Installation

44

F232062

Water Connection

Connections should be supplied by a hot and

a cold water line of at least the sizes shown

in the Water Supply Line Sizing table.

Installation of additional machines will require

proportionately larger water lines. See table.

To connect water service to machine with

rubber hoses, use the following procedure:

1. Before installing hoses, flush the water

system for at least 2 minutes.

2. Check filters in the machine’s inlet hoses

for proper fit and cleanliness before

connecting.

3. Hang hoses in a large loop; do not allow

them to kink.

If additional hose lengths are needed, use

flexible hoses with screen filters. Each hose

should have a screen filter installed to keep

rust and other foreign particles out of the water

inlet valves.

Pressure of 30 – 85 psi (2 – 5.7 bar) provides

best performance. Although the machine will

function properly at lower pressure, increased

fill times will occur.

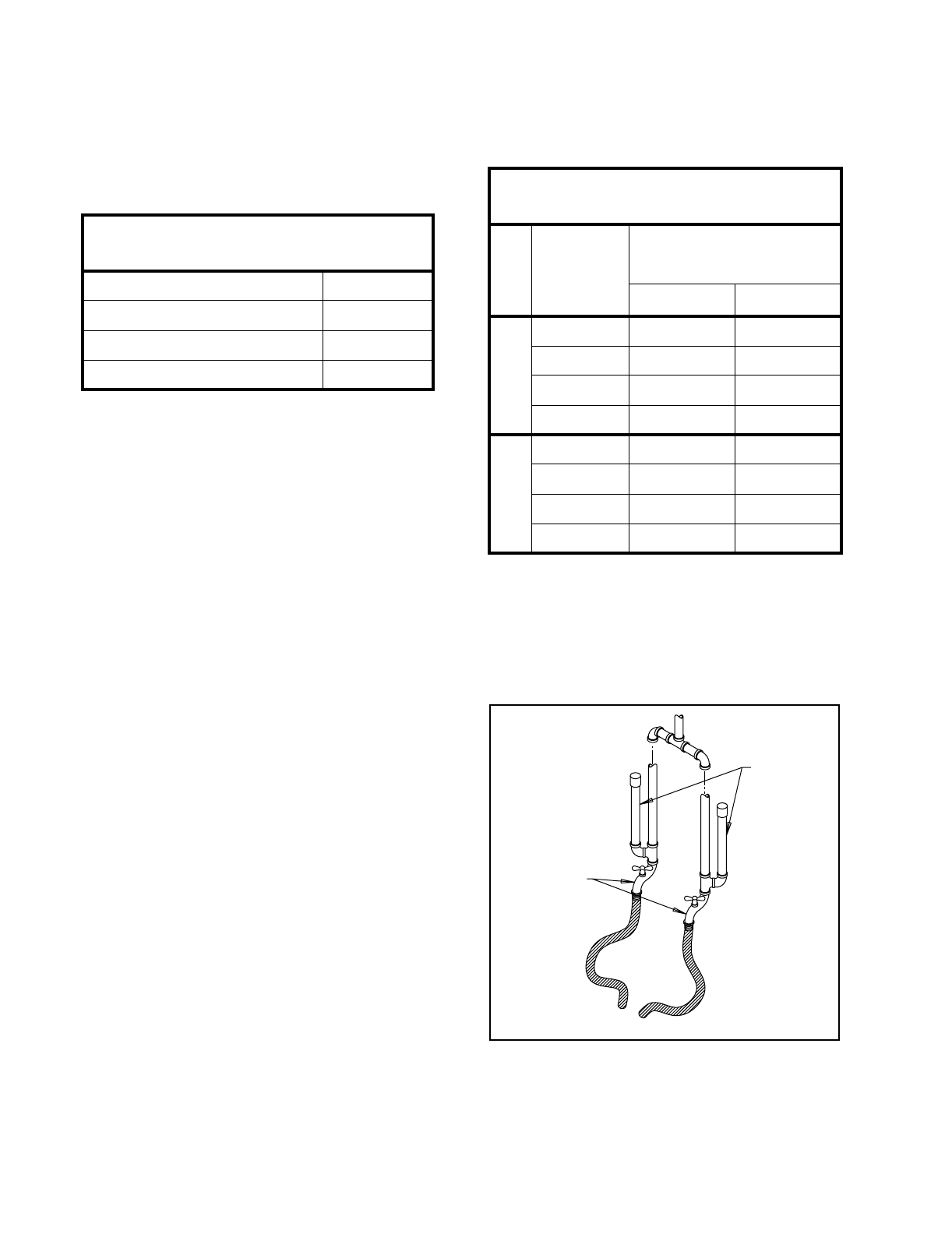

Suitable air cushions should be installed in

supply lines to prevent “hammering.” See

Figure 38. If the water pressure is above

60 psi, flexible copper tubing should be used in

place of rubber hoses.

Figure 38

Cabinet Hardmount

Water Supply Information

Water inlet connection size, in (mm) 3/4 (19)

Number of water inlets (standard) 2

Recommended pressure, psi (bar) 30 – 85 (2 – 5.7)

Inlet flow capacity, gal-min/l-min (80psi) 12 (45)

Cabinet Hardmount

Water Supply Line Sizing

Capacity

Number

Of

Machines

Supply Line Size

[in (mm)]

Main Hot/cold

18 – 50

1 3/4 (19) 3/4 (19)

2 1 (25) 3/4 (19)

3 1-1/4 (32) 1 (25)

4 1-1/2 (38) 1 (25)

80

1 1 (25) 3/4 (19)

2 1-1/2 (38) 1 (25)

3 2 (50) 1-1/4 (32)

4 2 (50) 1-1/2 (38)

MW008JE1A

Air Cushions

(Risers)

Water Supply

Faucets