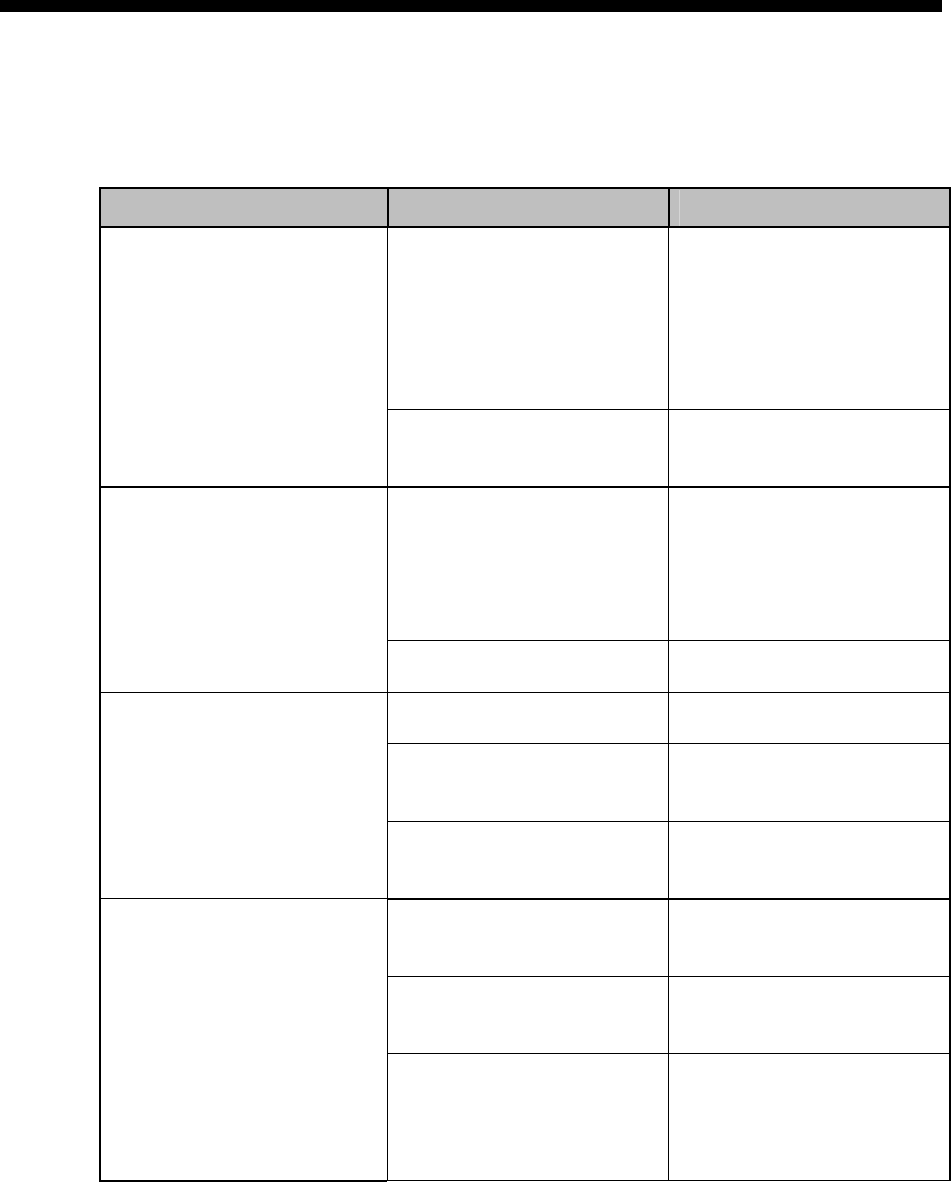

10 CFM Compressed Air Dryer Chapter 6: Troubleshooting 23 of 30

Chapter 6: Troubleshooting

The utmost in safety precautions should be observed at all times when working on or around

the machine and the electrical components. All normal trouble-shooting must be

accomplished with the unit turned off, power disconnected, and with the machine tagged as

out of service.

Problem Possible Cause Possible Remedy

Material being dried differs

from material specified at the

time of purchase.

Drying systems are designed

for the material that was

originally specified.

Different materials may need

a longer residence time or a

different drying temperature.

Loss or reduction in drying

capacity.

Break in flex hose to drying

hopper.

Inspect for air leaks; replace

as needed.

Process temperature set too

high due to operator error.

Check resin manufacturer’s

data sheet for proper drying

temperature. Make sure plant

personnel are aware of the

correct process temperature

set point.

Material in drying hopper

cakes, or meltdown occurs.

High temperature alarm not

set properly.

Reset high temperature

alarm.

Process set point is out of

acceptable range.

Restore temperature

controller to factory pre-sets.

Function set for degrees

Celsius (ºC), set point at

degrees Fahrenheit (ºF).

Verify correct Celsius or

Fahrenheit settings.

Nothing displays when the

controller is turned on.

Process thermocouple not in

airflow.

Verify that the thermocouple

is properly installed in the

inlet tube.

The internal mechanism is

not inserted properly into the

housing.

Properly insert the internal

mechanism into the housing.

The power supply is not

connected to its terminals

properly.

Properly connect the power

supply to the power supply

terminals.

No setting change possible on

temperature controller.

No power is supplied, or the

supplied power is not within

the specified range.

Supply a voltage of 85 to

125 VAC to the power

supply terminals of the

controller or 220-240 V for

higher voltage units.