©2003 Maytag Appliances Company 16022785 Rev. 0 7

For proper operation at altitudes above

2,500 feet

The natural gas valve spud orifice size must be reduced to

ensure complete combustion. See table.

Altitude

Ft (M)

Orifice

Size #

Part

number

3000 (915) 43 503778

6000 (1830) 44 58719

8000 (2440) 45 503779

9000 (2740) 46 503780

10000(3050) 47 503781

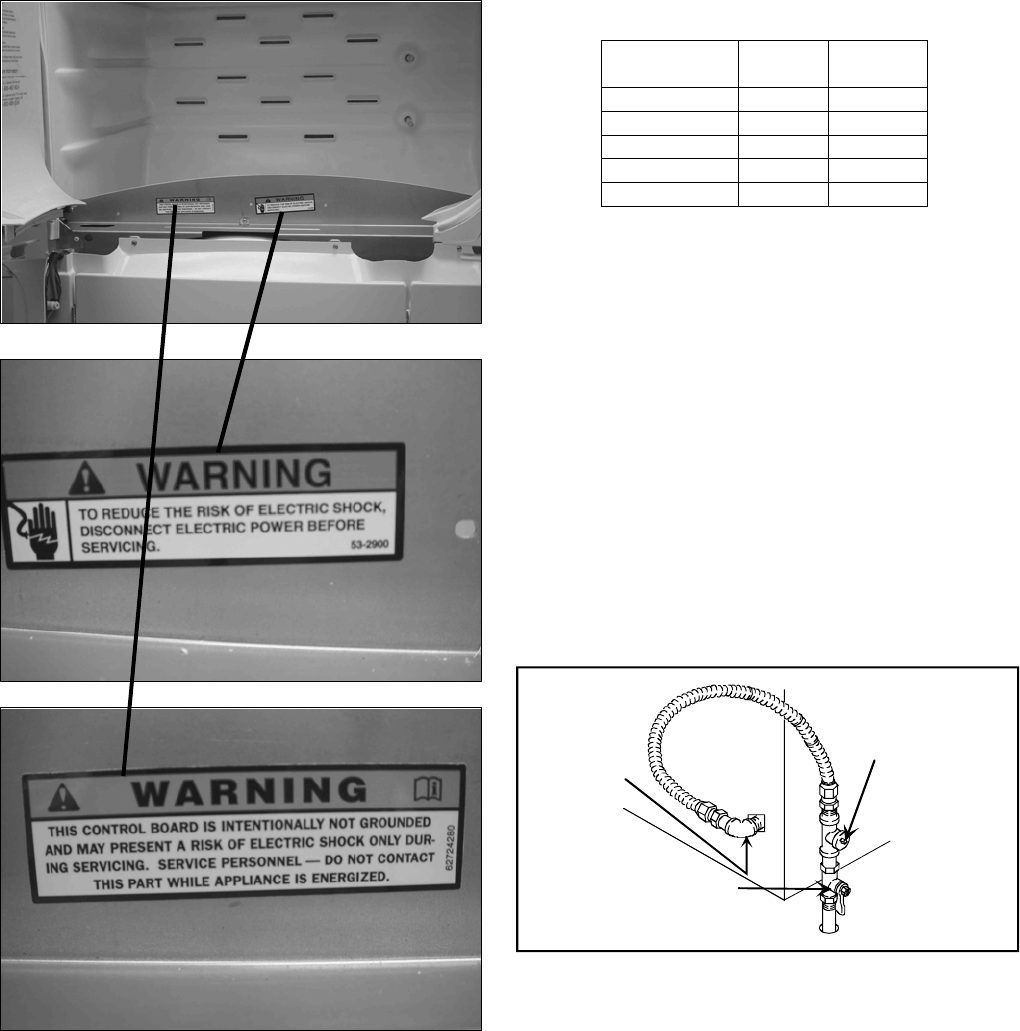

Gas Connection

Connect gas supply to dryer using a new stainless steel

flexible connector or hard pipe (check local codes)

according to illustration. Test for leaks and check burner

flame after gas supply is connected.

• Dryer must be connected to type of gas as shown on

nameplate located in the door recess.

• Use pipe joint compound insoluble on LP (propane)

Gas, or Teflon tape, on all pipe threads.

• Purge air and sediment from gas supply line before

connecting it to the dryer. Before tightening the

connection, purge remaining air from gas line to dryer

until odor of gas is detected. This step is required to

prevent gas valve contamination.

Use a new stainless steel flexible connector only if

allowed by local codes (use A.G.A. certified connector).

3/8" NPT gas

connection

1/8" NPT pipe plug

(for checking inlet

gas pressure)

Install Equipment

shut-off valve

within 6' (1.8 m) of dryer.

Black iron piping:

• Shorter than 20’ (6.1 m) – use 3/8” piping

• Longer than 20’ (6.1) m) – use 1/2” piping

Testing for Gas Leaks

After final gas connection is made, turn on manual gas

valve and test all connections in gas supply piping for gas

leaks. Leak testing of the appliance shall be conducted

according to the manufacturer’s instructions.

1. Place soap suds on connections.

2. If bubbles appear, a leak is present. Shut off gas

supply valve.

3. Tighten joint if leak is at factory fitting.

• If leak is not at factory fitting, unscrew, apply more

joint compound, and tighten to correct leak.

Important Safety Information