3

SECTION 2

INSTALLATION

2.1 SHIPMENT AND TRANSIT

The freezer has been assembled, operated, and inspected

at the factory. For shipment, the freezer is placed on skids,

with small parts placed separately in boxes. Upon arrival

at the final destination, the freezer must be checked for

any damage which may have occurred during final transit.

With the sturdy packaging used, the equipment should

arrive in satisfactory condition. THE CARRIER IS

RESPONISIBLE FOR ALL DAMAGE IN TRANSIT,

WHETHER VISIBLE OR CONCELAED. Do not pay the

freight bill until you have checked the equipment. Have

the carrier note any visible damage on the freight bill. If

concealed damage and or shortage is found later advise

the carrier within ten days and request inspection. The

customer must place claim for damage and/or shortages

in shipment with the carrier. Stoelting, Inc. cannot make

any claims against the carrier.

2.2 INSTALLATION

Installation of the freezer involves moving the freezer close

to its permanent location, removing all protective packag-

ing, setting in place and cleaning.

A. Remove all protective packaging. Remove the hold

down bolts from the wooden pallet, and walk freezer

off the pallet.

B. The freezer is shipped without legs. To install legs,

lift freezer and screw caster, extension, or leg into

the bottom of frame at each corner. Refer to caster

and leg options in Figure 1.

Figure 1. Caster Options

For Models DQ217, 217R, 225R, 237R

WARNING

FREEZER MUST NOT BE ALLOWED TO TIP

MORE THAN 10°. FAILURE TO HEED THIS WARN-

ING COULD RESULT IN THE FREEZER FALLING

ON IT’S SIDE CAUSING SERIOUS DAMAGE OR

INJURY.

C. To level turn the top part of the caster or the bottom

part of the leg in or out. Then level by placing a level

on top of the freezer at each corner.

NOTE

Leveling is necessary for correct freezer drainage.

D. For all freezers allow a minimum of 6 inches of space

at the front and rear for air circulation. For efficient

operation, the room temperature should not be be

low 60° F (16° C) or above 90° F (32° C).

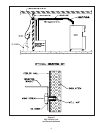

E. For water cooled freezers, install a minimum of 1/2

inch pipe or 5/8 inch inside diameter copper water

line to the freezer. The water line must be connected

in a manner that will comply with local codes and

allow adequate room for servicing.

NOTE

All external plumbing is to be supplied by the customer.

Water lines connect to fittings at the rear of the freezer.

(See Fig.2) Connect the clean, potable, water inlet to water

source using flexible high water pressure line. Ordinary

garden hose is not recommended. Connect the water out-

let to flexible plastic tubing. The outlet can be secured to

floor drain, as the outlet is clean, warm water.

Option B - Casters & ExtensionsOption A - Casters