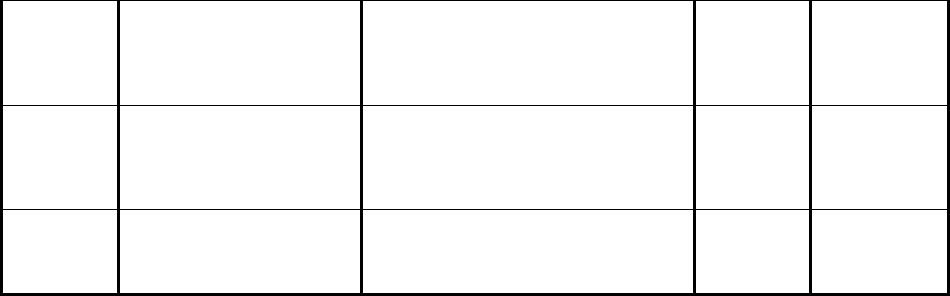

UdSP Upper Display Look

None, Process Value, Limit 1 Low Set,

Limit 1 High Set, Limit 2 Low Set, Limit

2 High Set, Alarm 2 Low Set, Alarm 2

High Set, Limit 3 Low Set, Limit 3 High

Set, Alarm 3 Low Set, Alarm 3 High Set

Process -

LdSP Lower Display Look

None, Process Value, Limit 1 Low Set,

Limit 1 High Set, Limit 2 Low Set, Limit

2 High Set, Alarm 2 Low Set, Alarm 2

High Set, Limit 3 Low Set, Limit 3 High

Set, Alarm 3 Low Set, Alarm 3 High Set

Limit 1

High Set

-

LOC Lockout

(0) no lockout, (1) Programming and

Setup Page Locked, (2) Limit Set

Points are the only Operation Page

parameters accesible, (3) Full Lockout.

0 2

4-2 System Operation Procedures

1. Turn the disconnect switch on the control panel to the ON position. Power is applied to the voltage

line fuses and line side of the control power switch.

2. Turn the control power switch to the

ON position. Power is applied to the PLC and touch screen.

Push the start button on the PLC and the valve will move to the start position as follows:

a. The valve motor rotates until the cam switch makes 2 transitions.

b. If the cam switch does not make a transition within 10 seconds, a valve

motor fault alarm is generated. The alarm horn and light are activated. The

valve motor, heaters, and blower shut off. Pressing the

ALARM SILENCE

pushbutton will deactivate the alarm horn and light.

Note: Cycle control power to restart the dryer.

c. The valve will normally complete one full cycle (revolution). If sequence

shutdown is not initiated (in 10 Seconds) and control power switch or

disconnect are turned off:

1. The bed in process at power-down will remain in

process.

2. The bed in regeneration at power-down will remain in

regeneration.

3. The regeneration timing cycle will restart from the

beginning.

3. Once the control power is on and no fault conditions exist, turning the Off-On switch to the ON

position and pressing the

START button on the touch screen will start the dryer as follows:

a. The process heater is turned on and controlled by the PLC.

b. The process/regen blower is started.

c. The regen heater is turned on and the regeneration timing sequence is

initiated. The regen heater is controlled by the PLC.

Portable Drying/Conveying Systems Chapter 4: Operation 38 of 63