16

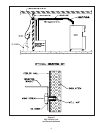

Figure 13. Auger with Rubber Rear Seal

Figure 14. Auger Disassembly

4. Keep the rear of the auger tipped up once it is

clear of the freezer barrel. This prevents the

auger seal from falling off.

5. Wipe spline lubricant off hex end rear of auger

with a paper towel.

3.16 DISASSEMBLY AND ASSEMBLY OF

AUGER

To aid in the disassembly and assembly of the auger,

refer to Figure 13 in the following steps:

CAUTION

TURN FREEZER OFF AT MAIN DRIVE SWITCH

BEFORE DISASSEMBLING FOR CLEANING AND

SERVICING.

A. Diassembly of auger

1. Remove the front auger support by pulling it

straight out of the freezer barrel.

2. Remove the plastic bearing from the front auger

support.

3. Remove the auger by pulling slowly and rotating

out of the freezer barrel. As the auger is with

drawn, remove each plastic flight and spring from

the auger. (Fig.14)

NOTE

Be careful not to scratch inside of the freezer barrel

when removing flights or augers.

6. Remove the rear seal assembly.

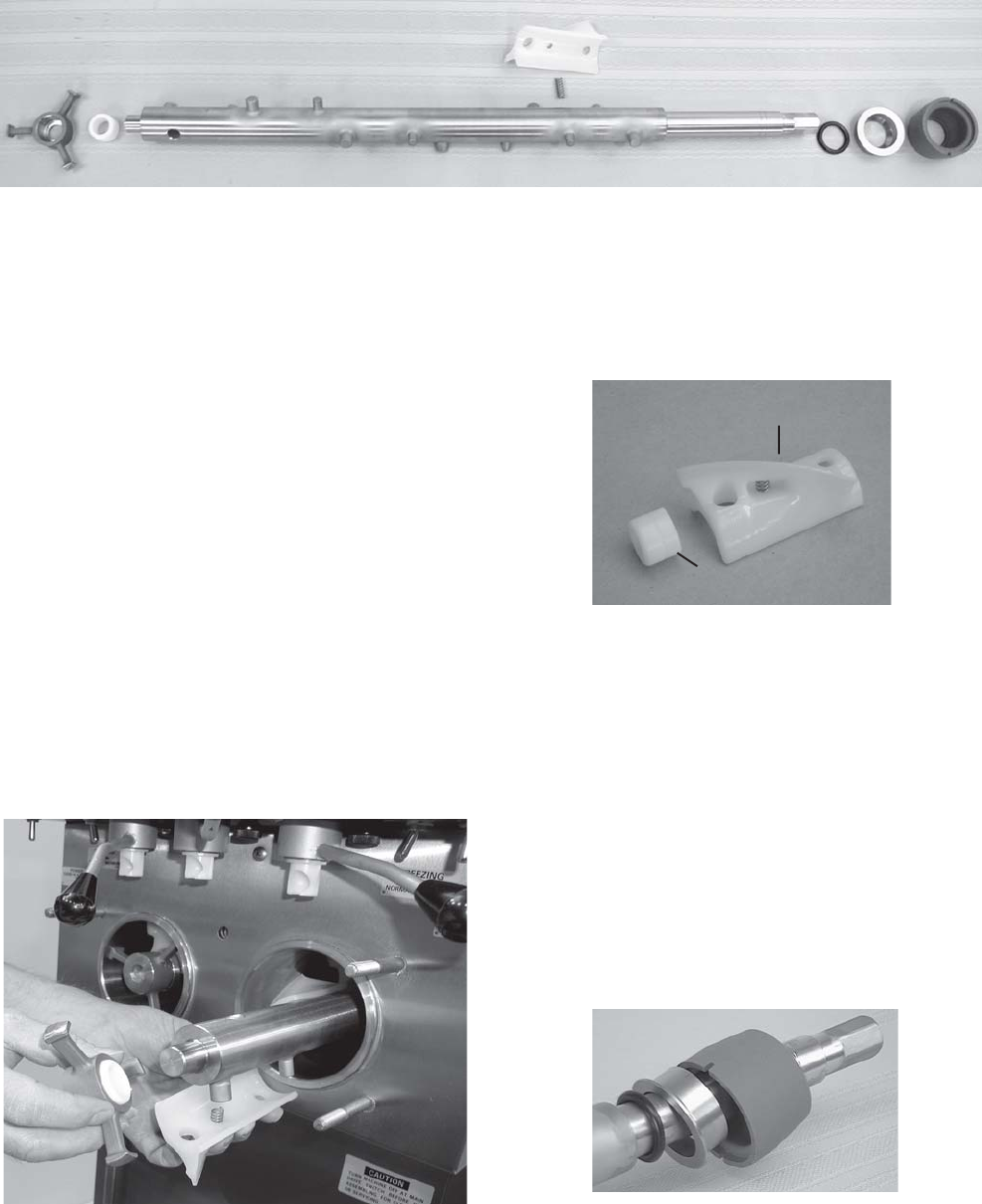

7. After proper cleaning, inspect plastic parts and

rear seal parts for wear and damage. (See Fig.

15)

Auger Flight

Front Auger Bearing

Figure 15. Plastic Parts

B. Assembly of Auger

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of parts is specified.

1. Install O-ring onto auger shaft dry (without lubrica

tion).

2. Lubricate the O-ring and the inside of the rear

seal adapter with a thin film of sanitary lubricant.

3. Install the rear seal adapter and seal in order as

shown in Figure 16.

Figure 16. Auger Assembly

4. Lubricate the hex drive end of auger with a small

amount of white spline lubricant.

NOTE

A small container of socket lubricant is shipped with

the freezer.