12

NOTE

Stoelting has found that stera-sheen green label

sanitizer and cleaner does an effective job of prop-

erly sanitizing and cleaning soft serve freezers. A

sample is included with each new freezer. Read di-

rections on packet, for more information. Other prod-

ucts may be as effective.

CAUTION

PROLONGED CONTACT OF SANITIZER WITH

FREEZER MAY CAUSE CORROSION OF STAIN-

LESS STEEL PARTS.

ANY DISINFECTANT MUST BE USED ONLY IN

ACCORDANCE WITH THE MANUFACTURER’S

INSTRUCTIONS. IN GENERAL, SANITIZING MAY

BE CONDUCTED AS FOLLOWS:

A. Clean and lubricate parts.

B. Use a sanitizer mixed according to manufacturer’s

instructions to provide a 100 parts per million strength

solution. Mix sanitizer in quantities of no less than 2

gallons (7.5 liters) of 120° F water. Allow the sani-

tizer to contact the surfaces to be sanitized for 5

minutes.

F. Check for leaks at three points when the freezer

barrel is first pressurized with sanitizing solution.

1. Check for leaks at the plastic front door O-rings

may not be sealing.

2. Open access door on the side panel. Make sure

the rear seal is not leaking.

3. Check in the hopper (hopper models) to see that

no bubbles are around the discharge end of the

mix transfer tube.

G. Using a sanitized soft bristle brush or equivalent,

dipped in sanitizing solution, clean mix container

(remote models) or sides of hopper, exterior of pump,

and underside of hopper cover (hopper models).

H. After five minutes, open spigot to expel sanitizing

solution. Drain all solution from freezer.

I. Close the spigot and place the mix pump switch and

the POWER switch in the OFF position.

The freezer is now sanitized and ready for adding mix.

3.13 INITIAL FREEZE DOWN AND OPERATION

This section covers the recommended operating proce-

dures to be followed for the safe operation of the freezer.

A. Sanitize just prior to use according to instructions in

section 3.11.

B. Prepare the desired amount of mix and then fill hop-

per (hopper models) or storage container (remote

models) with approximately three gallons (11 liters)

or more of mix.

NOTE

Hopper models must not be filled to more than 2"

(5 cm) from the top.

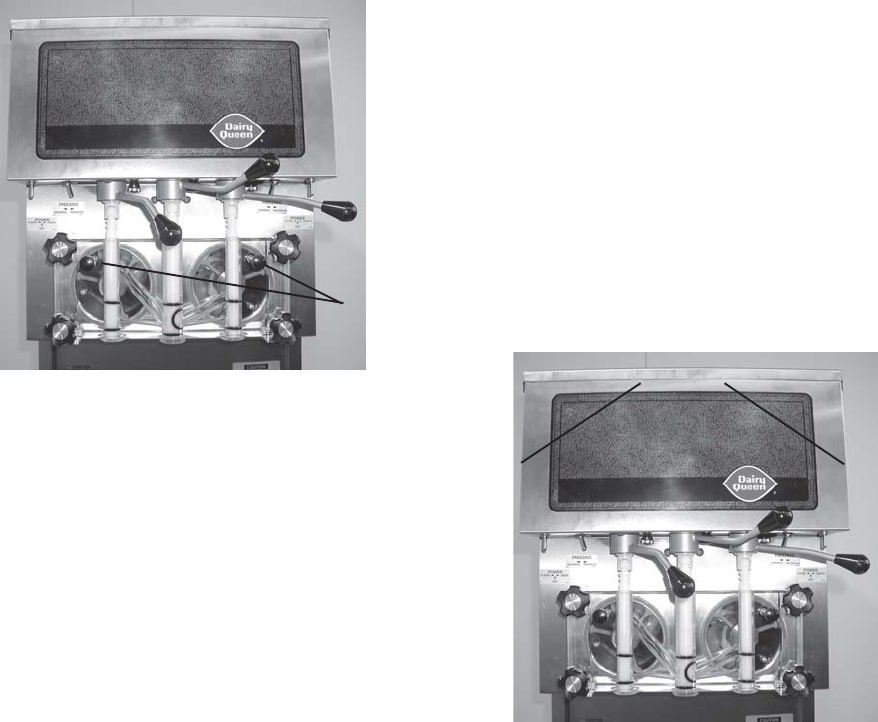

Figure 9. Air Bleed

Sanitizer must be used only in accordance with the

manufacturer’s instructions. Pour into hopper (hop-

per models) or storage container (remote models).

C. Place the mix pump switch in the ON position and

open air bleed valve on the front door by pushing

valve in and holding. (See Fig.9)

D. Let sanitizing solution fill the freezer barrel to air bleed

valve, then close the valve by pulling out to lock in

place.

E. Place the MAIN DRIVE switch in the CLEAN

position.

Figure 10. Pump Switch

Air

Bleed

Pump Switch