Figure 9: Required Desiccant Amounts

Dryer 8 x 12 bead Total

model Part no. lbs. Kg

15 cfm 7.0 3.25

30 cfm 15.75 7.25

60 cfm

W00018051

37.5 17.0

Replacing the regeneration heaters

Procedures (see figure 8).

1. Sketch the heater wiring configuration so you can properly re-wire the heater.

5 Remove the ceramic nuts and wires to the heater plate assembly being removed or replaced.

6 Remove the six (6) 10-32 button head screws securing the process heater plate using a 1/8” Allen

wrench and slide out the assembly.

7 Remove the heater(s) from the mounting plate by removing the large brass nuts and washers.

8 Re-install the heater(s) and heater plate assemblies in reverse order. Install new heater gaskets and

securely tighten all fasteners.

Caution! Heater loops should not touch each other.

“Hot spots” lead to premature heater failure!

2. Reinstall the wires based on the sketch you made earlier.

Reinstall the ceramic nuts to each heater terminal.

Replacing the Process Heater

The dehumidifying dryers utilize a single-phase Calrod-type heater element. This heater

element is mounted in the center compartment below the desiccant beds. Although the

replacement procedure is the same for each heater, the wattage varies by model, voltage,

temperature range, etc.

WARNING! Hazardous electrical current present.

Disconnect and lock out power before you replace heater elements!

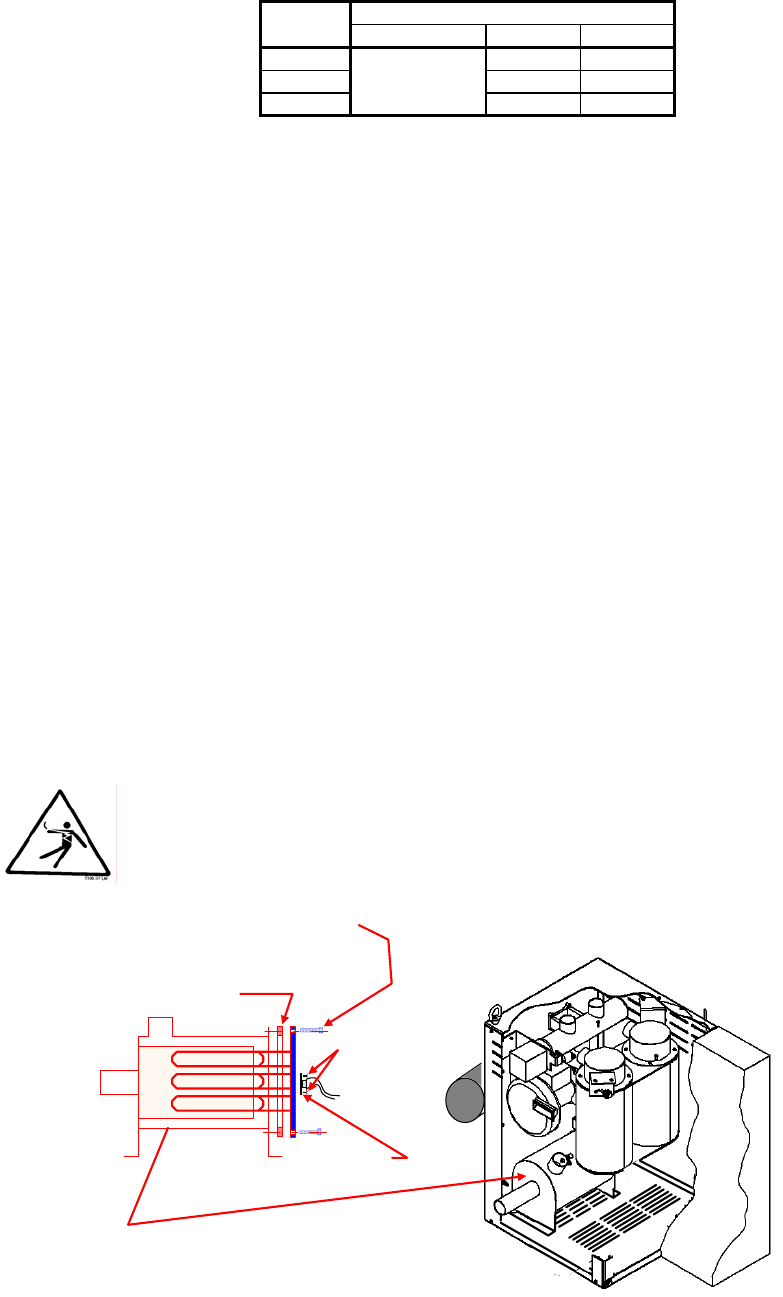

Figure 10: Process Heater Location and Disassembly

Undo (6) 10-32 Button

Head Screws using 1/8

Allen Wrench

1" Wide x 1/8" Thick High

Temperature Gasket

(2) 4-40 screws

Hi Temperature

Snap Switch

Portable Drying/Conveying Systems Chapter 5: Maintenance 45 of 63