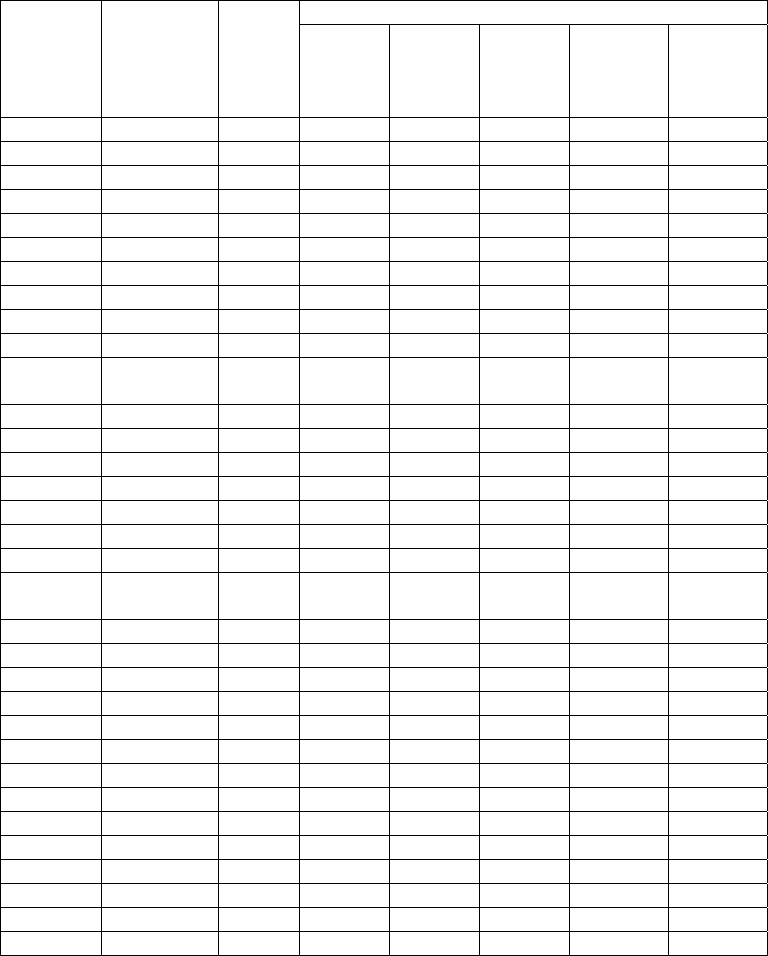

10 CFM Compressed Air Dryer Chapter 7: Appendix 28 of 30

Dryer Operating Parameters

Drying Hopper Capacity,* lbs./hr (kg/hr) Material Drying

Temp, ºF,

(ºC)

Drying

time in

hours

Initial

moisture

content.

H

2

0 in %

Final

moisture

content

H

2

0 in %

0.4 cu. ft.

(11 liter)

drying

hopper

0.8 cu. ft.

(22 liter)

drying

hopper

0.9 cu. ft.

(25 liter)

drying

hopper

ABS 176 (80) 2-3 0.45 0.15 5.6 (2.5) 11.2 (5.1) 12.6 (5.7)

ASA 212 (100) 3 4.6 (2.1) 9.2 (4.2) 10.4 (4.7)

CA 176 (80) 2-3 0.7 0.15 5.6 (2.5) 11.2 (5.1) 12.6 (5.7)

CP 167 (75) 2-3 1.0 0.15 5.6 (2.5) 11.2 (5.1) 12.6 (5.7)

EVA 176 (80) 2-3 5.6 (2.5) 11.2 (5.1) 9.0 (4.1)

Ionomere 194 (90) 3.5 4.0 (1.8) 8.0 (3.6) 5.2 (2.3)

PA11 167 (75) 4-6 0.7 0.07 2.8 (1.3) 5.6 (2.5) 6.3 (2.9)

PA12 167 (75) 4-6 0.7 0.07 2.8 (1.3) 5.6 (2.5) 6.3 (2.9)

PA6 176 (80) 4-6 0.5 0.05 2.8 (1.3) 5.6 (2.5) 6.3 (2.9)

PA6.6 176 (80) 4-6 0.5 0.05 2.8 (1.3) 5.6 (2.5) 6.3 (2.9)

PA6.6

GF35

176 (80) 4-6 0.5 0.04 2.8 (1.3) 5.6 (2.5) 6.3 (2.9)

PBT 266 (130) 3-4 0.25 0.02 4.0 (1.8) 8.0 (3.6) 9.0 (4.1)

PC 248 (120) 2-4 0.16 0.01 4.6 (2.1) 9.2 (4.2) 10.4 (4.7)

PE Filled 185 (85) 3-4 0.5 0.02 4.6 (2.1) 9.2 (4.2) 10.4 (4.7)

PE 194 (90) 1-2 0.05 0.01 7 (3.2) 14 (6.4) 15.8 (7.1)

PEEK 302 (150) 4 3.5 (1.6) 7 (3.2) 7.9 (3.6)

PEI 302 (150) 4 0.25 0.01 3.5 (1.6) 7 (3.2) 7.9 (3.6)

PES 302 (150) 4 0.43 0.02 3.5 (1.6) 7 (3.2) 7.9 (3.6)

PETP 300-392

(150-200)

4-6 0.25 0.002 2.3 (1.0) 4.6 (2.1) 5.2 (2.3)

PETG 149 (65) 4-5 0.1 0.04 3.5 (1.6) 7 (3.2) 7.9 (3.6)

PMMA 176 (80) 2-3 0.25 0.02 5.6 (2.5) 11.2 (5.1) 12.6 (5.7)

POM 212 (100) 3-4 0.2 0.05 4.6 (2.1) 9.2 (4.2) 10.4 (4.7)

PP 194 (90) 2 0.1 0.05 7 (3.2) 14 (6.4) 15.8 (7.1)

PPO 212 (100) 2-3 0.2 0.02 5.6 (2.5) 11.2 (5.1) 12.6 (5.7)

PPS 284 (140) 3-4 0.1 0.05 4.6 (2.1) 9.2 (4.2) 10.4 (4.7)

PS 176 (80) 1-2 0.05 0.02 7 (3.2) 14 (6.4) 15.8 (7.1)

PSU 302 (150) 3-4 0.3 0.05 4.6 (2.1) 9.2 (4.2) 16.4 (7.4)

PUR 176 (80) 3-4 0.4 0.01 4.6 (2.1) 9.2 (4.2) 16.4 (7.4)

PVC 158 (70) 1-2 0.3 0.10 9.3 (4.2) 18.6 (8.4) 41.9 (19)

SAN 176 (80) 2-3 0.3 0.03 5.6 (2.5) 11.2 (5.1) 25.2 (11.4)

SB 176 (80) 2 0.3 0.03 7 (3.2) 14 (6.4) 31.5 (14.3)

TPE 230 (110) 3-4 4.6 (2.1) 9.2 (4.2) 16.4 (7.4)

TPU 194 (90) 2-3 0.4 0.02 5.6 (2.5) 11.2 (5.1) 12.6 (5.7)

* Performance may vary based on initial quality of the compressed air supply to the dryer.