© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

26 M414545

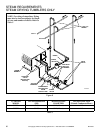

Example of Gas Loop Piping

Figure 7

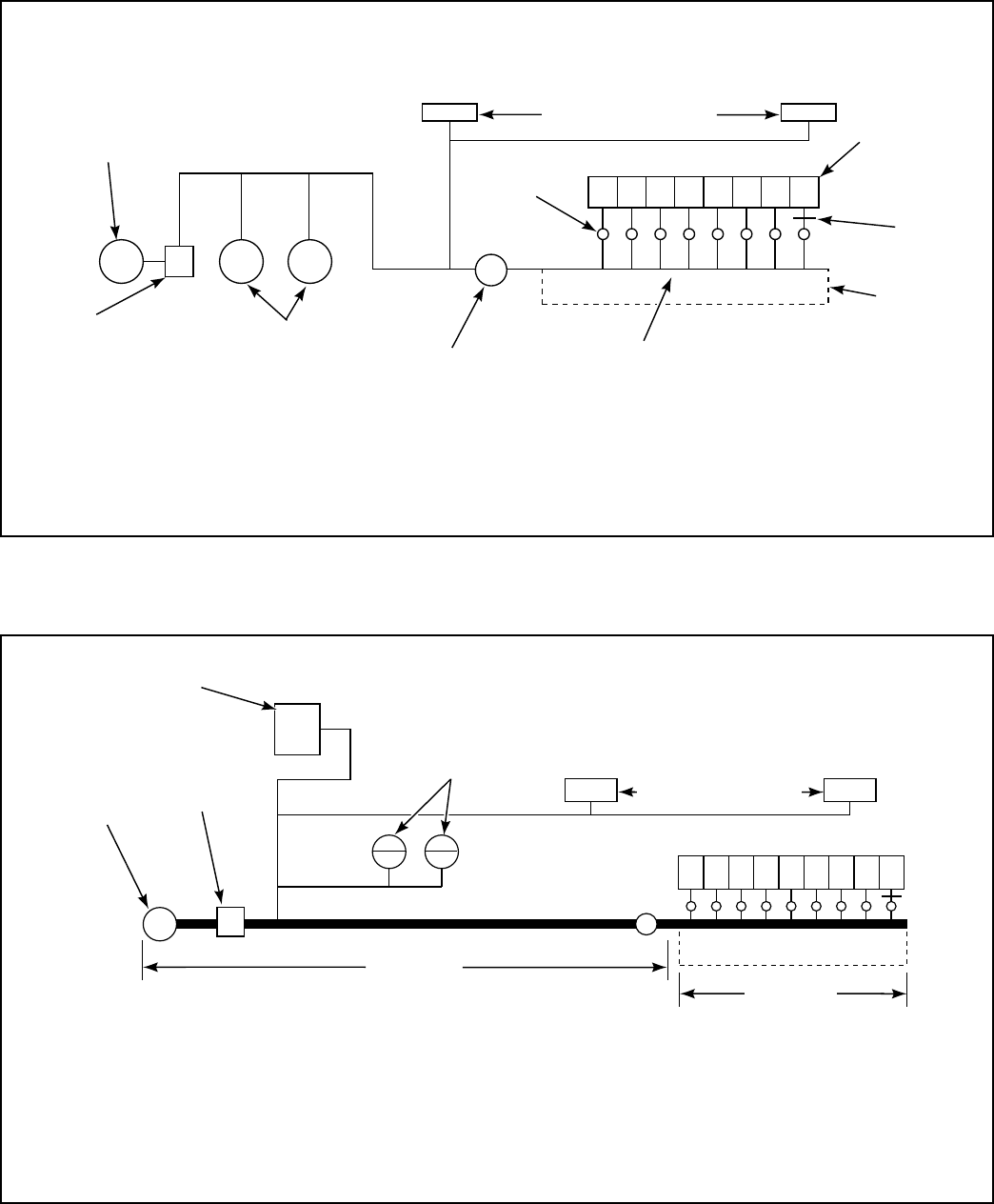

Example of Gas Supply Piping

Figure 8

GAS

METER

IMPORTANT: Gas loop piping must be installed

as illustrated to equalize gas pressure for all

tumblers connected to single gas service.

Other gas using appliances should be

connected upstream from loop.

IMPORTANT: Line pressure must be maintained at 6-1/2 ± 1-1/2 water column inches (1.62 ± .37 kPa) for Natural Gas

(11 ± .3 water column inches for L.P. Gas) (2.74 ± .07 kPa) with all gas appliances running (tumblers, water heaters, space heaters,

furnace, etc.).

An in-line pressure regulator may be required on Natural Gas models if the line pressure exceeds eight water column inches (2.00

kPa) pressure with all gas appliances firing.

GAS LINE

PRESSURE TAP

TUMBLERS

ONE INCH

(2.54 cm)

PIPE

GAS LOOP

NOTE: Minimum pipe size to

tumbler is 1/2" (12.7 mm)

GAS SPACE HEATER

GAS

SHUT-OFF

VALVES

PRESSURE

REGULATOR

(If required)

GAS WATER

HEATERS

MAIN

REGULATOR

T034IE3D

123456789

TMB1960N

SAMPLE CALCULATIONS:

Equivalent Length = Total length of main gas supply pipe from

the gas meter to the far end of the tumbler dryers.

= 25' + 19' (7.6 m + 5.8 m) gas supply pipe.

= 44' (13.4 m) Total Gas Liner

GAS

FURNACE

(120,000 BTU/HR.)

GAS WATER

HEATERS

(400,000 BTU/HR. each)

MAIN

REGULATOR

GAS TUMBLER DRYERS

(75,000 BTU/HR. each)

GAS

METER

NOTE: See BTU/HR. rating

on dryer nameplate.

19' (5.8 m)

25' (7.6 m)

PRESSURE

REGULATOR

Total BTU/HR = The sum of the BTU/HR. of all

tumblers being fed by the main

gas supply pipe.

= 9 x 75,000

= 675,000 BTU/HR.

19' (5.8 m)

GAS SPACE

HEATERS

(70,000 BTU/HR. each)

The main supply pipe diameter should be 2" (5.08 cm). Refer to Table 2.