5

CAUTION

FLUSH ALL WATER LINES BEFORE INSTALLA-

TION. IN NEW STORES WITH SEDIMENT IN

WATER, ADD SUITABLE FILTER OR STRAINER

TO WATER INLET. FAILURE TO FLUSH ALL

WATER LINES MAY RESULT IN EQUIPMENT

FAILURE AND EQUIPMENT DAMAGE.

F. Refer to nameplate at the side of the freezer for

specific electrical requirements. Connect electrical

power to the junction box at the rear of the freezer.

Bring wires into junction box through access hole in

bottom rear of freezer. (Fig.3).

ATTENTION

The 24V AC pilot circuit is wired for a 240V supply.

If this freezer is installed in a location with a 208V

supply the transformer must be rewired. Remove

the left and right side panel to access.

CAUTION

ELECTRICAL TECHNICIANS MUST BE CONTINU-

OUSLY ALERT TO THE PRACTICE OF ALL NEC-

ESSARY SAFETY RULES AND PRECAUTIONS

WHEN SERVICING THIS EQUIPMENT AS VOLT-

AGES ARE PRESENT WHICH CAN CAUSE SERI-

OUS OR FATAL INJURY.

ELECTRICAL WIRING MATERIALS, ARRANGE-

MENT AND GROUNDING MUST CONFORM WITH

NATIONAL AND OTHER APPLICABLE ELECTRI-

CAL CODES.

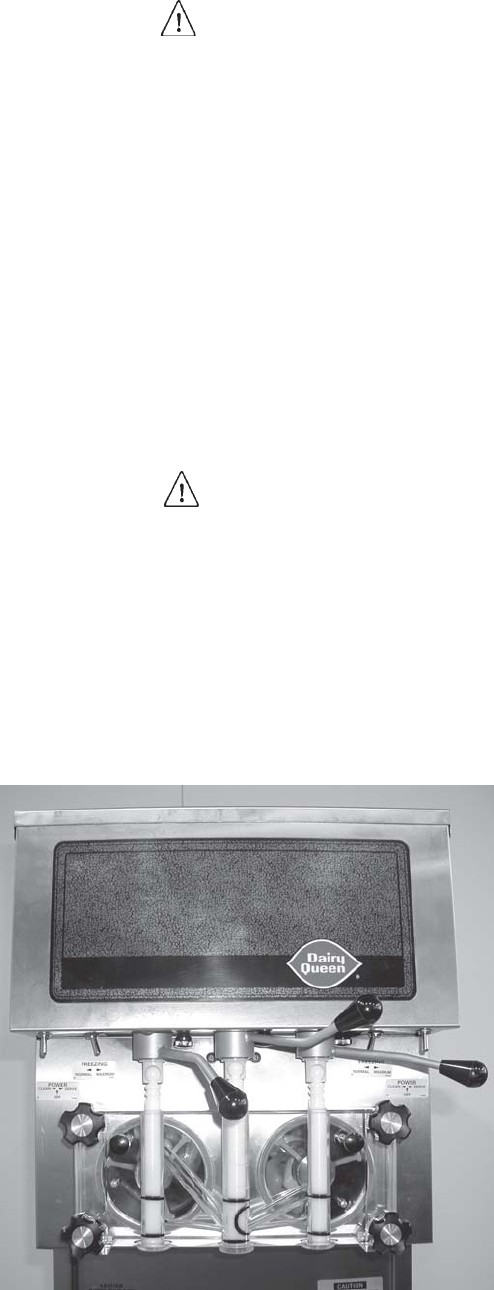

Figure 4

Auger Shaft Rotation

G. Check the auger shaft rotation by placing the MAIN

DRIVE switch in the CLEAN position. Auger shaft

rotation is clockwise as viewed through the clear plas-

tic front door. If the rotation is not clockwise, turn

main electrical power OFF. Then reverse any two

electrical power lines in the junction box (three phase

only). Recheck auger shaft rotation. (Fig.4)

NOTE

Three phase freezers in areas of unbalanced elec-

trical loads require special attention when connect-

ing input electrical power. The unbalanced leg of

power (called wild or high) must be connected to L2

in the junction box.

H. Remote fed freezers require an approved 1/2 inch

(12.7 mm) I.D. refrigerated mix transfer tube from

mix pump in walk in cooler to mix inlet at top of

freezer. Clamp both ends of tubing. Support to

prevent sagging and to promote total drainage when

not in use.

NOTE

Refer to the mix pump manual for complete infor-

mation on the operation of the mix pump.

2.3 REMOTE CONDENSER

The remote condenser can be installed either indoors or

outdoors without additional protection required. Horizon-

tal installation requires the liquid line connection to be

made at the bottom of the coil. There should be no ob-

structions to the fan within five feet of the discharge.

NOTE

There must be an adequate supply of ambient air

below 120° F (49° C). Operating above this tem-

perature will result in loss of capacity. Guard against

recirculation due to discharge into an overhang roof

or the side of the building.

A. Connect 230VAC, 60HZ, 1-PH to run the 1/6 HP,

2.8 AMP fan motor.

B. Connect refrigerant lines. Use 3/8 inch (9.52 cm)O.D.

copper line only. Trap hot gas line as shown (Fig.5).

Do not trap liquid line at all. If condenser is below

the freezer, no traps are required. (Fig.5)

NOTE

Maximum line length is 50 feet (15.24 meters).