18 GE Energy

Gas Turbines

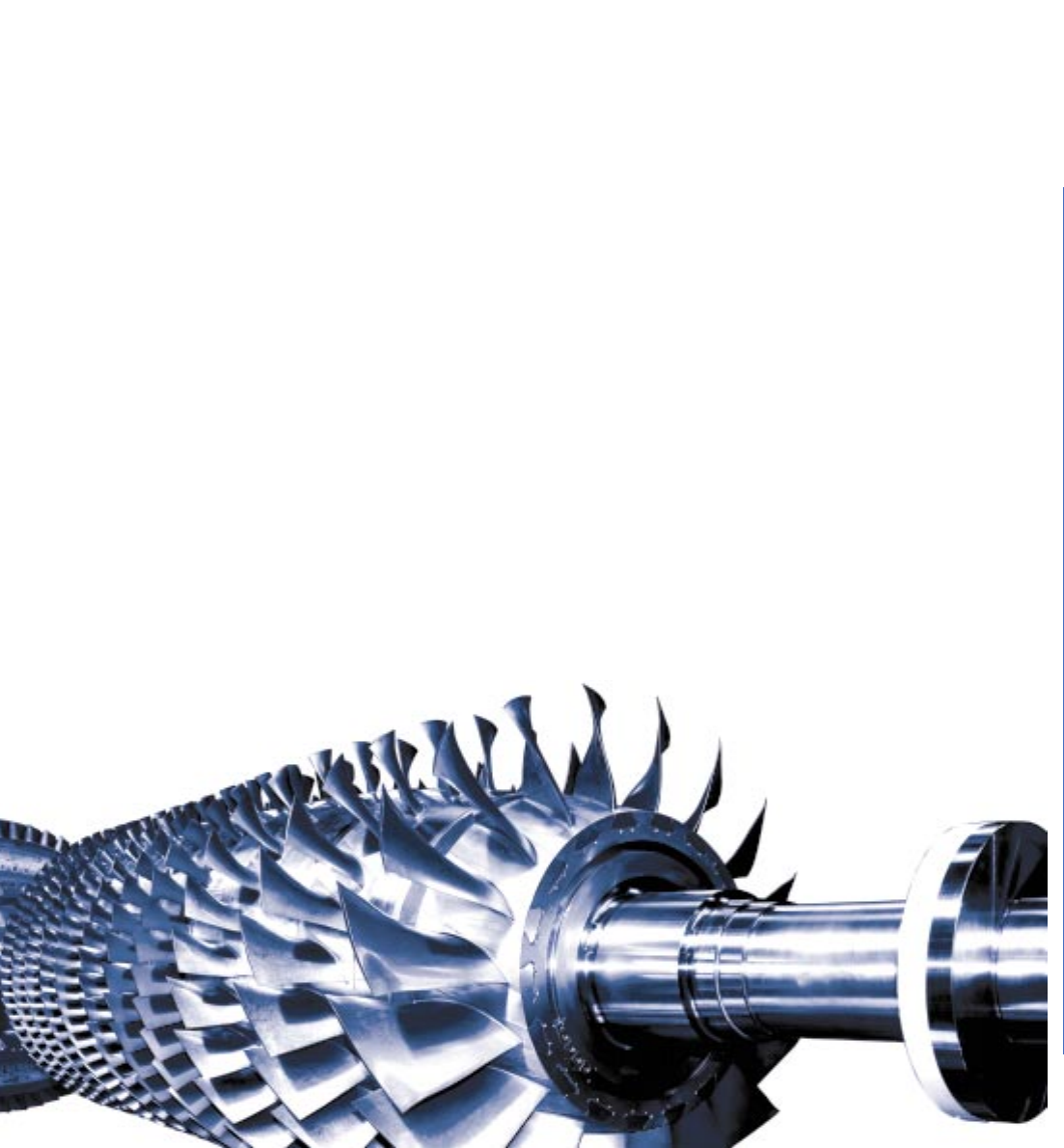

Axial Compressor

The compressor rotor is made of separately forged wheels (all models except the GE5 and part of

the GE10 which have a solid forged rotor). Each individual wheel undergoes inspection and is X-

rayed for material flaws. In addition, each wheel is balanced individually and the rotor is

balanced on three planes. Rabbet fits are used to ensure concentricity and multiple through-bolts

secure the wheels to form a correctly pre-stressed assembly. The blades are held in the

compressor rotor and stator rings by dovetail platforms. The stainless steel blades provide

excellent corrosion resistance and good internal damping characteristics. The large chord, broad-

blade compressor blades have low stresses and the unique ability to withstand damage by small

foreign objects as well as to maintain high performance in spite of normal wear and

contamination. The stator casing is horizontally split for ease of assembly, maintenance and

inspection. Iron castings give dimensional and thermal stability to maintain good radial tip

clearances for maximum power and efficiency. Several compressor designs are available

covering pressure ratios in the 8-17 range and air flows from 20 to 400 Kg/sec with 11-17 stage

configurations. The GE5, GE10 and MS5002E compressors have variable geometry, implemented

by means of adjustable vanes (inlet guide vanes and first stages stator vanes), in order to

provide flow control within the operating range.

Main Components