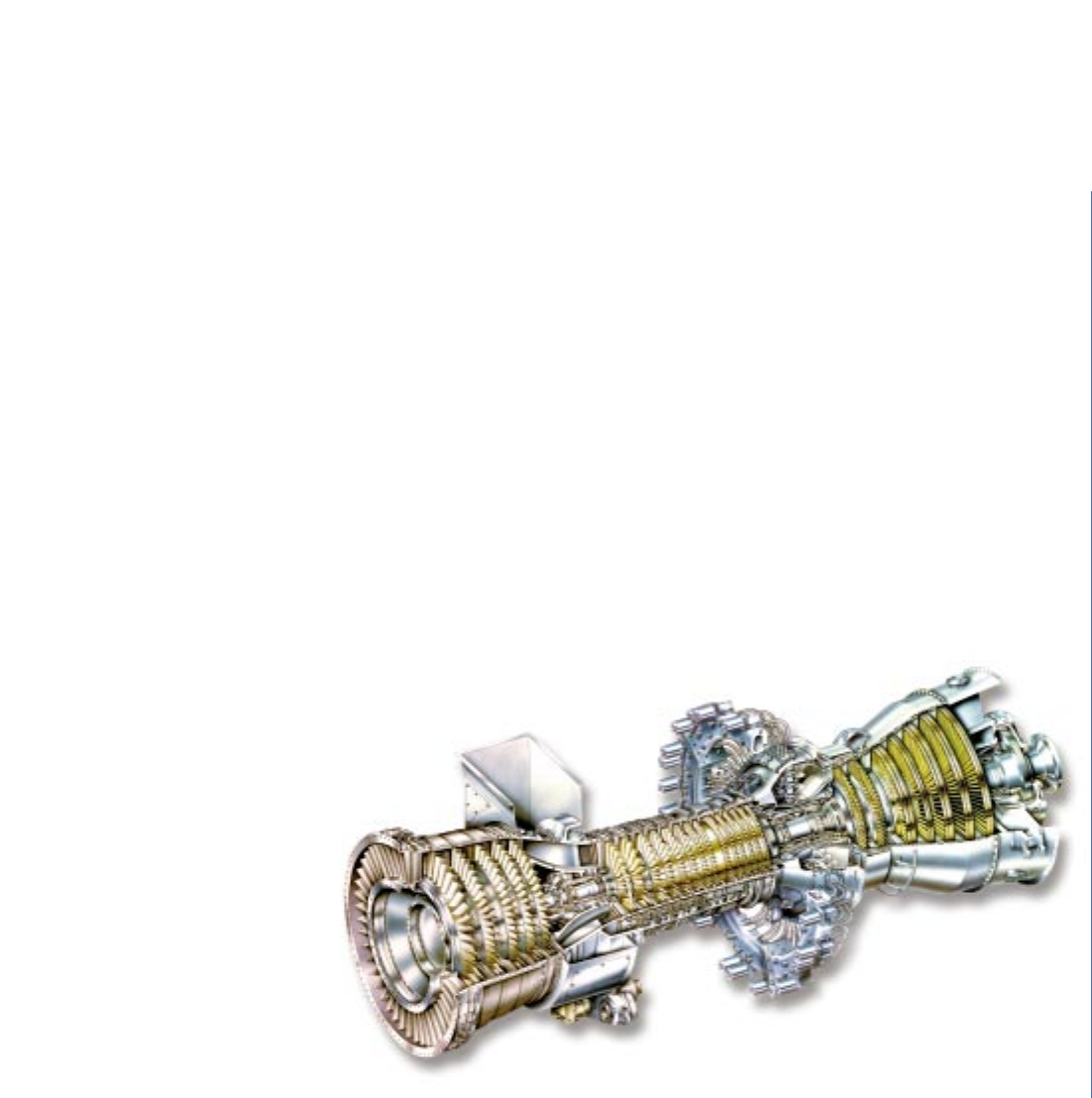

The LM6000 is a simple-cycle, two-shaft, high performance gas turbine derived from the

GE CF6-80C2 high bypass turbofan aircraft engine, the industry standard for high-thrust engines.

Delivering more than 44.8 MW at over 42.7% thermal efficiency, the powerful LM6000 is the most

fuel-efficient, simple-cycle gas turbine in the world. Direct drive provides 60,000 shaft

horsepower from either end of the low pressure rotor for a wide range of electric power

generation and mechanical drive applications in any environment.

High thermal efficiency, low cost, and installation flexibility make the LM6000 the ideal choice as

a prime driver for utility peaking, mid-range, and base load operations, as well as for industrial

cogeneration.

The LM6000’s design allows full speed range capability from 50-105% of the rated speed of 3600 RPM.

Continuing the tradition of the established record of GE’s LM2500, the LM6000 is ideal as a source

of drive-power for pipeline compression, offshore platform and gas re-injection, as well as for

LNG compressors. The LM6000 was GE’s first aeroderivative gas turbine to employ the new Dry

Low Emissions (DLE) premixed combustion system. DLE dual fuel, water or steam injection can

also be used to achieve low NOx emissions.

17 GE Energy

Gas Turbines

LM6000 Aeroderivative Gas Turbines

GENERAL SPECIFICATIONS

Compressor

- Two axial compressor (LPC, HPC)

- LPC five stage

- HPC fourteen stage

- Pressure ratio 28,5:1

Combustion

- Annular combustion chamber (30 fuel nozzles)

Turbine

- Two stage HPT

- Six stage LPT (3600 RPM)

Package

- Gas Generator, Power Turbine and auxiliary systems

mounted on a single base plate

- The enclosure is integral with the base plate providing

maximum accessibility for maintenance of the gas

turbine and auxiliaries

Emission Control

- Steam or water injection systems for NOx abatement

- Dry Low Emission (DLE) combustion system

LM6000 Gas Turbine