The MS5002 is a gas turbine specifically designed for mechanical drive applications such as gas

boosting, gas injection/re-injection, oil & gas pipelines, LNG plants and gas storage. It has a broad

operating speed range to meet the operating requirements of the most common driven equipment

(centrifugal compressors and pumps) as well as the ability to burn a large variety of gaseous and

liquid fuels. The MS5002 gas turbine was introduced in the market in the 1970s and has been

updated and up-rated over the years to meet the industry demand for increased output. Presently

two versions are available:

- MS5002C

- MS5002D

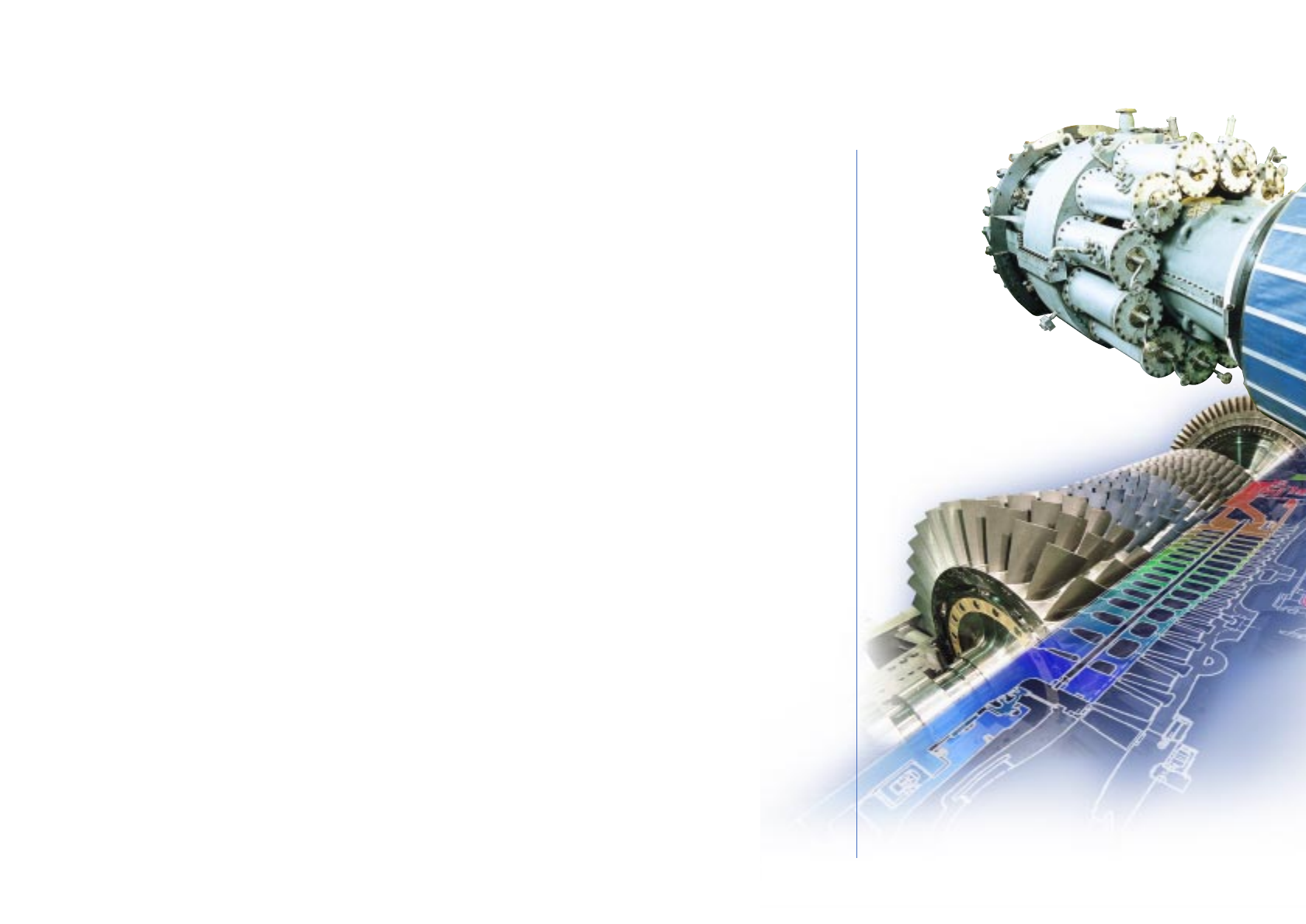

The MS5002 two-shaft, heavy-duty gas turbine is designed for high operating efficiency over a wide

range of speed and load. The simple design and extreme robustness of the MS5002 allow complete

maintenance to be performed on site without the need for specialized tooling or service shop

assistance. The main features of its design are:

- High pressure shaft consisting of a 16-stage (17 for MS5002D), axial-flow compressor and a

single-stage, high energy turbine. The first stage nozzles are air cooled and the second stage

nozzles are of the variable angle type.

- Low pressure shaft is a single stage, high energy turbine.

- Twelve combustion chambers are contained within a single wrapper. A wide range of gaseous

and liquid fuels can be burned. A DLN Combustion System is also available.

- A centralized lube oil system supplies clean, cooled, pressurized oil to lubricate the gas turbine

and the driven equipment including the oil required for any compressor seals.

As a consequence of the extremely favorable operating, maintenance and economic characteristics

of the MS5002 nearly 500 units (more than 300 manufactured by GE Energy) have been installed

world-wide in all types of environments (arctic, desert, off-shore etc.) always demonstrating ease of

operation and very high reliability and availability.

11 GE Energy

Gas Turbines

MS5002C-D Gas Turbines

MS5002 Gas Turbine