© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

Operation

11

AJ0976

10. Place level along inside carriage rail at C and

raise or lower either end of press as necessary.

Turn leveling bolts equal amounts to maintain

alignment at A and B.

11. Use a level to recheck A, B, and C.

12. Turn two center leveling bolts until they just

touch the floor.

13. Tighten leveling bolt jam nuts and bolt press to

floor.

14. Use a level to recheck A, B and C.

15. Install two 5/8" washers on each of the 5/8"-11

Grade 5 anchoring bolts.

16. Place anchoring bolts with washers into

expansion anchors.

17. Tighten all anchor bolts and torque to 80 ft./lbs.

18. Use grout if required.

Items Shipped in Box

A cardboard box is shipped inside press cabinet. It

includes:

● Hi-temp lubricant

● Installation and Operation Manuals

● Eccentric wrench

NOTE: Eccentric wrench will be used later for

adjusting buck carriage roller throughout life of

press. Keep hi-temp lubricant for maintenance.

Figure 4

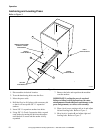

Connecting Steam Supply and

Returns

Refer to Figure 5.

NOTE: Clean out all pipe lines before connecting

them to the press.

IMPORTANT: Failure to properly install suitable

traps and check valves and supply correct steam

pressure will reduce operating efficiency.

Steam supply connected to press must have a constant

minimum pressure of 110 psi (7.58 bar).

The following steps outline the procedure for

connecting steam supply and return lines to press.

1. Run a 1-1/4 inch NPT steam line to the steam

supply connection with suitable black iron pipe,

elbows, strainer, ball valve and union.

IMPORTANT: A minimum 3 inch (7.62 cm) riser

should be installed off the supply header to

minimize water in the steam supply to the press.

NOTE: It is recommended that a steam strainer be

installed between the steam supply and press.

2. Install three suitable 1/2 inch NPT steam traps,

unions, check valves and ball valve between

steam return connections and steam return lines.

NOTE: Cast iron inverted bucket traps are

recommended. Size traps according to steam

pressure and consumption found in Utility

Specifications.

Figure 5

CAB412N

CAB412N

7.75 in.

(197 mm)

12.25 in.

(311 mm)

MOUNTING HOLES

(6 PLACES)

0.8125 in. (21 mm)

3 in.

(76 mm)

28 in.

(711 mm)

65.25 in.

(1657 mm)

17.75 in.

(451 mm)

BASE PADS

102 in.

(2591 mm)

5 in.

(127 mm)

MOUNTING HOLES

CAB413N

CAB413N

REQUIRED PIPING

HOOKUP BY CUSTOMER

AIR SUPPLY

(0.25 in. NPT)

STEAM

STRAINER

3 in. MIN.

HEADER

STEAM TRAP

BALL VALVE

UNION

RISER

CHECK VALVE

UNION

STEAM LINE

(1.25 in. NPT)