—

10

—

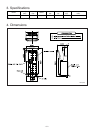

• Measure the winding resistance. (Measure the

resistance values between "black and white," "red and

black," and "white and red" wires of the 1-pin

connector coming from the motor.)

* Replace the motor if the measured values are other

than the normal value shown in

the table at right.

• Replace the control circuit if other than above.

• Is a rated power supply voltage of 220 to 240 V being

applied?

• Is a rated power supply voltage of 220 to 240 V being

applied?

• Is a power supply frequency 50 or 60 Hz?

• Replace the control circuit if other than the above.

Error mode display Cause Check procedure and action to take

1.Motor

2.Control circuit

1.Excess voltage applied

2.Low voltage

3.No power supply

frequency

4.Control circuit

• Replace the control circuit.

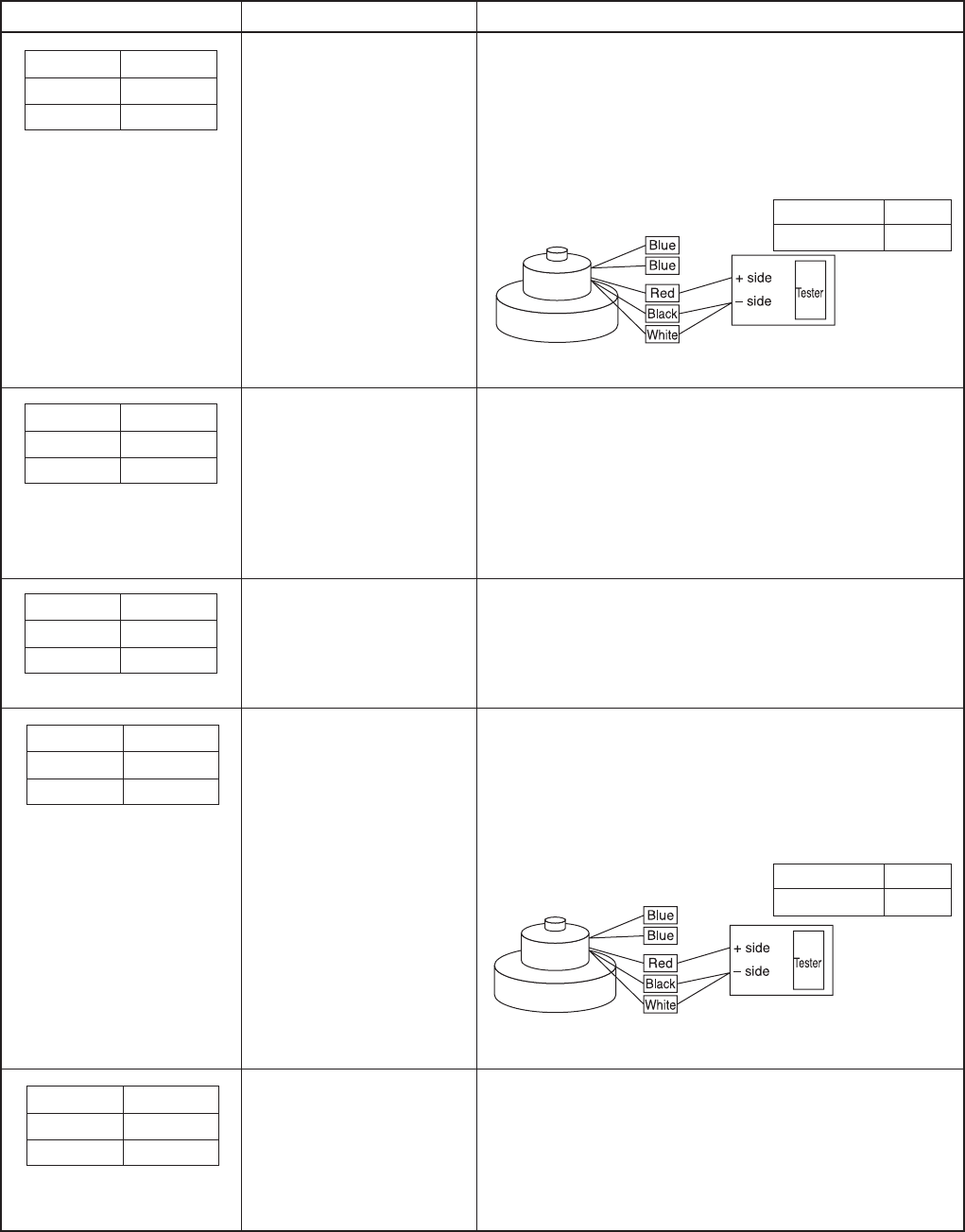

• Measure the winding resistance. (Measure the

resistance values between "black and white," "red and

black," and "white and red" wires of the 1-pin

connector coming from the motor.)

* Replace the motor if the measured values are other

than the normal value shown

in the table at right.

• Replace the control circuit if other than above.

• Replace the control circuit.

LED1 LED2

Power Inspection

●

✩

1.Control circuit

1.Motor

2.Control circuit

1.Control circuit

(Current detection circuit

abnormality)

LED1 LED2

Power Inspection

✩

●

(Motor lock)

LED1 LED2

Power Inspection

●

✩

(Overvoltage, low voltage,

power supply frequency

detection)

Measured value Decision

Approx. 3.4 to 3.7Ω Normal

LED1 LED2

Power Inspection

● ●

(Overcurrent detection)

Measured value Decision

Approx. 3.4 to 3.7Ω Normal

LED1 LED2

Power Inspection

●✻

(Microcomputer RAM abnormality)