10 CFM Compressed Air Dryer Chapter 5: Maintenance 21 of 30

Chapter 5: Maintenance

This dryer is designed to be virtually maintenance-free. This unit is factory-sealed. Any

service required on this unit must be performed by factory personnel at the manufacturer’s

facility.

WARNING!

The 10 cfm compressed air dryer is sealed at the factory. Removing

this seal and opening the box that houses the dryer will void your

warranty. Please contact the manufacturer for assistance.

5-1 Preventative Maintenance Schedule

Inspect all filters for wear, and replace/clean if dirty or worn

Weekly

Check to make sure that all hose connections are air tight

Monthly Lock out electrical power and inspect the main power supply for integrity.

5-2 Cleaning and Replacing the Filters

The 10 cfm compressed air dryer uses a large particle air filter in the process air system to

clean the compressed air before it enters the drying cabinet. The optional remote-mount

membrane dryer assembly features a coalescing filter in addition to the large particle air filter.

Regular filter cleaning is essential to keep the dryer operating at peak efficiency.

Use the following procedure to clean or replace the process air filter or the membrane dryer

coalescing filter:

1. Turn off and lock out electrical power to the dryer.

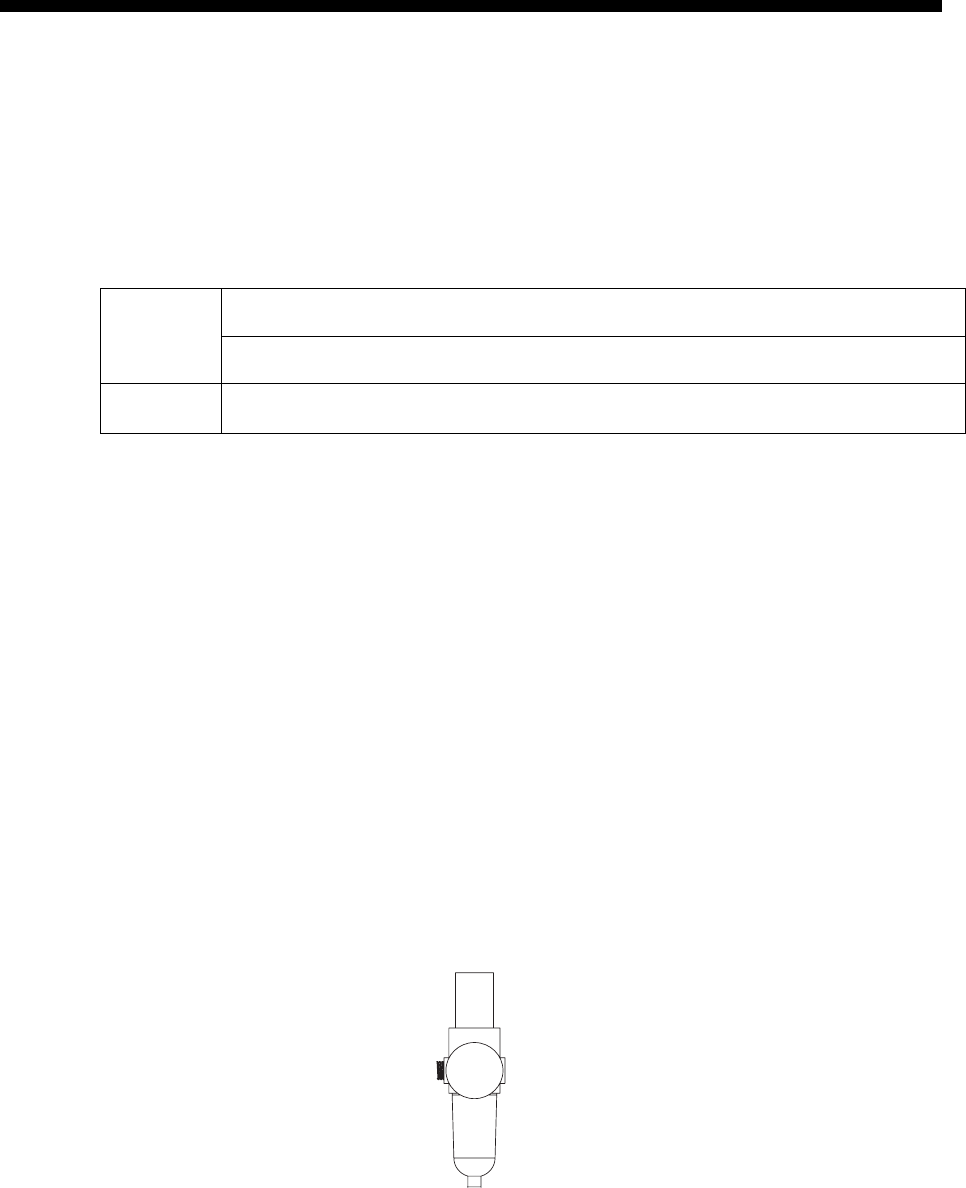

2. Remove the clear bowl at the bottom of the filter. (See Figure 6).

3. Discard the contents of the clear filter bowl.

4. Visually inspect the filter element.

5. If needed, clean the filter element with compressed air or replace it.

Caution! Do not clean or wash the filter with water.

6. Replace the clear bowl.

Figure 6: Large Particle Filter