The PGT25 gas turbine consists of an LM2500 GE aeroderivative gas generator coupled with a

rugged, industrial power turbine designed by GE Energy.

GAS GENERATOR

The LM2500 GG has already accumulated several million fired hours not only as an aircraft

engine (TF39 and CF6-6 engines), but also in the industrial field in many mechanical drive

applications (marine, onshore and offshore gas transmission) and for generator drive service.

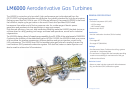

The LM2500 gas generator incorporates a 16-stage axial-flow compressor capable of reaching

an 18:1 pressure ratio. Inlet guide vanes and adjustable stator vanes on the first six compressor

stages provide for efficient operation over the entire operating range.

POWER TURBINE

The PGT25 power turbine components were designed by GE Energy taking into account many

years of experience gained in the field of heavy duty gas turbines and axial/centrifugal

compressors. The aerodynamic blading was designed with the main objective of obtaining very

high efficiency at both design and reduced speeds.

The 6500 RPM design speed means the turbine can have two stages with a moderate

aerodynamic load and a high expansion efficiency. The two expansion stages are of the high

energy, three-dimensional design type.

The investment casting superalloy selected for the blading assembly has a cobalt base for the

nozzles and a nickel base for the rotor blading (i.e. the same materials used on heavy-duty gas

turbines). A large creep and fatigue (LCF-HCF) safety margin on blade life is ensured by a

moderate gas temperature at the power turbine inlet. The two-stage rotor is overhung and the

shaft is supported by two tilting pad bearings contained in a cylindrical cartridge. The system

can be easily dismantled with a simple translation of the gas generator within the package

space thus reducing the time required for a major overhaul of the power turbine to a few days.

Engineering simplicity and advanced materials yield long time between overhauls and reduced

maintenance costs.

The turbine is assembled on a light but rigid base plate with extensive use of prefabricated

standard components preassembled and tested in the shop to minimize on-site assembly time.

GENERAL SPECIFICATIONS

Compressor

- Sixteen stage axial compressor

- Pressure ratio 17.7:1

Combustion

- Annular combustion chamber (30 fuel nozzles)

Turbine

- Two stage Gas Generator turbine

- Two stage Power turbine (6500 RPM).

Package

- Completely mounted on a single base plate

- The enclosure is integral with the base plate

providing maximum accessibility for maintenance

of the gas turbine and auxiliaries

Emission Control

- Steam or water injection systems for NOx abatement

- Dry Low Emission (DLE) combustion system

15 GE Energy

Gas Turbines

PGT25 Aeroderivative Gas Turbines

PGT25 Gas Turbine