28

3. Depress the tabs on the rotational sensor harness plug and pull apart.

4. Remove the retaining ring from the tumbler shaft.

5. Remove the four (4) bolts, lock washers and flat washers securing the flange bearing to the dryer cabinet.

6. Loosen the set screws from the flange bearing.

7. Remove the flange bearing from the tumbler shaft.

8. To replace new flange bearing reverse Step #2 through Step #8.

9. Reestablish electrical power to the dryer.

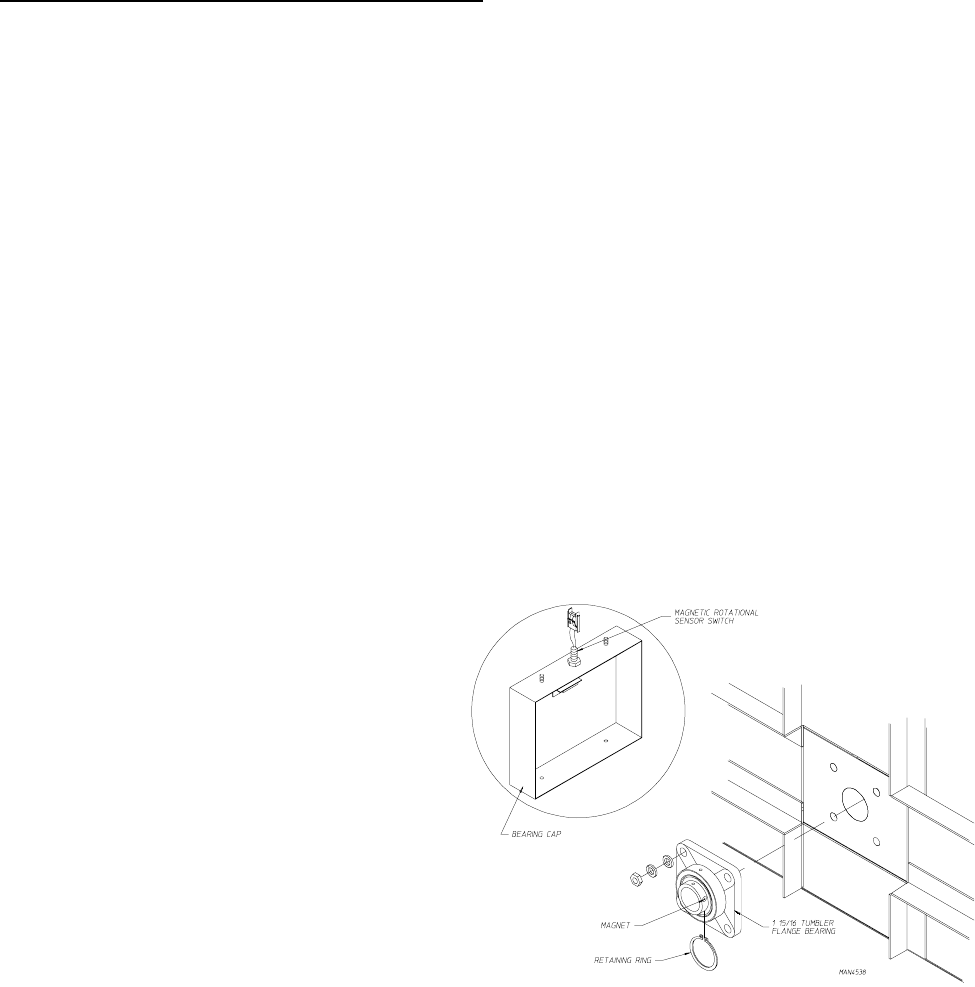

K. ROTATIONAL SENSOR ASSEMBLY

The Rotational Sensor Assembly is located in the rear of the dryer. It consists of a magnet which rotational

switch, mounted to the bearing cap is riveted to the 1-15/16 (5 cm) Flange Bearing.

The magnetic rotational sensor switch senses the rotation of the tumbler (basket). If the gap between the sensor

switch and the magnet is greater than a preset amount, then the dryer will shut down on SEFL (rotational

sensor failure).

1. To Replace Rotational Sensor Switch.

a. Discontinue electrical power to the dryer.

b. Remove the bearing cap from the dryer.

c. Remove the adjustment nut from the bearing cap.

d. Remove the magnetic rotational sensor switch from the bearing cap.

e. Depress the tabs on the rotational sensor harness plug and pull apart, then remove the sensor switch.

f. To install a new sensor switch, connect the plug of the new sensor switch to the sensor harness.

g. Place one (1) adjustment nut onto the sensor

switch and insert into the bearing cap.

h. Place the second adjustment nut on but DO

NOT TIGHTEN. The magnet on the

Flange Bearing and the sensor switch must

be in a horizontal line to one another.

i. The gap between the magnet and the sensor

switch must be 1/8-inch.

j. Tighten the adjustment nuts installed in Step

#6 and Step #7.

k. Reestablish electrical power to the dryer.