft dampers located in the exhaust

thimble.

MATERIALS REQUIRED

(Obtain Locally)

GAS, ELECTRIC OR STEAM DRYING

TUMBLERS

• One fused disconnect switch or circuit breaker.

GAS DRYING TUMBLERS ONLY

• One gas shut-off valve for gas service line to each

tumbler.

STEAM DRYING TUMBLERS ONLY

• One steam shut-off valve for steam service line to be

connected upstream of solenoid steam valve.

• Two steam shut-off valves for each condensate return

line.

• Flexible steam hoses with a 125 psig (pounds per

square inch gauge) (8.79 kg/sq. cm) working pressure

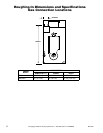

for connecting steam coils. Refer to Figure 9 and

Table 3.

• Two steam traps for steam coil outlet to condensate

return line.

• Two vacuum breakers for condensate return lines.