Procedures

1. Sketch the heater wiring configuration so you can properly re-wire the heater.

2. Remove the ceramic nuts and wires to the heater plate assembly being removed or

replaced.

3. Remove the six (6) 10-32 button head screws securing the process heater plate using

a 1/8” Allen wrench and slide out the assembly.

4. Remove the heater(s) from the mounting plate by removing the large brass nuts and

washers.

5. Re-install the heater(s) and heater plate assemblies in reverse order. Install new

heater gaskets and securely tighten all fasteners.

Caution! Heater loops should not touch each other.

“Hot spots” lead to premature heater failure!

6. Reinstall the wires based on the sketch you made earlier.

7. Reinstall the ceramic nuts to each heater terminal.

Replacing/Cleaning the Cooling Coils

WARNING! Hazardous electrical current present.

Disconnect and lock out power before you replace heater elements!

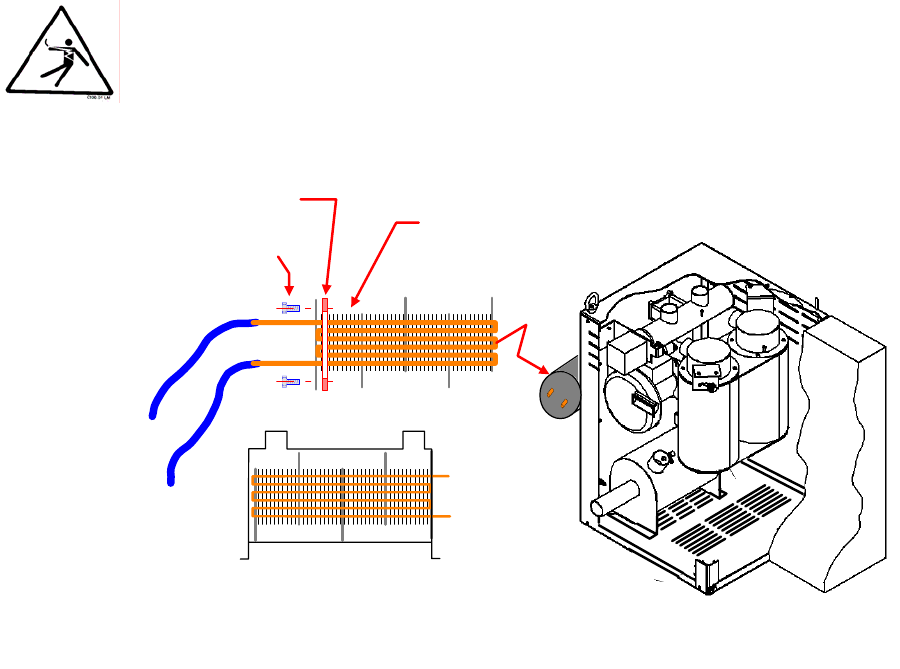

Figure 11: Cooling Coil Location and Disassembly

Note: To clean the cooling coil, use compressed air or a steam

cleaner to blow the dust off or clean any oily residue on the

coil.

Undo (4) 10-32 Button

Head Screws using 1/8

Allen Wrench

Use compressed air or a steam

cleaner to blow the dust off or clean

any oily residue on the coil.

1" Wide x 1/8" Thick High

Temperature Gasket

Water flow requirement:

If used as an After-Cooler: 3 to 4 GPM @80F.

If used as a Plasticizer Trap: 3 to 4 GPM @ 40F to 45F.

Portable Drying/Conveying Systems Chapter 5: Maintenance 46 of 63