9 GE Energy

Gas Turbines

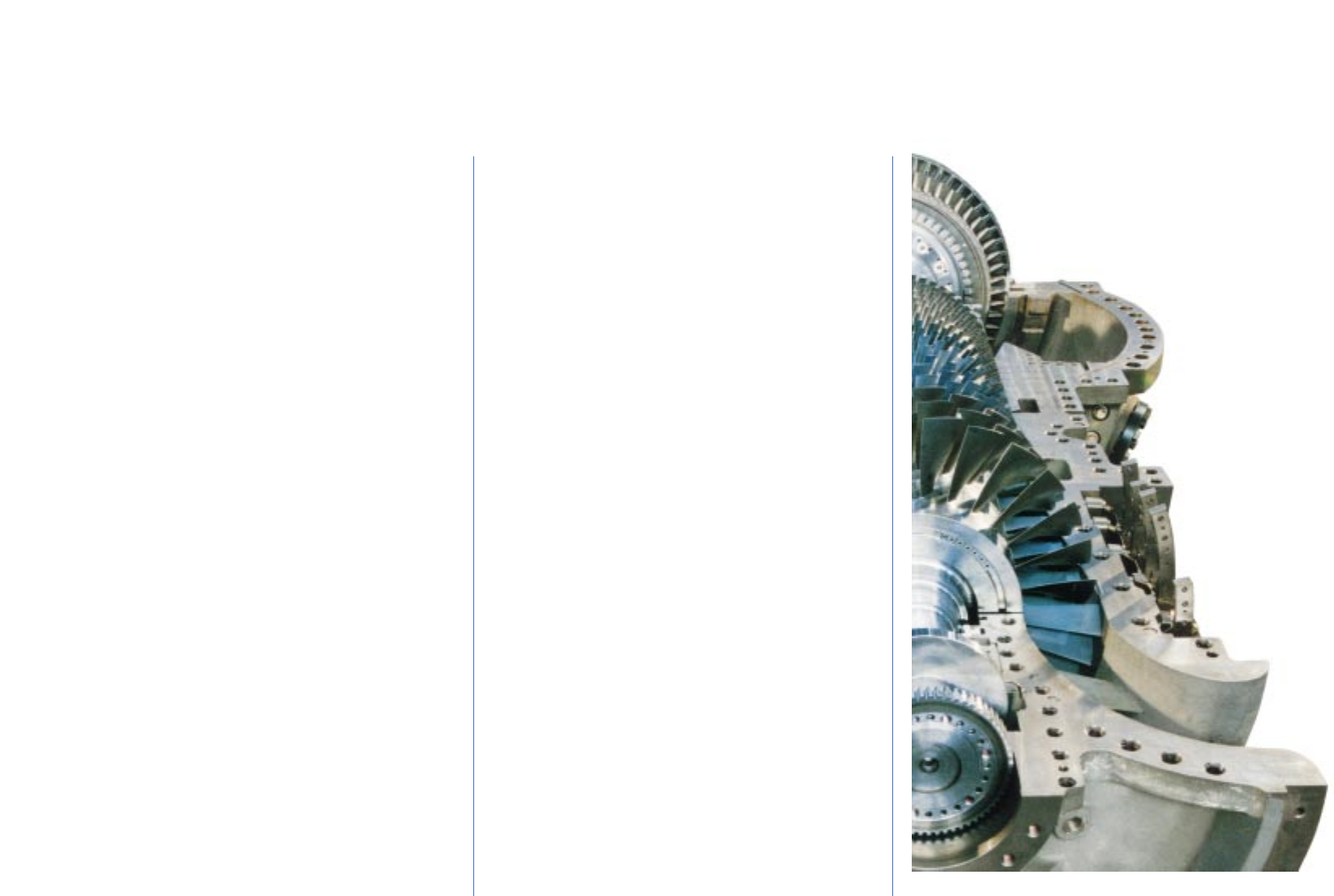

Mechanical Drive — Two Shaft Version.

The GE10-2 is the two shaft version of the GE10

intended for mechanical drive applications. The turbine

consists of four reaction stages. The first two stages or

High Pressure Turbine which are used to drive the axial

compressor are common with the GE10-1 model. The low

pressure shaft is a double stage, high-energy turbine with

variable first stage nozzles which provide maximum

flexibility for mechanical drive applications. These third and

forth stages which make up the Low Pressure Turbine are

coupled to the power shaft driving the load. They are

cooled by air bled from the axial compressor.

COMBUSTOR

The combustion system consists of a single, slot-cooled

combustion chamber assembly that permits quick and

easy maintenance of the hot gas path. This combustion

chamber is able to burn a wide range of fuels including

liquid distillates, residuals and all gaseous fuels including

low BTU gas with system modifications.

The GE10 combustion system is available in both

conventional and DLE configurations. The DLE (dry low

emissions) system is a simple, field-proven design that

guarantees operation at 25 ppmv NOx (burning Natural

Gas). The GE10 can also utilize steam and water

injection for NOx reduction and power augmentation.

Further reduction of emission levels is a constant

objective of our continuing combustion development

and test programs.

AUXILIARIES

The integrated lubrication system (including oil tank)

that feeds the gas turbine, the speed reduction gear and

the electric generator is located on the turbine base

plate. The main lube oil pump is mechanically driven by

the gearbox. An AC electric motor-driven pump

guarantees lubrication during normal operation while a

DC electric motor-driven pump is provided for

emergency backup. In the standardized package

configuration the oil is cooled by an air cooler. A water

cooler can be provided upon customer request.

The thrust and journal bearings are of the tilting pad type.

The starting system consists of a V.F.D. motor drive for the

single shaft version.

The twin shaft can be equipped with a torque converter

plus electric motor or starting expansion turbine.

The GE10 control system has been implemented to

assure a high degree of integration and standardization

between the engine and the turbine generator package.

Programmable modules guarantee easy

implementation of any control and protection scheme

to tailor the control system to the application and

customer needs.

PACKAGE

The package designed for power generation

applications is optimized to minimize plant dimensions

and to reduce maintenance cost and time. In the

standard configuration, the speed reduction gear is

mounted on the gas turbine base plate. The auxiliaries

are installed on a separate base plate permanently

joined to that of the gas turbine base plate to form a

single lift on which the sound-insulated enclosure is

mounted.

The electric generator is installed on a concrete

foundation to limit the shipping dimensions. The overall

length of the genset is about 13 m.

The other modules completing the system are the

oil/air exchangers, the air intake filter chamber, the

suction duct (vertical suction) and the exhaust system

(axial exhaust).

The enclosure has a sound pressure level lower than 85

dBA at 1 m. This acoustic design meets ISO NR 50 limits

at 100 m.